SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MVE

Specifications subject to change without notice.

8 440 04 4801 03

e. Measure time (in sec) for gas meter to complete 1

revolution and note reading. The 2 or 5 cubic feet dial

provides a more accurate measurement of gas flow.

f. Refer to Table 2 for cubic ft. of gas per hr.

g. Multiply gas rate cu ft./hr by heating value (Btuh/cu

ft.) to obtain input.

h. If clocked rate does not match required input from

Step 1, increase manifold pressure to increase input

or decrease manifold pressure to decrease input.

Repeat steps b through e until correct low−heat input

is achieved. Re−install low heat regulator seal cap on

gas valve.

i. Jumper R to W/W1, and W2. This keeps furnace

locked in high−heat operation when both W/W1 and

W2 are energized.

j. Repeat items (d) through (h) for high−heat operation,

repeating Step 2 and adjusting the high−heat regular

screw, as required.

4. Restore furnace to normal operating condition.

a. Turn gas valve On/Off switch to OFF.

b. Remove water column manometer or similar device

from manifold pressure tap.

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Manifold pressure tap set screw must be tightened or

1/8−in. NPT pipe plug must be installed to prevent gas

leaks.

!

WARNING

c. Tighten set screw on manifold tower pressure tap

with 3/32−in. hex wrench, or if 1/8−in. NPT plug was

removed, apply pipe dope sparingly to end of plug

and re−install in the gas valve.

d. Turn gas valve On/Off switch to ON.

e. Move setup SW1−2 on furnace control to position

required for attached thermostat (OFF for

single−stage thermostats, ON for two−stage

thermostats).

f. Check for gas leaks and verify furnace operation.

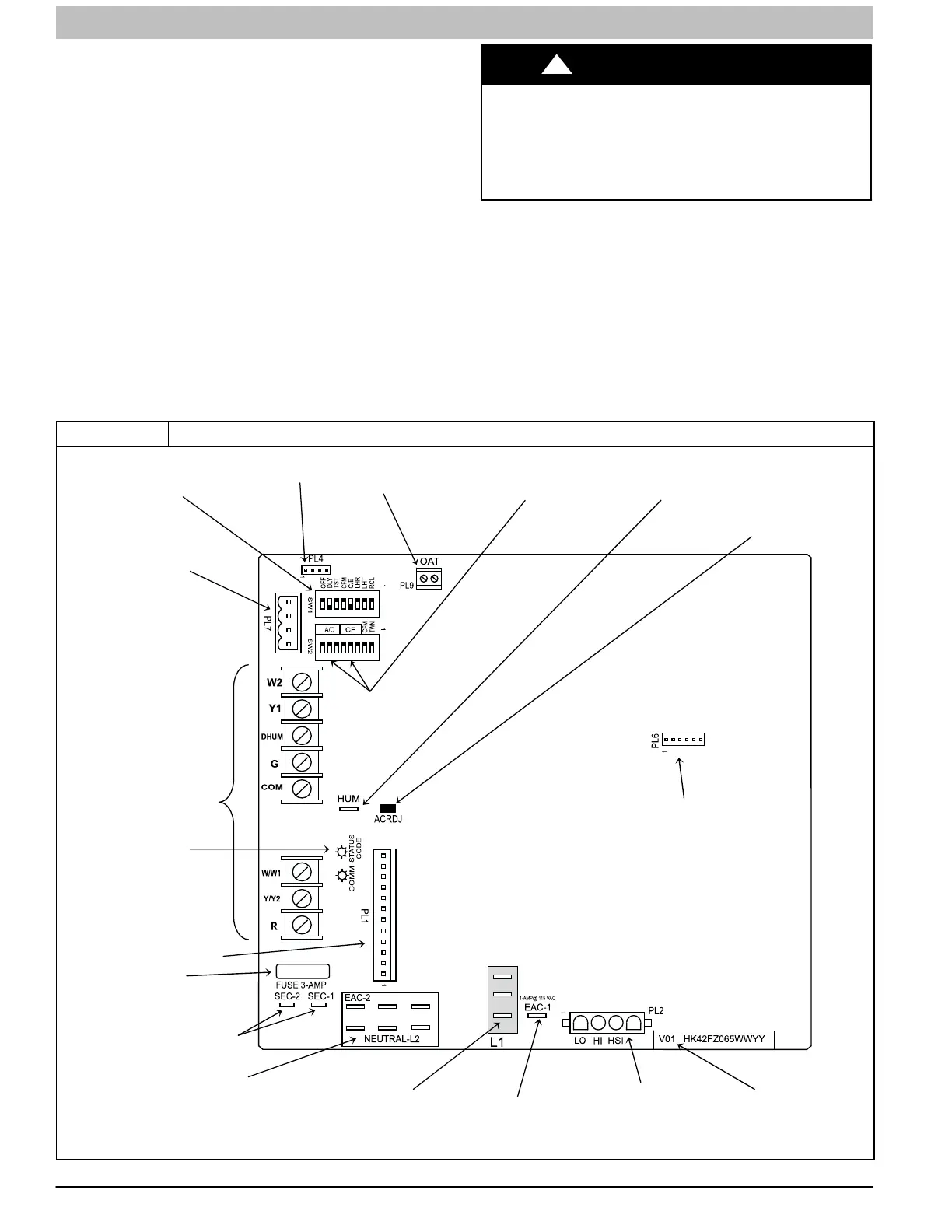

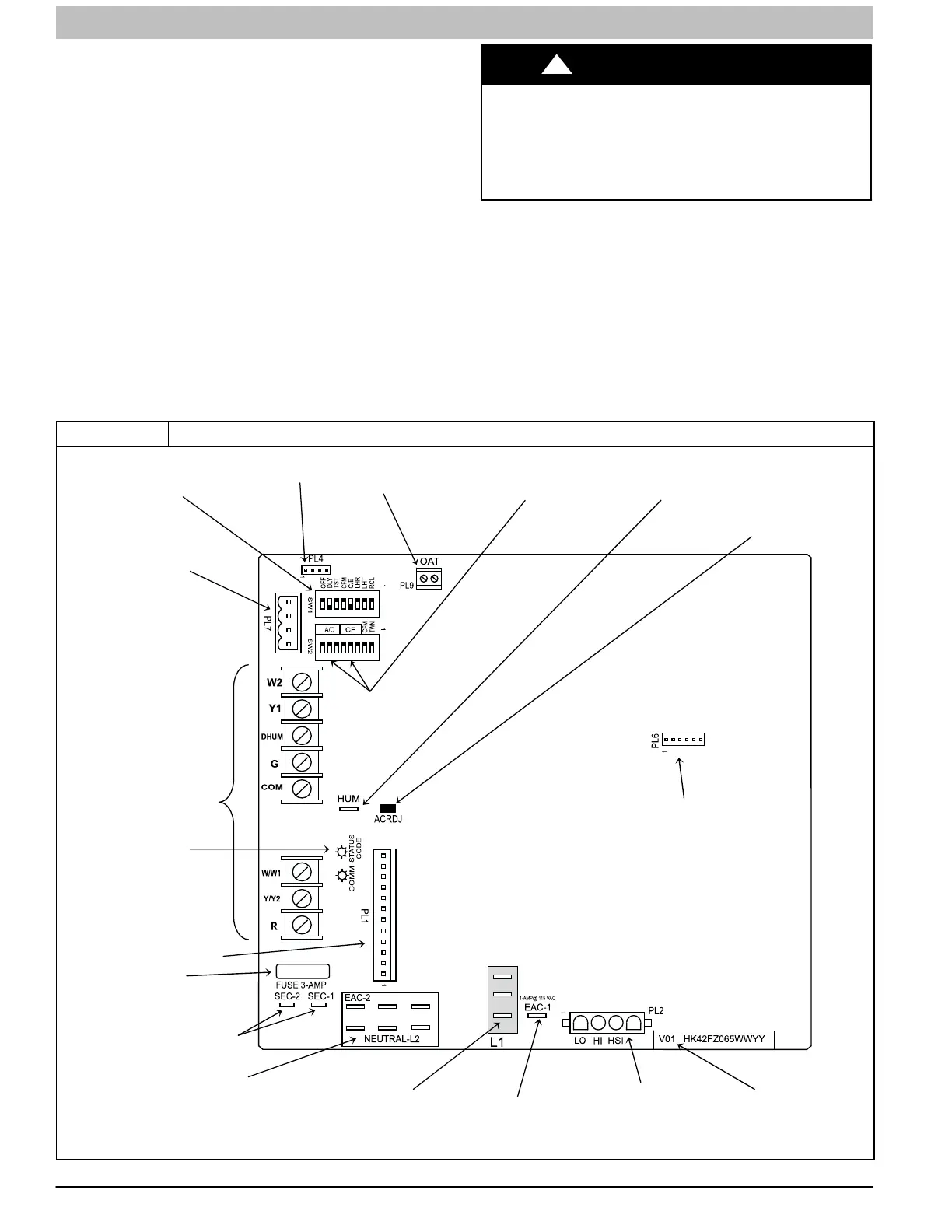

Figure 4 Example of Variable Speed Furnace Control for Variable Speed ECM Blower Motor

L14F003

24-V THERMOSTAT

TERMINALS

PL2 – HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTOR

115-VAC (L2) NEUTRAL

CONNECTIONS

115-VAC (L1) LINE

VOLTAGE CONNECTIONS

EAC-1 TERMINAL

115-VAC 1.0 AMP MAX.

PL1 – LOW VOLTAGE MAIN

HARNESS CONNECTOR

TRANSFORMER 24-VAC

CONNECTIONS

3-AMP FUSE

STATUS AND COMM

LED LIGHTS

SW1 SETUP

SWITCHES AND

BLOWER OFF-

DELAY

MODEL PLUG

CONNECTOR

COMMUNICATION

CONNECTOR

AIR CONDITIONING (A/C) &

CONTINUOUS FAN (CF)

AIRFLOW SETUP SWITCHES

OUTDOOR

AIR TEMP

CONNECTOR

HUMIDIFIER

TERMINAL (24-VAC

0.5 AMP MAX.)

ACRDJ – AIR

CONDITIONING

RELAY DISABLE

JUMPER

FLASH

UPGRADE

CONNECTOR

(FACTORY

ONLY)

SOFTWARE

VERSION

Loading...

Loading...