traponthefurnacemustbeprotectedfromfreezedamage.(See

Figure8troughFigure15)

1. Disconnectthe5/8"ODrubberhosefromtheventdrainfit-

tingthatislocateddownstreamofthecombustionblower.

Insertafunnelintothehoseandpourfour(4)ouncesof

sanitarytype(RV)antifreezeintothecondensatetrap.Re-

connectthe5/8"ODrubberhosetothestubonthevent

drainfitting.Securewiththehoseclamp.

2. Installation

2. Disconnect the 3/4" OD rubber hose from the condensate

trap. Insert a funnel into the hose and and pour four(4)

ounces of sanitary type (RV) antifreeze into the plastic

Transition box. Squeeze the hose together near the end

and quickly reconnect the 3/4" OD rubber hose to the stub

on the condensate trap. Secure with the hose clamp.

When you return home, your furnace will be ready to start, as it is

not necessary to drain the antifreeze from the furnace.

Poison carbon monoxide gas Hazard.

This furnace can NOT be common vented or

connected to any type B, BW or L vent or vent

connector, nor to any portion of a factory-built or

masonry chimney. If this furnace is replacing a

previously common-vented furnace, it may be

necessary to resize the existing vent and

chimney to prevent oversizing problems for the

other remaining appliance(s). See Venting and

Combustion Air Check in Gas Vent Installation

section. This furnace MUST be vented to the

outside.

Failure to properly vent this furnace or other

appliances can result in death, personal injury

and/or property damage.

LocationandClearances

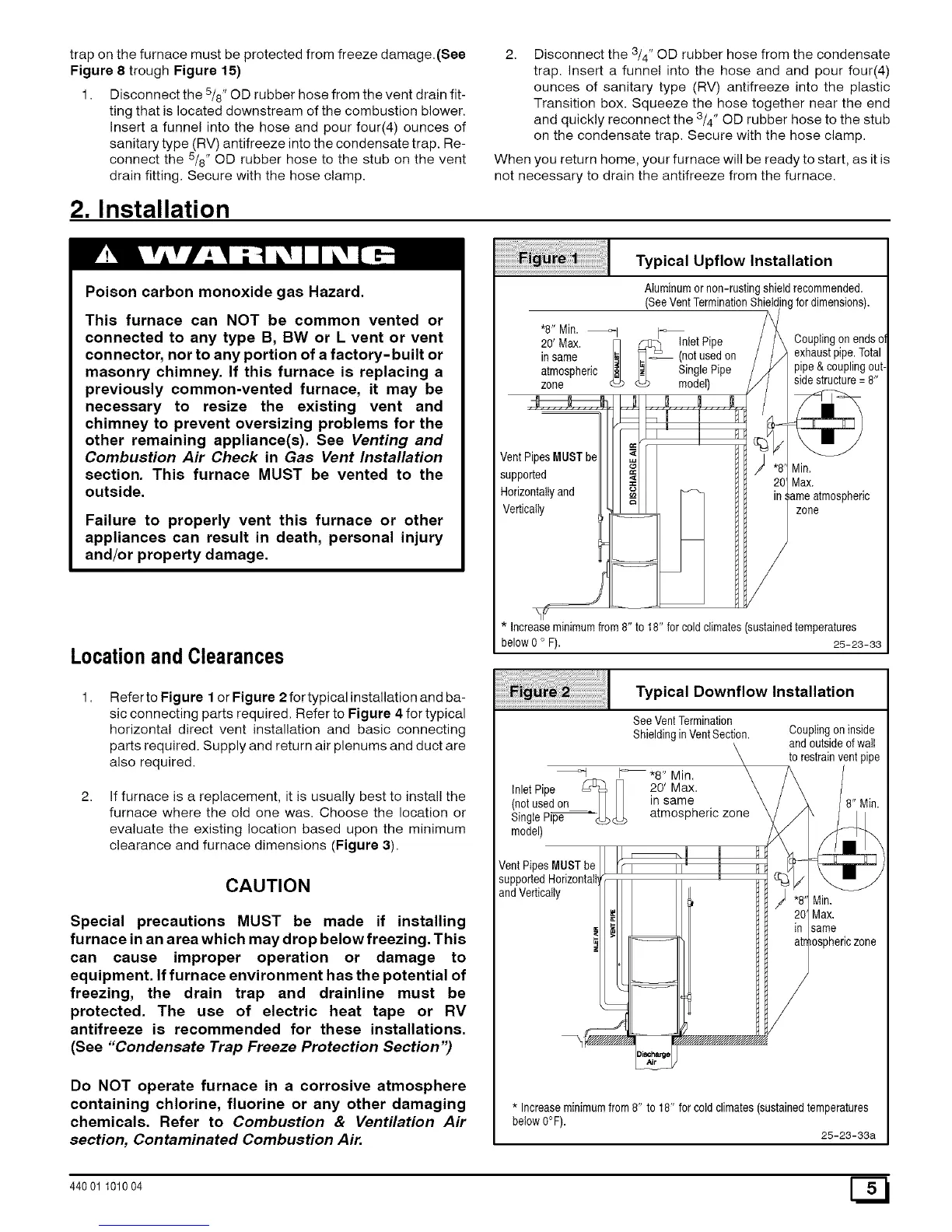

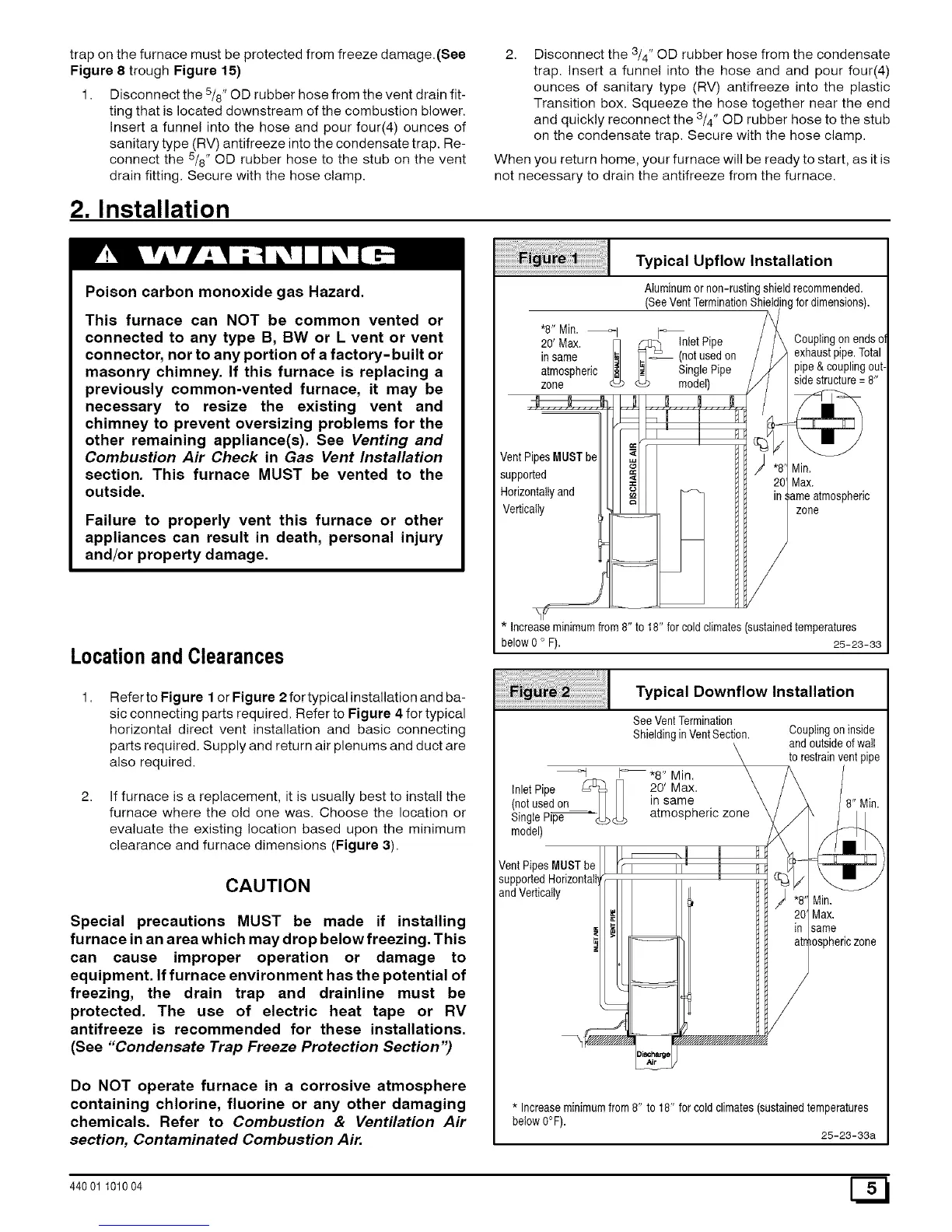

Refer to Figure 1 or Figure 2 for typical installation and ba-

sic connecting parts required. Refer to Figure 4 for typical

horizontal direct vent installation and basic connecting

parts required. Supply and return air plenums and duct are

also required.

If furnace is a replacement, it is usually best to install the

furnace where the old one was. Choose the location or

evaluate the existing location based upon the minimum

clearance and furnace dimensions (Figure 3).

CAUTION

Special precautions MUST be made if installing

furnace in an area which may drop below freezing. This

can cause improper operation or damage to

equipment. If furnace environment has the potential of

freezing, the drain trap and drainline must be

protected. The use of electric heat tape or RV

antifreeze is recommended for these installations.

(See "Condensate Trap Freeze Protection Section")

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or any other damaging

chemicals. Refer to Combustion & Ventilation Air

section, Contaminated Combustion Air.

Typical Upflow Installation

AIuminumornon-rustingshietdrecommended.

(SeeVentTerminationShieldingfordimensions).

•8" Min. _ I_

20' Max. rq _ InletPipe Ooup%gonendsoi

in same <_ (_ _-_ (notusedon exhaustpipe.Total

atmospheric Single Pipe pipe& couplingout-

zone model) sidestructure= 8"

VentPipes MUSTbe

supported

Horizontallyand

Vertically

Min.

Max.

zone

* Increaseminimumfrom8" to 18" forcold climates (sustainedtemperatures

below0 o F). 25-23-33

Typical Downflow Installation

SeeVentTermination

ShieldinginVentSection.

I_ "8" Min.

Inlet Pipe _ _] 20' Max.

(notusedon_H in same

single pip-_(_ c_) atmospheric zone

model)

Vent PipesMUSTb

supportedHorizonta

and Vertically

\_ _ "////_/////////Y////_

Couplingoninside

and outsideofwait

torestrainventpipe

Min.

Max.

same

* Increaseminimumfrom8" to 18" for coldclimates(sustainedtemperatures

below0°F).

25-23-33a

440 01 101004

Loading...

Loading...