Two- Stage Multi Position Furnace

Service

Manual

9

440 08 2002 02

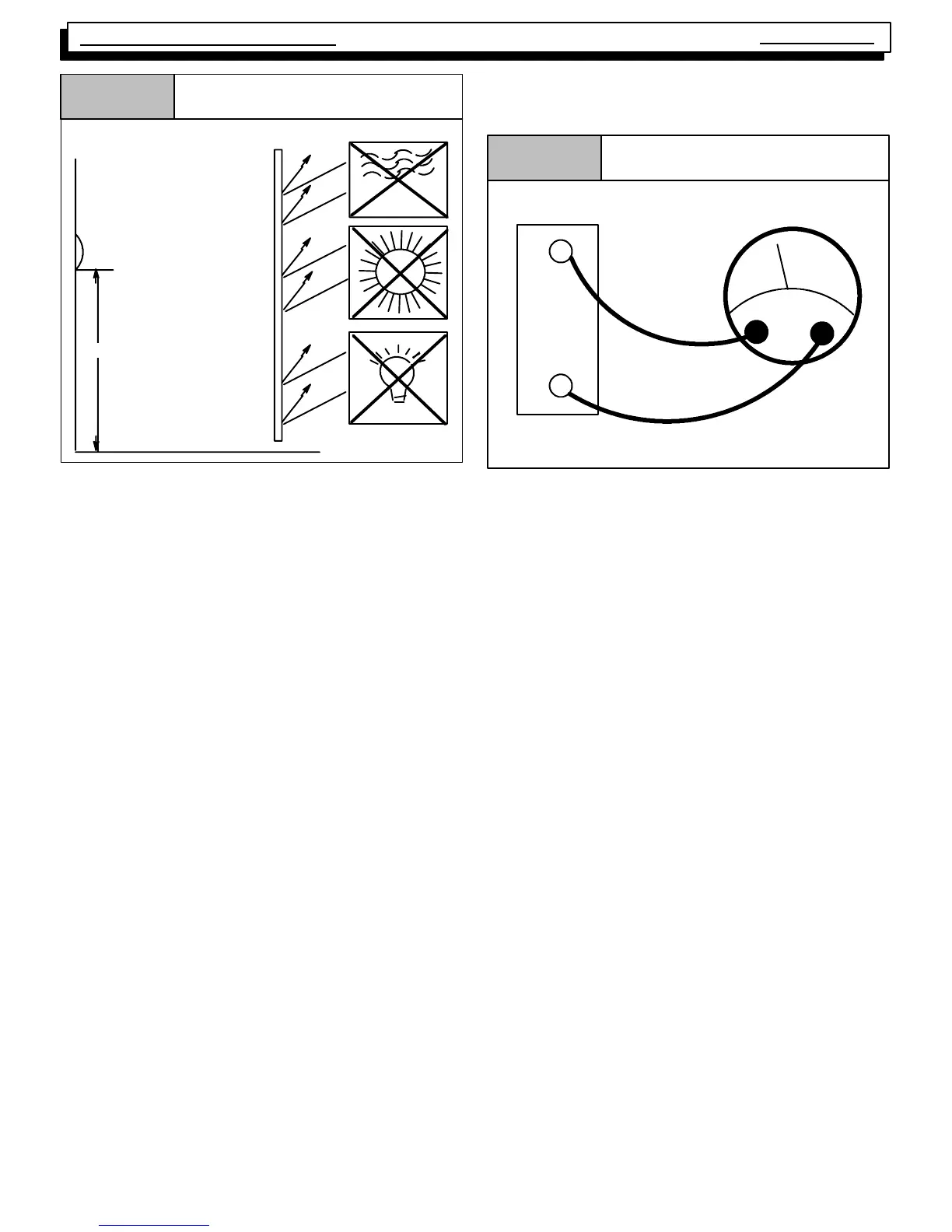

Thermostat Location

Figure 9

5 ft.

DRAFTS

SUN

THERMOSTAT

LIGHT

SHIELD

LOCATION

The thermostat should not be mounted where it may be af-

fected by drafts, discharge air from registers (hot or cold), or

heat radiated from the sun of appliances. Never install in al-

coves, bathrooms or bedrooms.

The thermostat should be located about 5 ft. above the floor

in an area of average temperature, with good air circulation.

Normally, an area in close proximity to the return air grille is

the best choice.

Mercury bulb type thermostats MUST be level to control tem-

perature accurately to the desired set--point. Electronic digi-

tal type thermostats SHOULD be level for aesthetics.

HEAT ANTICIPATORS

Heat anticipators are small resistance heaters built into most

electric--mechanical thermostats. Their purpose is to pre-

vent wide swings in room temperature during furnace opera-

tion.

In order to accomplish this, the heat output from the anticipa-

tor must be the same regardless of the current flowing

through it. Consequently, most thermostats have an adjust-

ment to compensate for varying current draw in the thermo-

stat circuit.

The proper setting of heat anticipators then is important to

insure proper temperature control and customer satisfac-

tion.

The best method to obtain the required setting for the heat

anticipator, is to measure the actual current draw in the con-

trol circuit (“W”) using a low range (0--2.0 Amps) Ammeter.

(See Figure 10) After measuring the current draw, simply

set the heat anticipator to match that value.

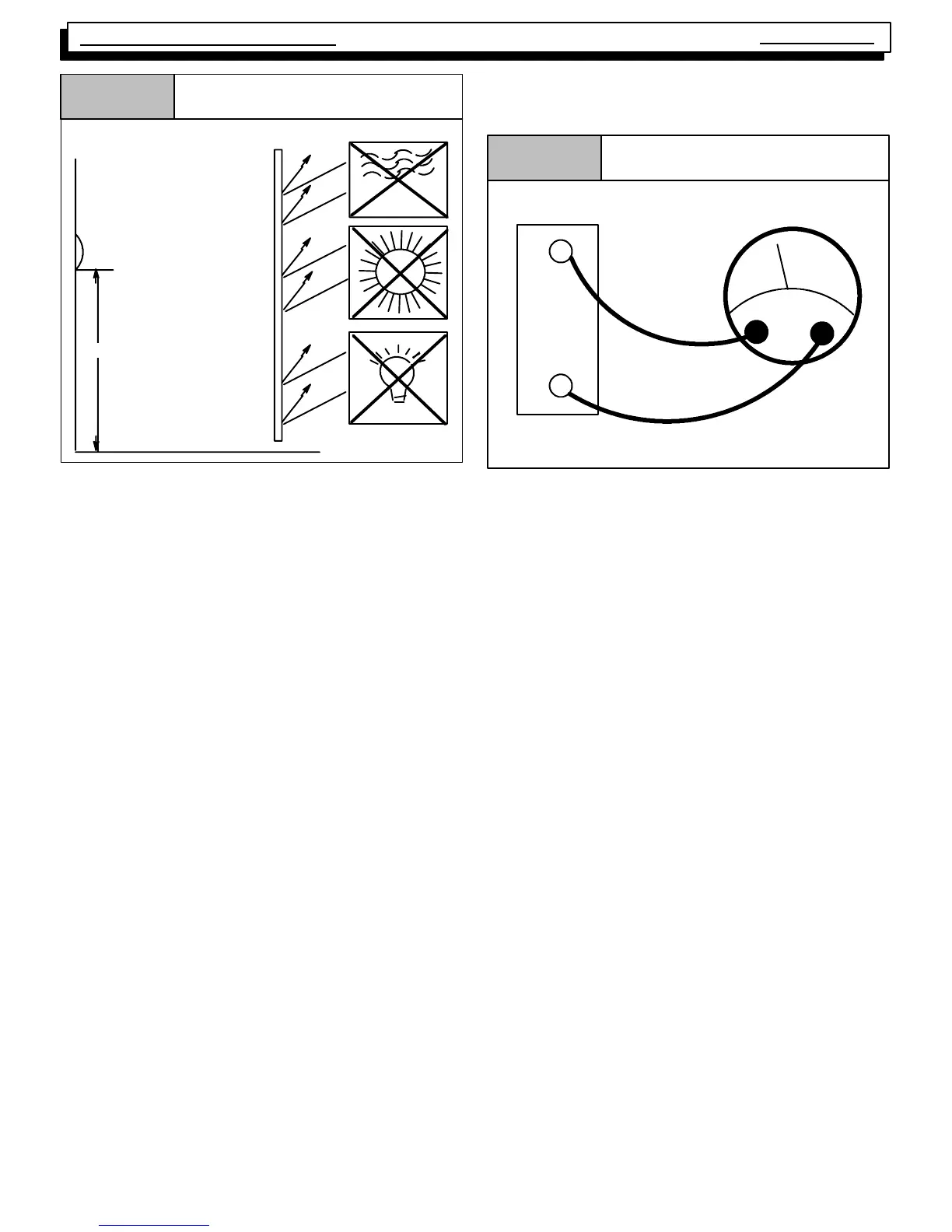

Measuring Current Draw

Figure 10

Ammeter

W

R

Subbase

Amps

If a low range ammeter is not available, a “Clamp--on” type

meter may be used as follows:

1. Wrap EXACTLY ten (10) turns of wire around the jaws

of a clamp--on type ammeter .

2. Connect one end of the wire to the “W” terminal of the

thermostat sub--base, and the other to the “R” termi-

nal.

3. T urn power on, and wait approximately 1 minute, then

read meter.

4. Divide meter reading by 10 to obtain correct anticipator

setting.

NOTE: For 2 Stage heating thermostats the above proce-

dure MUST be perf ormed twice. O nce f or first

st age ( W

1), and once for second st age (W2), if

both stages have adjustable heat anticipators.

If an ammeter is not available, a setting of 0.10 amps may

be used for models equipped with the HONEYWELL

SV9541Q Gas Valve/Ignition Control. They should, howev-

er, provide satisfactory operation in most cases.

Electronic thermostats do not use a resistance type anticipa-

tor. These thermostats use a microprocessor (computer)

that determines a cycle rate based on a program loaded into

it at the factory.

These cycle rates are normally field adjustable for different

types to equipment. The method of adjustment, however,

varies from one thermostat manufacturer to another. Check

with the thermostat manufacturer to find out the proper way

of adjusting the cycle rate.

Loading...

Loading...