NOTE:Stirthesolventcementfrequentlywhileusing.Useanatu-

ralbristlebrushorthedaubersuppliedwiththecement.Theprop-

er brush size is one inch.

2. After checking pipe and socket for proper fit, wipe socket

and pipe with cleaner-primer. Apply a liberal coat of primer

to inside surface of socket and outside of pipe. Do NOT al-

low primer to dry before applying cement.

3. Apply a thin coat of cement evenly in the socket. Quickly

apply a heavy coat of cement to the pipe end and insert

pipe into fittings with a slight twisting movement until it bot-

toms out.

NOTE: Cement MUST be fluid while inserting pipe. If NOT, recoat

pipe.

4. Hold the pipe in the fitting for 30 seconds to prevent the ta-

pered socket from pushing the pipe out of the fitting.

5. Wipe all excess cement from the joint with a rag. Allow 15

minutes before handling. Cure time varies according to fit,

temperature and humidity.

Connecting VentPipesand Termination

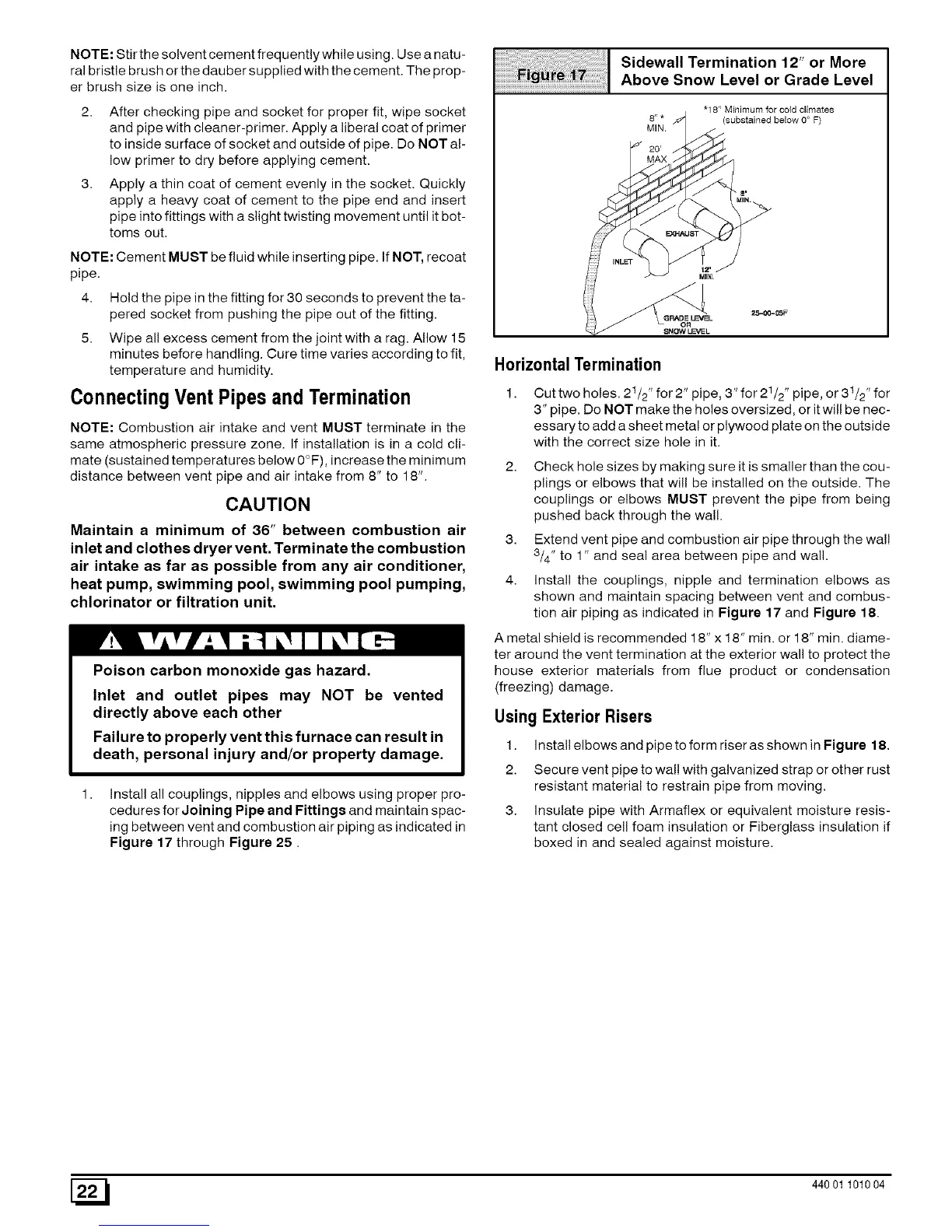

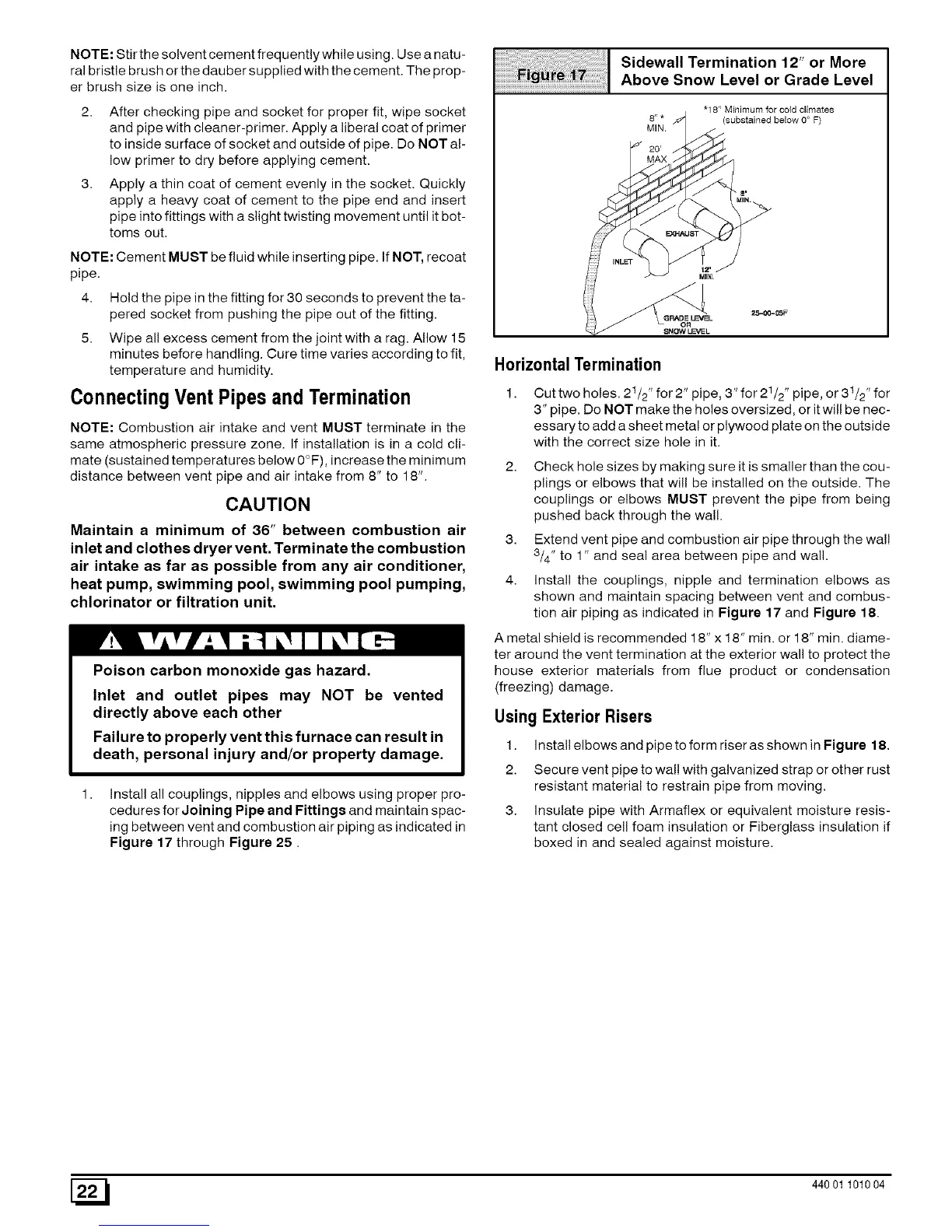

NOTE: Combustion air intake and vent MUST terminate in the

same atmospheric pressure zone. If installation is in a cold cli-

mate (sustained temperatures below 0°F), increase the minimum

distance between vent pipe and air intake from 8" to 18".

CAUTION

Maintain a minimum of 36" between combustion air

inlet and clothes dryer vent, Terminate the combustion

air intake as far as possible from any air conditioner,

heat pump, swimming pool, swimming pool pumping,

chlorinator or filtration unit.

Poison carbon monoxide gas hazard.

Inlet and outlet pipes may NOT be vented

directly above each other

Failure to properly vent this furnace can result in

death, personal injury and/or property damage.

Install all couplings, nipples and elbows using proper pro-

cedures for Joining Pipe and Fittings and maintain spac-

ing between vent and combustion air piping as indicated in

Figure 17 through Figure 25.

iiiiiiiiiiiiii_i;!i:ii:ii:ii!;i:;!ii!iiiiiililiiiii_!_:i_I!¸_i_i_i!_!_ii_ii_ii!_!ii_i_ii_ii_ii_ii_iiiiii_iii_ii_ii_ii_iiiiiiiiiiiiii_iiiiiiiii_iiiiiiiiiiiiiii_iii_iiiiiiiiiiii_i_!!!

Sidewall Termination 12" or More

.............................................................................Above Snow Level or Grade Level

"18" Minimum for cold climates

(substained below 0 ° F)

HorizontalTermination

Cut two holes. 21/2" for 2" pipe, 3" for 21/2" pipe, or 31/2" for

3" pipe. Do NOT make the holes oversized, or it will be nec-

essary to add a sheet metal or plywood plate on the outside

with the correct size hole in it.

2. Check hole sizes by making sure it is smaller than the cou-

plings or elbows that will be installed on the outside. The

couplings or elbows MUST prevent the pipe from being

pushed back through the wall.

3. Extend vent pipe and combustion air pipe through the wall

3/4" to 1" and seal area between pipe and wall.

4. install the couplings, nipple and termination elbows as

shown and maintain spacing between vent and combus-

tion air piping as indicated in Figure 17 and Figure 18.

A metal shield is recommended 18" x 18" min. or 18" min. diame-

ter around the vent termination at the exterior wall to protect the

house exterior materials from flue product or condensation

(freezing) damage.

Using Exterior Risers

1. InstallelbowsandpipetoformriserasshowninFigure 18.

2. Secure vent pipe to wall with galvanized strap or other rust

resistant material to restrain pipe from moving.

3. insulate pipe with Armaflex or equivalent moisture resis-

tant closed cell foam insulation or Fiberglass insulation if

boxed in and sealed against moisture.

[_ 440 01 101004

Loading...

Loading...