Two- Stage Multi Position Furnace

Service

Manual

17

440 08 2002 02

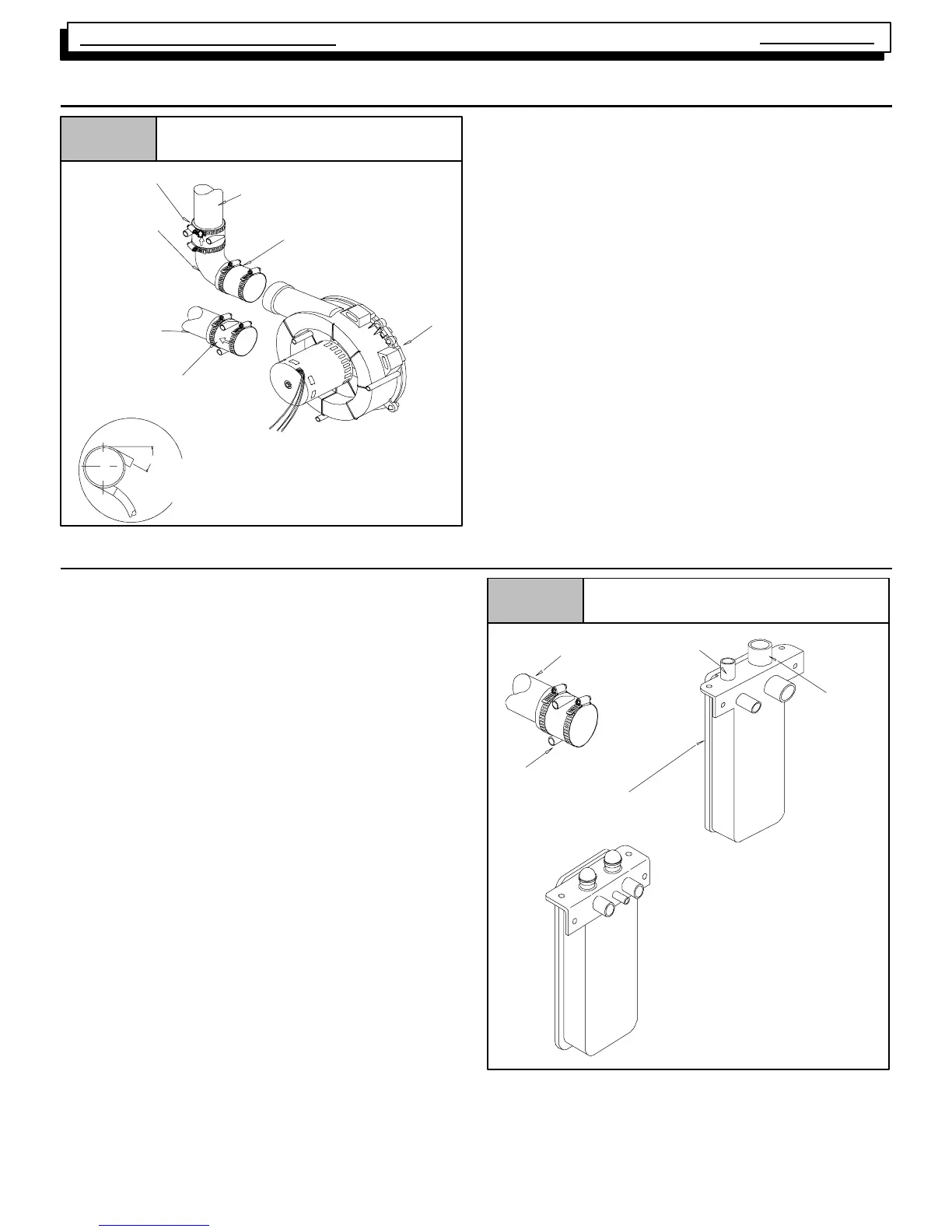

18. EXHAUST BLOWER

Figure 25

Exhaust Blower

Vent Pipe (Top panel exit)

Rubber Coupling & Clamps

90° Elbow

Blower

Vent Fitting

&Clamps

Vent Pipe

(Side panel exit)

Vent Fitting

&Clamps

25--23--35

DRAIN SIDE VIEW

C

L

Rotate

downward

20° to 30°

Always check the current “Technical Support Manual” for

part nos.

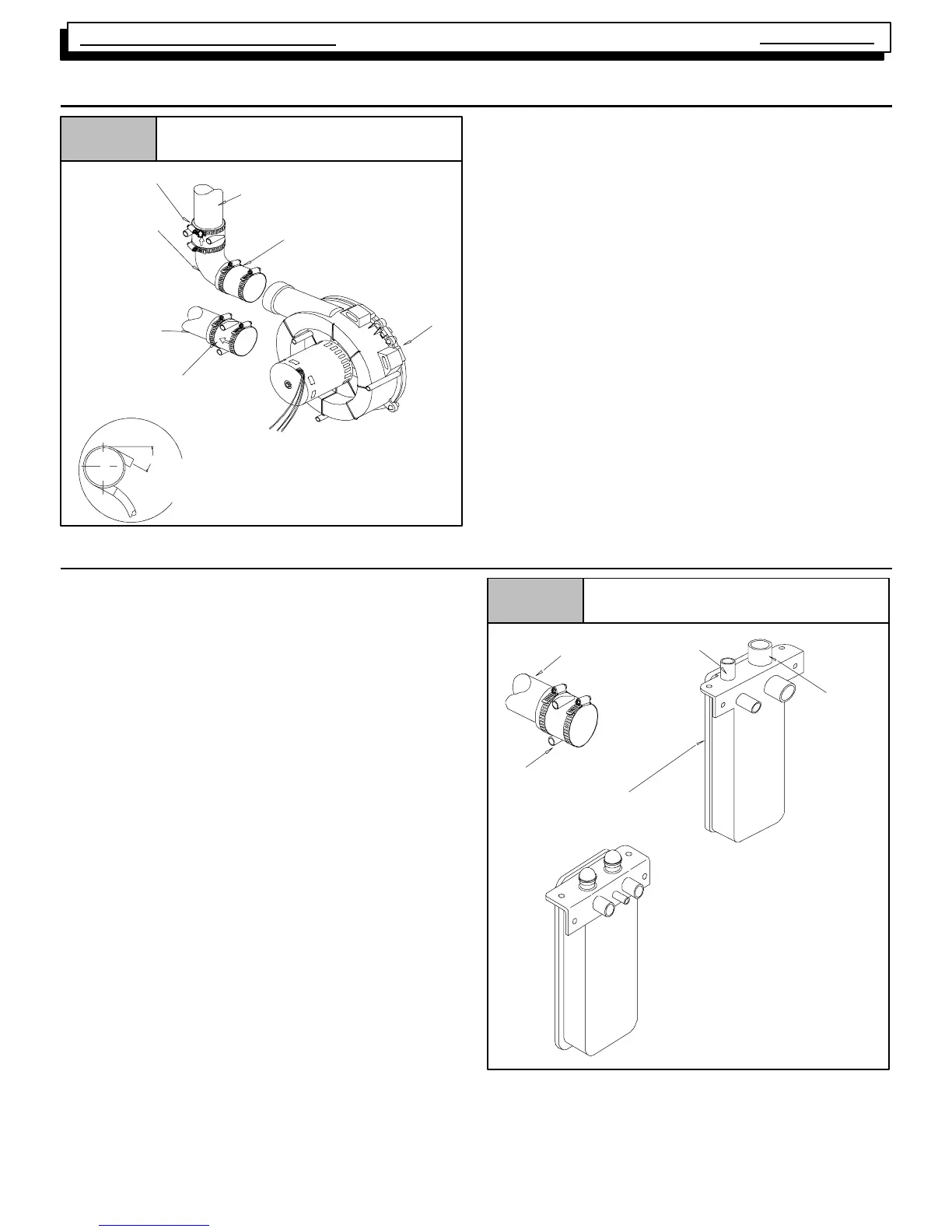

19. CONDENSATE DRAIN TRAP

This furnace removes both sensible and latent heat from the

products of combustion. Removal of the latent heat results in

condensation of the water vapor. The condensate is re-

moved from the furnace through the drains in the plastic tran-

sition and the vent fitting. The drains connect to the external-

ly mounted condensate drain trap on the left or right side of

the furnace. Refer to Figure 26.

The condensate drain trap supplied with the furnace MUST

be used. The drain line between the condensate drain trap

and the drain location must be constructed of

3

/

4

² PVC or

CPVC pipe.

The drain line must maintain a

1

/

4

² per foot downward slope

toward the drain.

DO NOT trap the drain line in any other location than at the

condensate drain trap supplied with the furnace.

If possible DO NOT route the drain line where it may freeze.

The drain line must terminate at an inside drain to prevent

freezing of the condensate and possible property damage.

1. A condensate sump pump MUST be used if required

by local codes, or if no indoor floor drain is available.

The condensate pump must be approved for use with

acidic condensate.

2. A plugged condensate drain line or a failed condensate

pump will allow condensate to spill. If the furnace is

installed where a condensate spill could cause dam-

age, it is recommended that an auxiliary safety switch

be installed to prevent operation of the equipment in

the event of pump failure or plugged drain line. If used,

an auxiliary safety switch should be installed in the R

circuit (low voltage) ONLY.

Figure 26 External Drain Trap

Vent Drain Connection

Drain Line

(hidden)

Transition

Box Drain

25--23-- 63

Vent Drain

Vent Pipe

(Side panel exit)

OLD

NEW

Loading...

Loading...