Two- Stage Multi Position Furnace

Service

Manual

2

440 08 2002 02

1. INTRODUCTION

This service manual is designed to be used in conjunction

with the installation manual and/or technical support manual

provided with each furnace.

These furnaces represent the very latest in high efficiency

gas furnace technology. Consequently, they incorporate the

use of certain controls that contain highly sophisticated elec-

tronic components which are not user serviceable. there-

fore, it is essential that only competent, qualified, service

personnel attempt to install, service, or maintain this prod-

uct.

This Service manual was written to assist the professional

HVAC service technician to quickly and accurately diagnose

and repair any malfunction of this product.

This service manual covers several different models in two

(2) families of our new multi--position furnaces; Variable

Speed (D.C.-- Blower Motor) models in the Condensing fur-

nace family, and 2 speed (P.S.C.--Blower Motor) models in

both the Condensing and Non--Condensing furnace families.

The overall operation of all of these models and families is

essentially the same, with the exception of the Blower Motor,

and/or certain control functions which may be unique to a

particular model and/or family.

This manual, therefore, will deal with all subjects in a general

nature (I.E. all text will pertain to all models) unless that sub-

ject is unique to a particular model or family, in which case

it will be so indicated.

Throughout the manual references may be made to “VARI-

ABLE SPEED MODELS” as well as “TWO SPEED MOD-

ELS”. GENE RALLY, t he distinc t ion between thes e two

groups is based on a difference in the type of Blower Motor

used. T hese may not be the only diff erenc es, however,

and the differences may vary from model to model within a

particular family or series.

It will be necessary then for you to accurately identify the

unit you are servicing, so you may be certain of a proper

diagnosis and repair. (See Unit Identification, Page 3)

The information contained in this manual is

intended for use by a qualified service technician

who is familiar with the safety procedures required

in installation and repair and who is equipped with

the proper tools and test instruments.

Installation or repairs made by the unqualified

persons can result in hazards subjecting the

unqualified person making such repairs to the risk of

injury or electrical shock which can be serious, or

even fatal not only to them, but also to persons being

served by the equipment.

If you install or perform service on equipment, you

must assume responsibility for any bodily injury or

property damage which may result to you or others.

We will not be responsible for any injury or property

damage arising from improper installation, service

and/or service procedures.

!

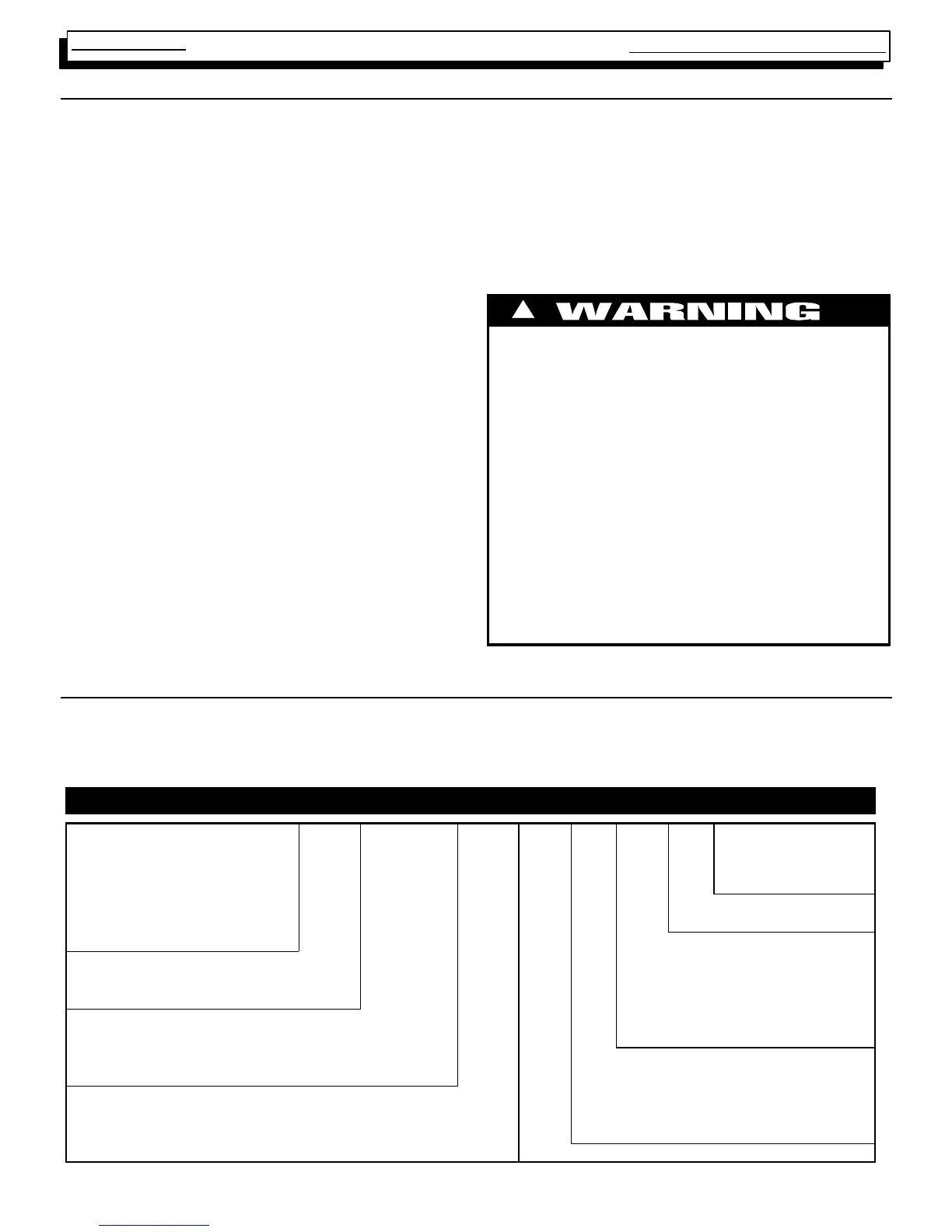

2. UNIT IDENTIFICATION

The unit’s rating plate contains important information for the

service technician. It also lists the complete Model Manufac-

turing and Serial Numbers.

These complete numbers are required to obtain correct re-

placement parts (example, in certain model families a unit

having a MARKET REVISION of “C” is likely to be equipped

with one or more different components.

MODEL NUMBER IDENTIFICATION GUIDE

* 9 MP T 075 B 12 A 1

Brand Identifier Engineering Rev.

T=Tempstar N=Neture Denotes minor changes

C = Comfortmaker/Keeprite Marketing Digit

H = Heil/Arcoaire X = Evaluation Denotes minor change

Cooling Airflow

Brand Identifier 08 = 800 CFM

8 = Non--Condensing, 80+% Gas Furnace 12 = 1200 CFM

9 = Condensing, 90+% Gas Furnace 14 = 1400 CFM

Installation Configuration 16 = 1600 CFM

UP = Upflow DN = Downflow UH = Upflow/Horizontal 20 = 2000 CFM

HZ = Horizontal DH = Downflow/Horizontal Cabinet Width

MP = Multiposition, Upflow/Downflow/Horizontal B = 15.5² Wide

Major Design Feature F = 19.1² Wide

1 = One (Single) Pipe L= Low NOx T = Two Stage J = 22.8² Wide

2 = Two Pipe N = Single Stage V = V ariable Speed L = 24.5² Wide

D = 1 or 2 Pipe P = PVC Vent Input (Nominal MBTUH)

Loading...

Loading...