Preventive Maintenance Program

XPR Instruction Manual 809480 19

Be careful that you do not pinch the wires between the cover and the

center panel.

Examine the coolant system

Examine the coolant system for coolant leaks at all connections. Make sure you examine:

The gas connect console

The torch connect console

The torch main body

The internal connection in the plasma power supply

Do the coolant flow test

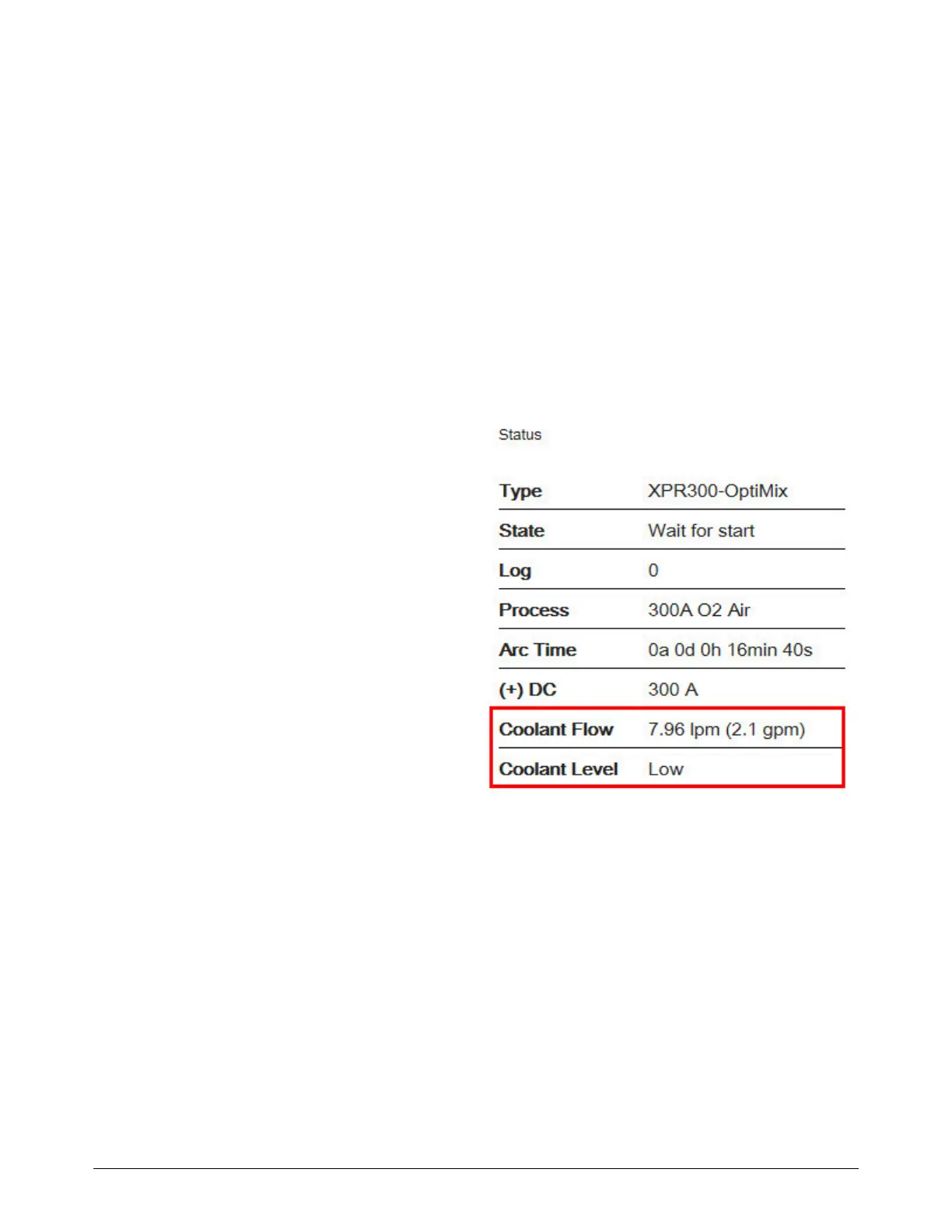

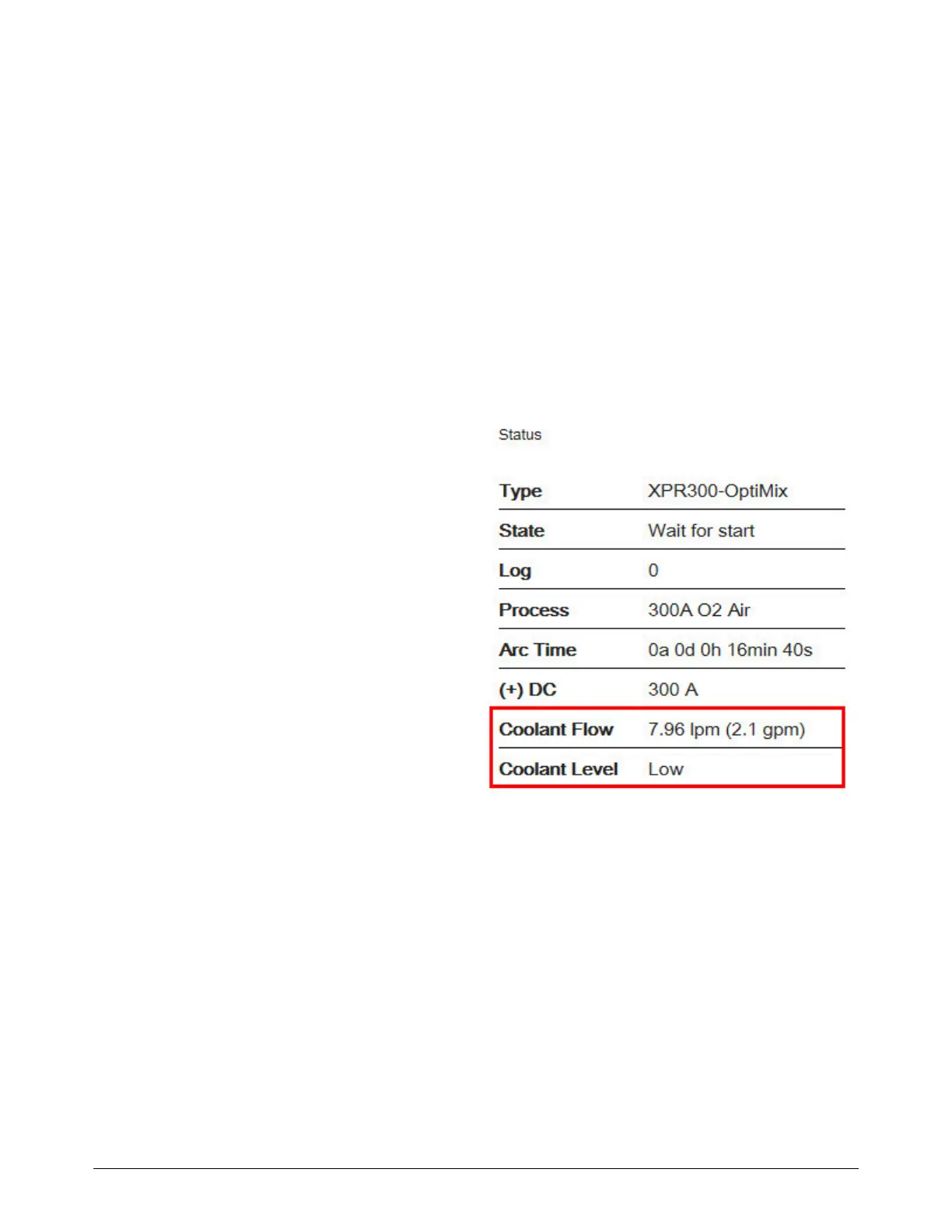

1. Look at the CNC or plasma power

supply screen on the XPR web interface

to identify the coolant flow rate.

Shown for reference only.

2. Make sure that the coolant flow rate is

acceptable:

Between 3.79 L/min – 11.36 L/min

(1 gal/min –3.0 gal/min) for an

XPR170 cutting system.

Between 3.79 L/min – 9.46 L/min

(1 gal/min – 2.5 gal/min) for an

XPR300 cutting system.

If the flow rate is outside of the

correct range, an internal

obstruction can be the cause.

3. If you find obstructions, remove them. Replace damaged parts if found.

4. If coolant flow remains slow, and it has been more than 6 months since the last coolant

replacement, replace the coolant. See Replace the coolant and coolant filter, and clean and

examine the pump screen on page 21.

Hypertherm recommends coolant replacement every 6 months.

5. If the coolant flow remains slow, see How to measure coolant flow in your system’s instruction

manual.

6. If you cannot find or resolve the problem with these corrective actions, contact your cutting

machine supplier or regional Hypertherm Technical Service team.

Loading...

Loading...