7

441 01 2611 06

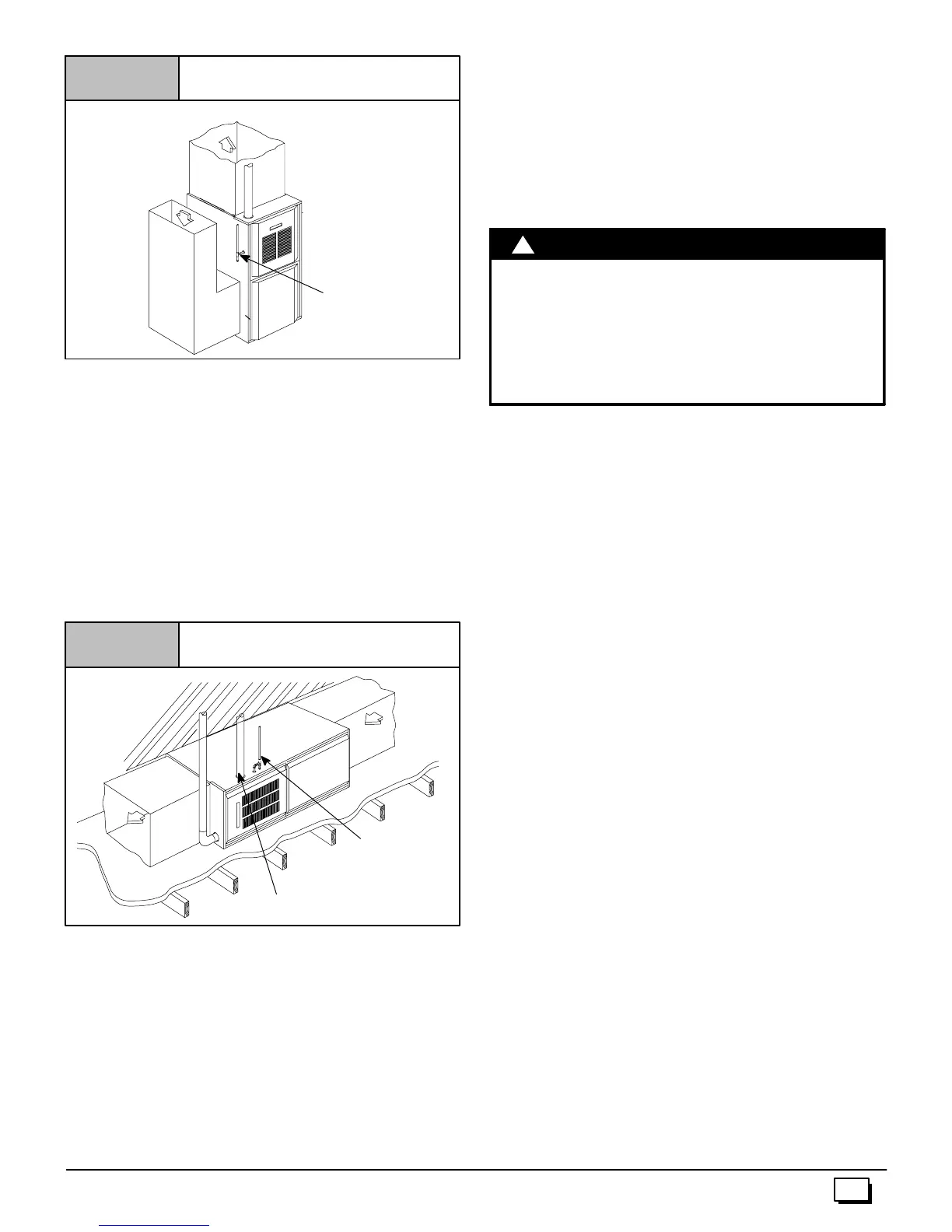

Typical Upflow Installation

Figure 3

25--23--17

VENT

SUPPLY

AIR

GAS SUPPLY

RETURN

AIR

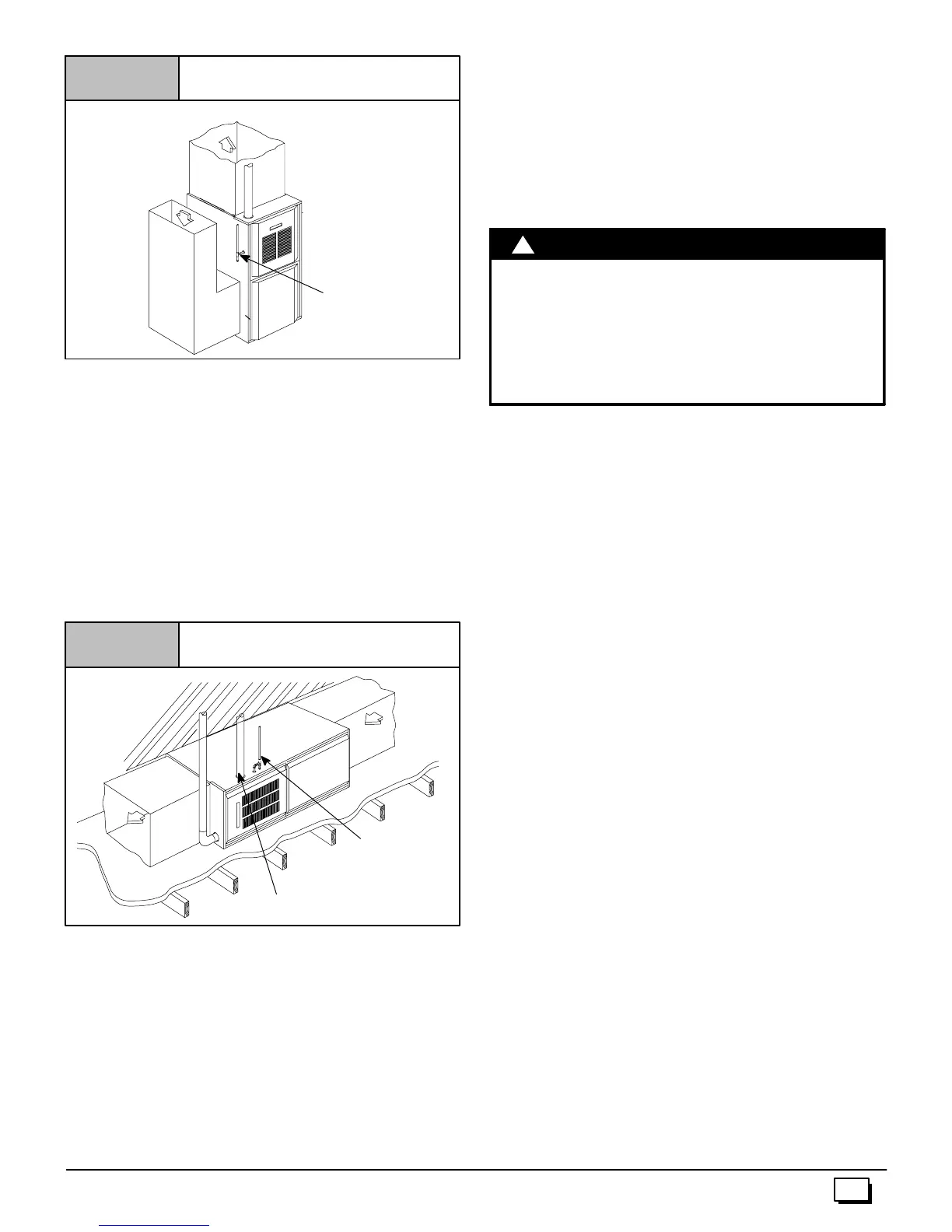

Horizontal

Ifyou purchaseda multi --position furnace,it can be installed hori-

zontallyin an attic, basement,crawlspace,alcove, or suspended

from a ceiling in a basement or utility room in either a right or left

airflow position. (see Figure 4)

Horizontally installed furnaces may be vented out the top of the

unitoroutthesidefacingup.See“Sideventing”forinstructionsto

rotate the vent to the side.

The minimum clearances to combustibles MUST be maintained

between the furnace and adjacent construction, as shown in

Figure 1 and Figure 2. ONLYthecornerofthecabinet is allowed

to contact the rafters as shown in Figure 4. All other clearances

MUST be observed as shown in Figure 1 and Figure 2.

Typical Horizontal Installation

Figure 4

VENT

VENT

GAS SUPPLY

SUPPLY

AIR

RETURN

AIR

25-23-18a

OPTIONAL

VENT LOCATION

Ifthefurnaceistobesuspendedfromthefloorjoistsinabasement

orcrawlspaceortheraftersinanattic,itis necessary to use s teel

pipe straps or an angle iron frame to attach the furnace. These

straps should be attached to the furnace bottom side with sheet

metal screws and to the rafters or joists with bolts. The preferred

methodistouse an angle ironframe bolted to therafters or joists.

Ifthefurnaceistobeinstalledatgroundlevelinacrawlspace,con-

sult local codes. A concrete pad 1² to 2² thick is recommended.

Thirtyinches(30²)isrequiredbetweenthefrontofthefurnaceand

adjacent construction or other appliances. This should be main-

tained for service clearance.

Keep all insulating materials clear from louvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

woodflooringorsupports, however,it is recommendedforfurther

fireprotectioncementboardor sheetmetalisplacedbetweenthe

furnace and the combustible wood floor and extend 12² beyond

the front of the furnace louver door. (This is a recommendation

only, not a requirement).

This furnace MUST NOT be installed directly on carpeting, tile or

other combustible material other than wood flooring or supports.

Downflow

FIRE HAZARD.

Failure to install unit on noncombustible subbase

couldresultin death,personalinjuryand/orproperty

damage.

Place furnace on noncombustible subbase on

downflow applications, unless installing on

noncombustible flooring.

!

W

RNING

If you purchased a Multi--position furnace (*8MP) it may be

installed in a downflow configuration, (see Figure 5). The mini-

mumclearancestocombustionconstructionMUSTbemaintained

between the furnace and adjacent construction, as shown in

Figure 1 and Figure 2.

In addition to clearances in Figure 1 and Figure 2, clearance for

the vent pipe must be considered.

As ubbaseforcombustiblefloorsMUSTbeusedwhenthefurnace

isinstalledasadownflowoncombustiblematerial. See11.“Duct-

work and Filter” (Downflow Section). The outlet flange must be

bent flat for downflow installation.

When installing a four--position furnace in the downflow position

(not the *8DNLfurnace),the logo is to be repositioned s o that it is

rightside--up as follows:

T8MPN/L

1. Find the door hardware k it that is stored in the furnace and

save it.

2. Carefullyremovelogofromtheoutsideofburnercompartment

door and save it.

3. Carefullyremovetwos mall plugbuttonsfromoutsideofblow-

er compartment door and save them.

4. Removetwo thumbscrews from blower c ompartment door by

cutting apart metal retainer washers on inside of door with

smalldiagonalcuttingpliers.Theretainer washerswillnotun-

screwfromthe thumbscrews.Savethetwo thumbscrewsand

two plastic washers.

5. Install two thumbscrews in holes at other end of blower

compartment door from where thumbscrews were removed.

a. A plastic washer should be on each of the two thumb-

screwsbeforeinsertingthe thumbscrewsintotheblower

compartment door holes.

b. After inserting each thumbscrew into the proper hole in

the blower door, push a new metal retainer washer onto

each thumbscrew as far as it will go.

6. Install newstrip of rubber gasketon inside of blowercompart-

ment door on edge that does not already have a gasket.

7. Installlogoretainerpinsintoholesinblowercompartmentdoor

from which plug buttons were removed.

8. Installplugbuttonsintoholesinburnercompartmentdoorfrom

which logo was removed.

9. Install blower compartment door on furnace with bevel edge

and logo at top.

Loading...

Loading...