Two- Stage Multi Position Furnace

Service

Manual

12

440 08 2002 02

14. PRESSURE SWITCHES

TRANSITION PRESSURE SWITCH

Under normal operating conditions, sufficient pressure is de-

veloped by the exhaust (combustion) blower to close the

switch, and permit the burner to operate. As the condensate

drain begins to back--up, however , the pressure begins to re-

duce. When the pressure drops sufficiently, burner operation

will be prevented until the condition is corrected.

STANDARD PRESSURE SWITCHES - ALL

MODELS

Model

Max.

Close

Open Part #

Condensing

50, 75 &100

--1.70² W.C.

--1.50 + 0.10² W.C.

--

125

--2.00² W.C.

--1.80 + 0.10² W.C.

--

Always check current “Technical Support Manual”for

Part Nos.

BLOWER PRESSURE SWITCH

An air proving switch (pressure switch) is used on all models

to insure that a draft has been established through the heat

exchanger before allowing burner operation.

To insure continued SAFE, RELIABLE, operation, NEVER

SUBSTITUTE a pressure switch with one that is similar in

appearance. ONLY FACTOR Y PROVIDED or

AUTHORIZED SUBSTITUTES ARE ACCEPTABLE.

All models installed at altitudes of 4,000¢ above sea level or

higher require replacing the standard pressure switch with a

high altitude pressure switch. The different pressure switch

settings allow continued SAFE, RELIABLE, high altitude

operation.

Note: T ransition switch checks lo--fire airflows & blocked

condensate. Blower switch checks Hi--fire airflow.

HIGH ALTITUDE PRESSURE SWITCHES - ALL

MODELS

Model

Max.

Close

Open Part #

Condensing

50, 75 &100

--1.40² W.C.

--1.20 + 0.10² W.C.

--

1013165

125

--1.70² W.C.

--1.50 + 0.10² W.C.

--

1013157

Always check current “Technical Support Manual”for

Part Nos.

Under normal operating conditions, sufficient negative pres-

sure will be created to close the pressure switch, and keep

it closed to keep furnace operating. Under abnormal condi-

tions, however , such as a restricted vent pipe, or a leak in one

of the heat exchangers, sufficient negative pressure will not

be created. This will result in the switch failing to close or fail-

ing to remain closed during furnace operation.

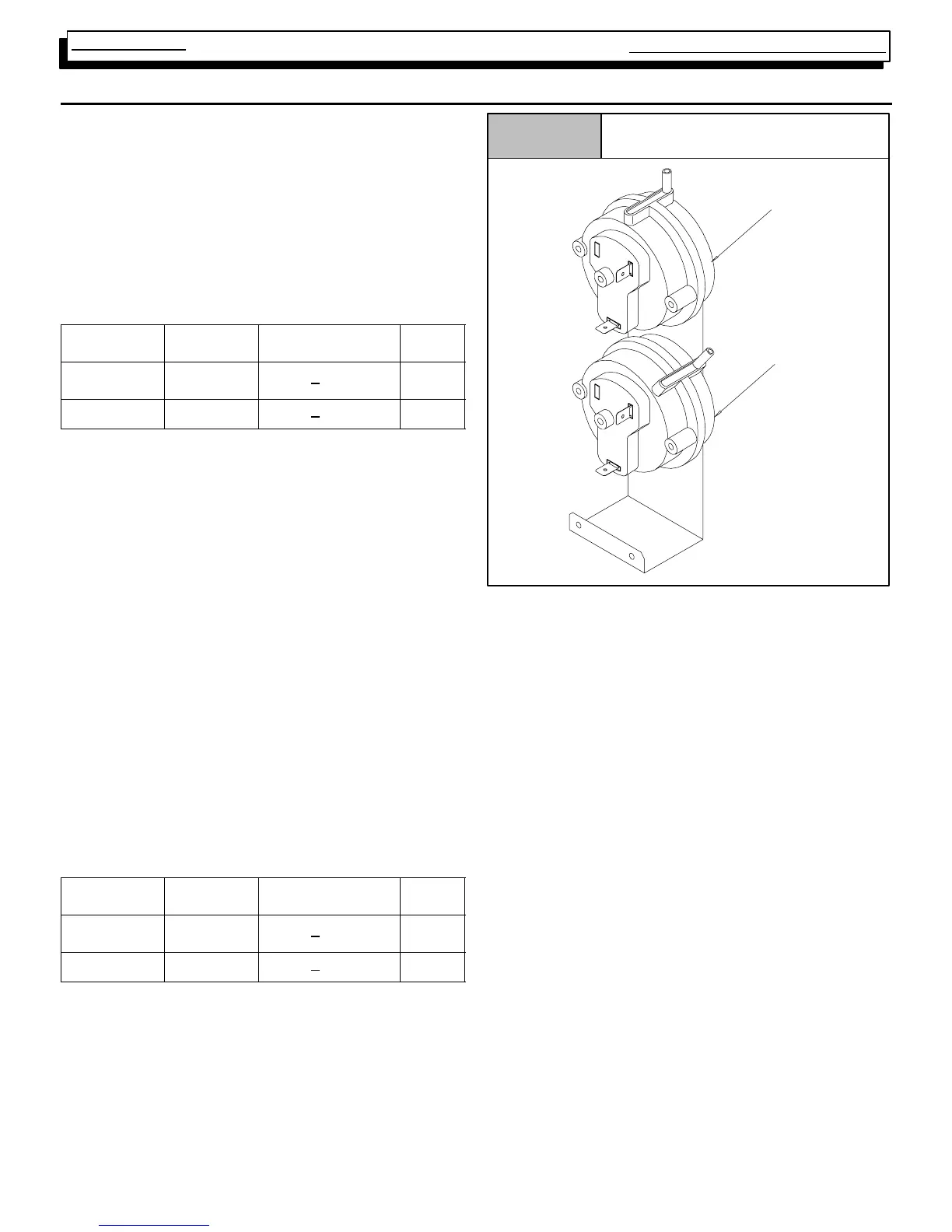

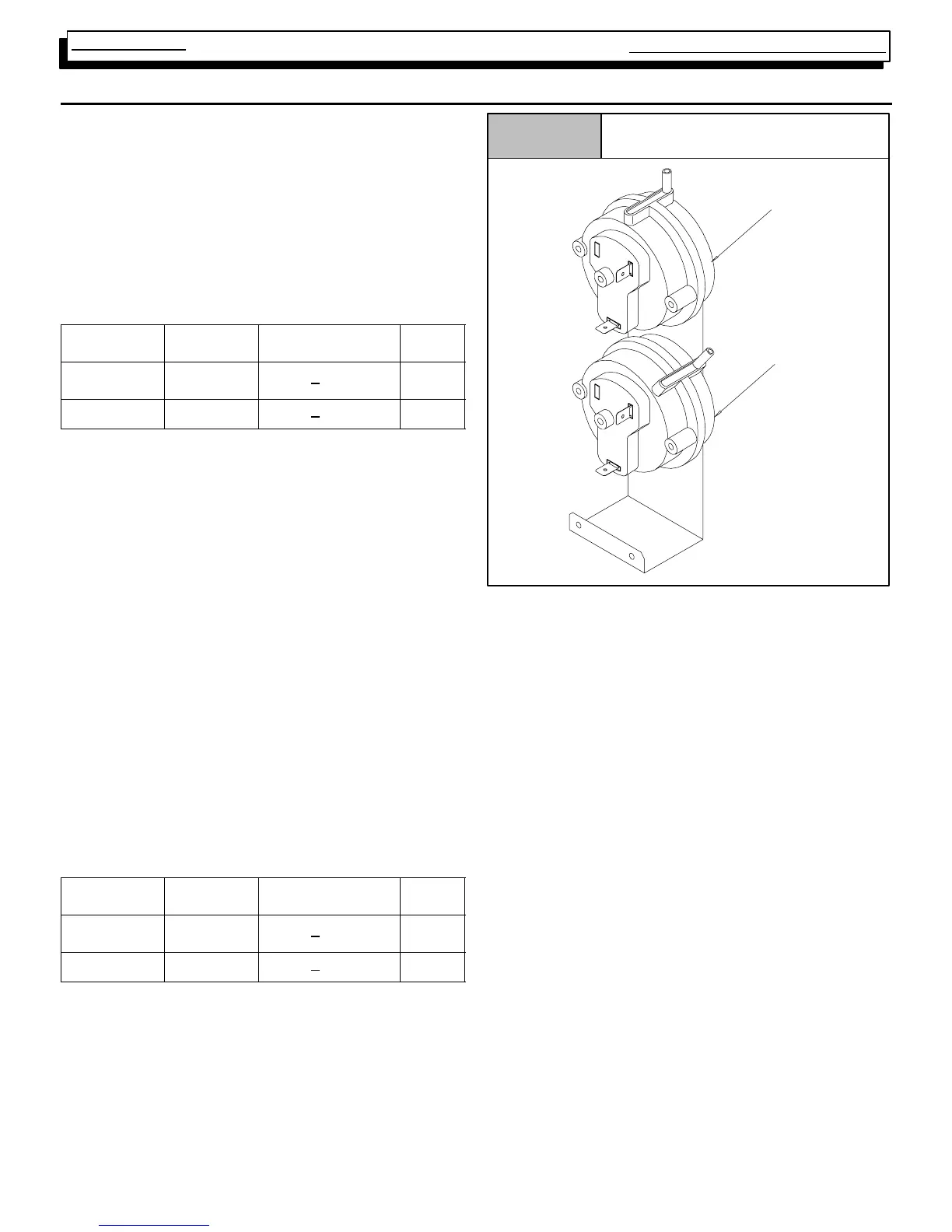

Pressure Switches

Figure 13

25--23--72

T ransition

(Lo--fire)

Blower

(Hi--fire)

When servicing a unit whose pressure switch will not close,

or remain closed during operation, the operating pressure of

that furnace should be checked and compared to

approximate operating pressures listed in Table 3 and the

switch setting(s) listed above for the model family you are

servicing.

It is important to remember , that greater negative pressures

are created by the furnace when “Hot” (I.E. upon initial start--

up) than when “Cold” (I.E. after furnaces has been in opera-

tion for a few minutes). Because of this, furnace pressure

should ONLY be checked when “HOT” to insure accurate

readings.

Table 3 lists approximate operating pressures for Direct

Vent (I.E. Two Pipe) installations of models in this series.

They were obtained in a test lab, under controlled conditions

using two (2) specific vent lengths. They are included in this

manual to provide you with a “Barometer” to gauge our pres-

sures against. The pressures you obtain in the field will differ

slightly from these figures based upon vent length, gas pres-

sure, operating temperature, etc.

Major discrepancies in pressures, will normally cause

problems with pressure switch operation. These Major dis-

crepancies should be investigated as follows:

Loading...

Loading...