1-15

INSTALLATION

SL 80-399 MODULATING GAS BOILER

SL 26-260 G3, SL 40-399 G3 MODULATING GAS BOILERS

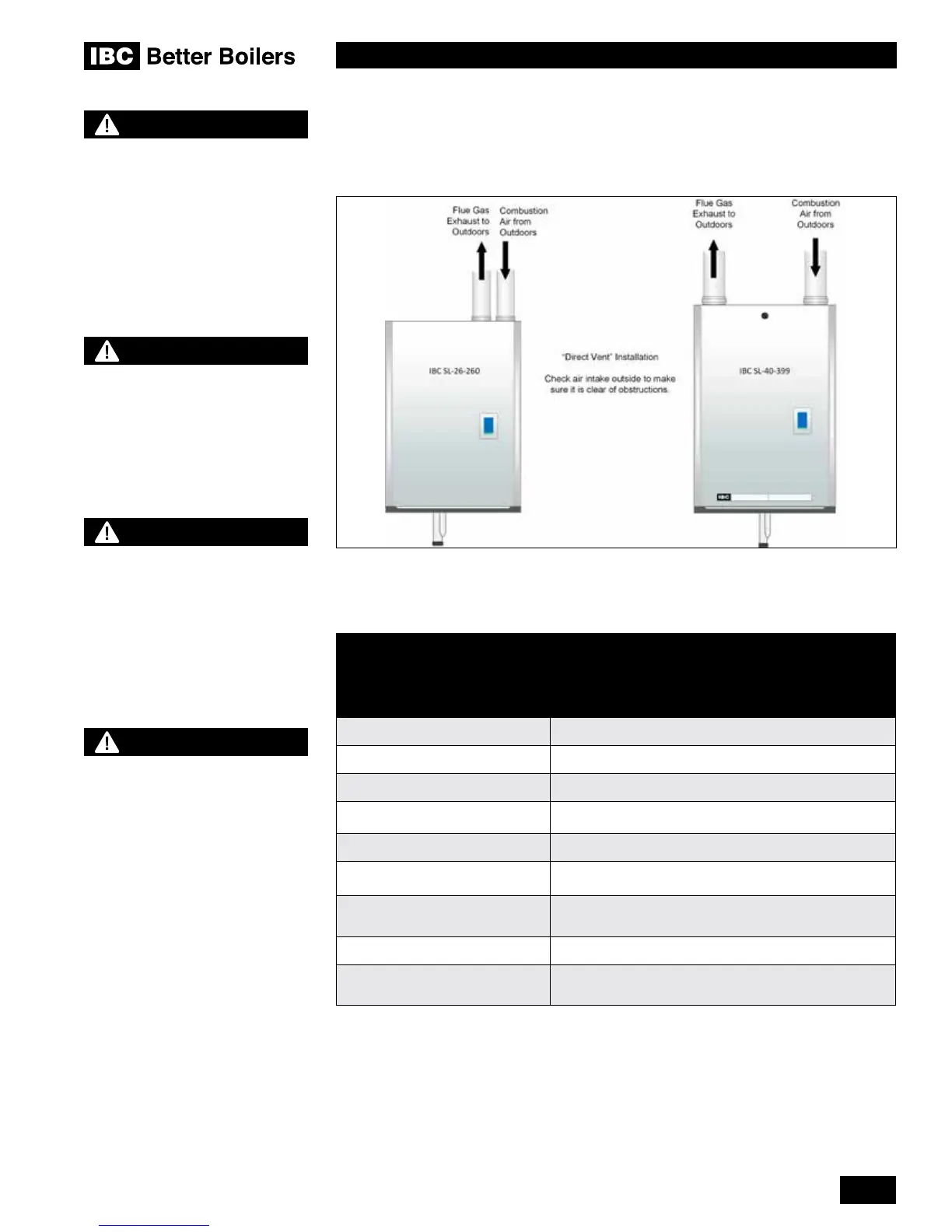

1.4.7 “Direct Vent” Combustion Air Intake Piping

The direct vent option uses piping from the outside to supply combustion air directly to the

boiler’s combustion air connection.

Figure 18: Direct vent combustion air intake

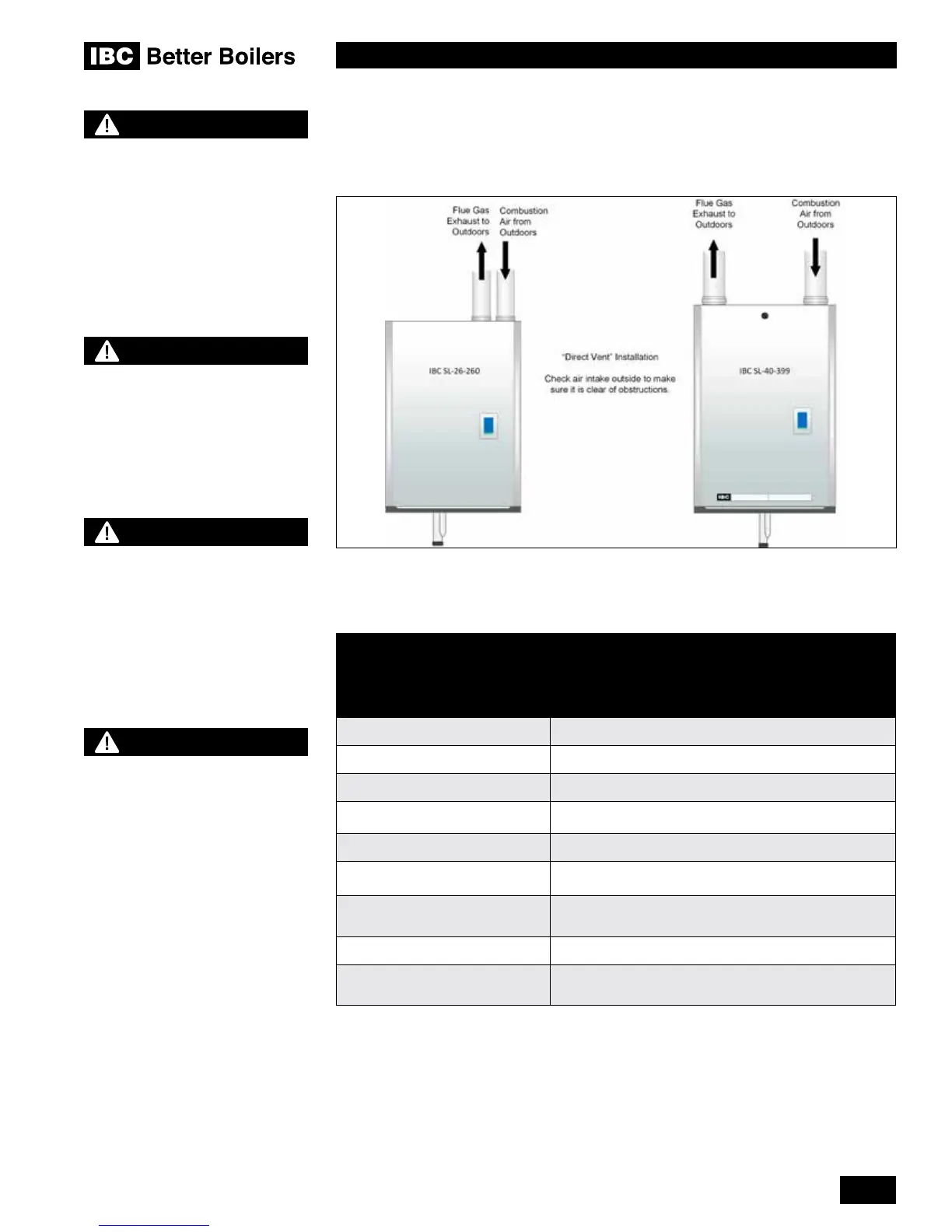

SL 26-260 G3

INTAKE PIPE SIZE MAXIMUM EQUIVALENT LENGTH

Sched.40; Rigid PPs

3" 200' each side

90° vent elbow allow 8' equivalent

90° long sweep elbow allow 5' equivalent

45° elbow allow 3' equivalent

PPs 87-90° elbows use 8' equivalent

3" Stainless Sidewall Terminal

IBC P/N 180-149 (P-257)

No additional allowance required

Flexible PPs

3" PPs Flexible (SL 26-260

G3)

60' max., actual lineal x 3.33 = equivalent

Table 4A: Maximum Intake Pipe Venting Length for SL 26-260 G3

WARNING

In addition to preventing

ingestion of chemical

contaminants, care must be

taken to ensure air intake

terminals are not installed in

locations where contamination

might occur due to ingestion of

particulate foreign material (dust,

dirt and debris).

NOTE

Care must be taken when

installing air intake piping to

ensure that a “trap” is not formed

in the piping so as to allow a

build-up of water, and blockage

of intake air.

Such blockage will result in a

boiler safety shut-down.

WARNING

Intake air openings must be

congured such that rain or

other forms of moisture cannot

enter the air intake piping

system. Otherwise serious

damage to the boiler may result.

NOTE

Combustion fan blockages

can occur when environmental

particulate and foreign matter

contaminants (leaves, dust,

dandelion & cottonwood uff,

etc) are drawn into the air intake.

In areas where this problem

is suspected to be an issue,

intake air ltration should be

considered. Contact Factory.

Filters should be checked and

cleaned or replaced on a regular

schedule based on the severity

of the problem.

Loading...

Loading...