2. Gas input to burners MUST NOT exceed the rated input

shown on rating plate.

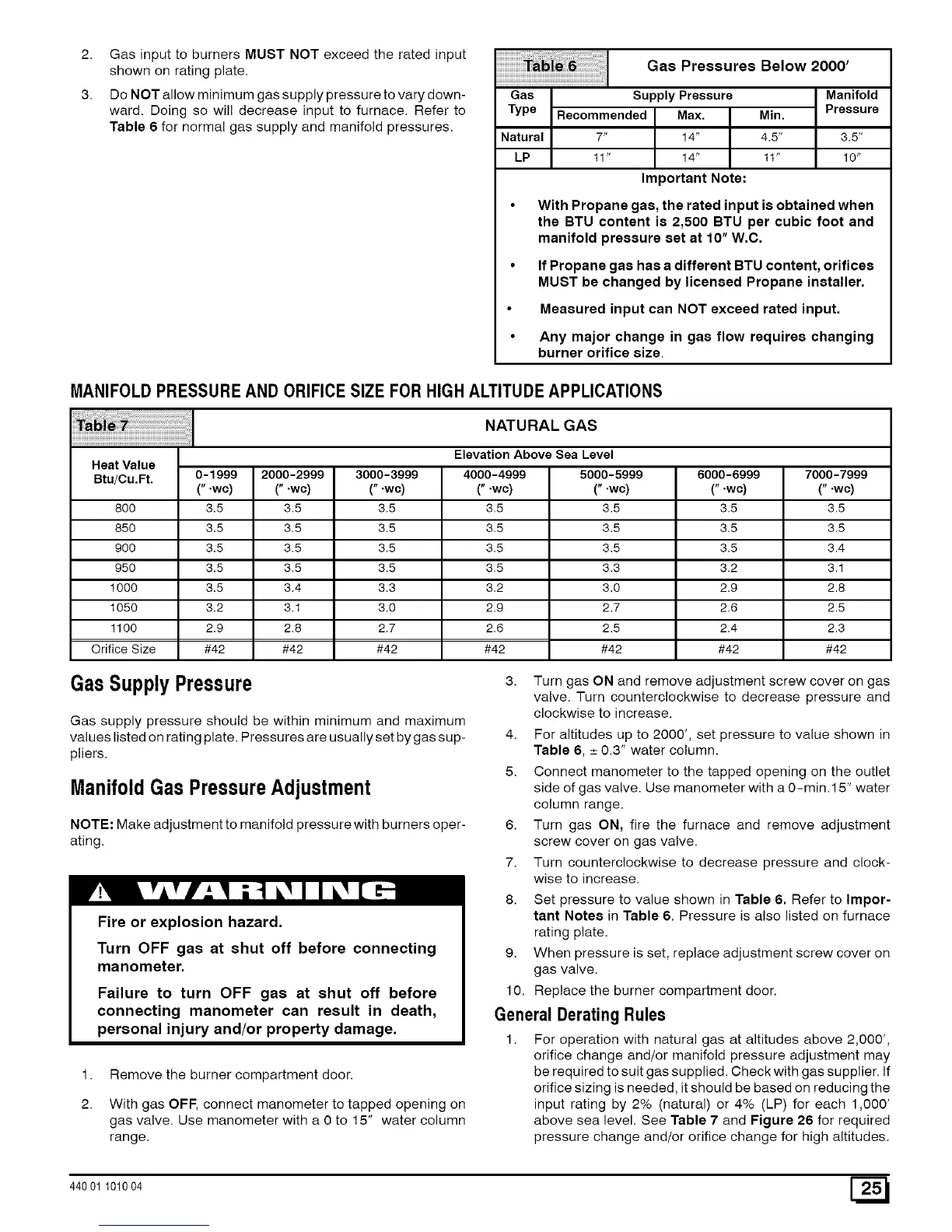

3. Do NOT allow minimum gas supply pressure to vary down-

ward. Doing so will decrease input to furnace. Refer to

Table 6 for normal gas supply and manifold pressures.

Gas

Type

Natural

LP

Gas Pressures Below 2000'

Supply Pressure

Recommended Max.

7" 14"

11" 14"

Important Note:

Manifold

Min. Pressure

4.5" 3.5"

11" 10"

With Propane gas, the rated input is obtained when

the BTU content is 2,500 BTU per cubic foot and

manifold pressure set at 10" W.C.

If Propane gas has a different BTU content, orifices

MUST be changed by licensed Propane installer.

Measured input can NOT exceed rated input.

Any major change in gas flow requires changing

burner orifice size.

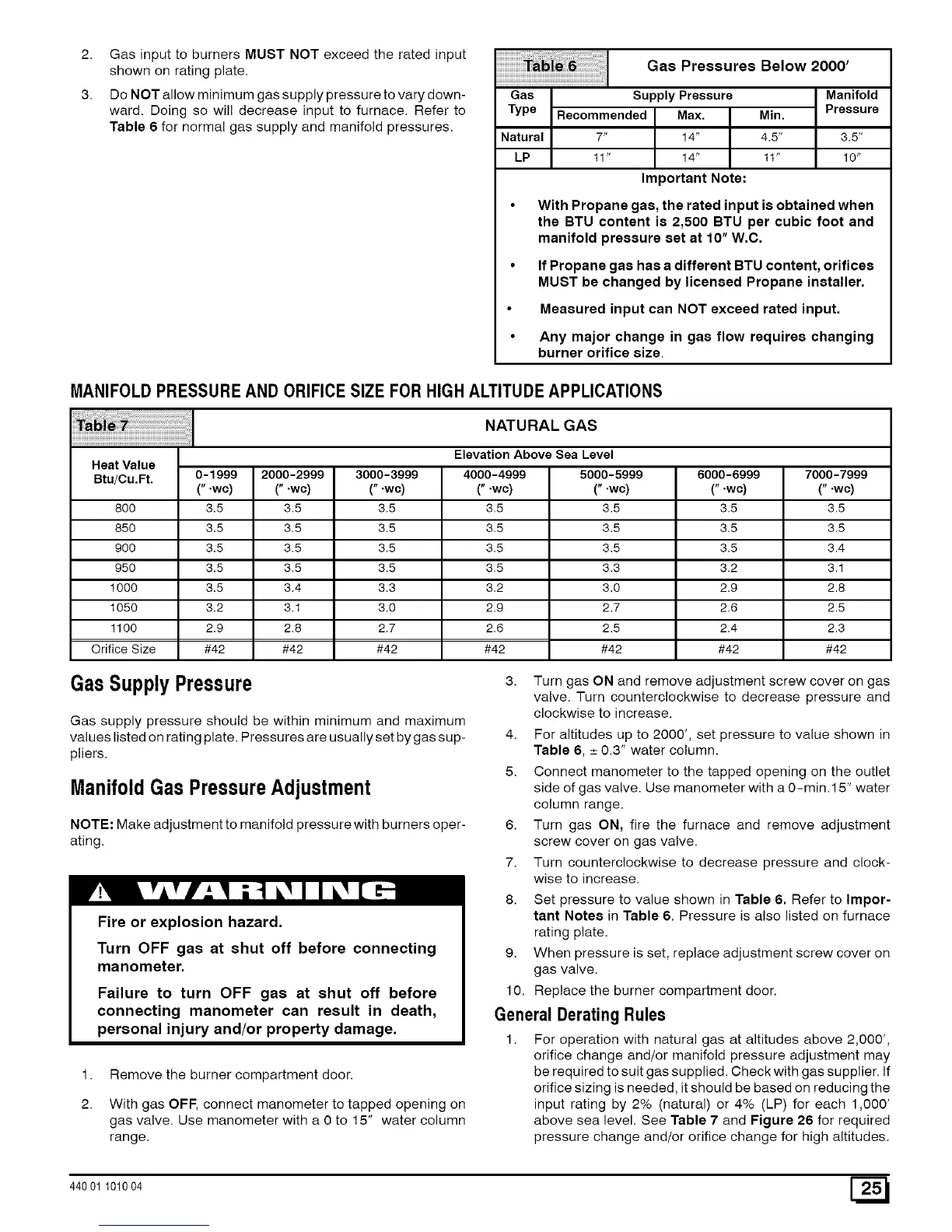

MANIFOLDPRESSURE AND ORIFICE SIZE FOR HIGH ALTITUDEAPPLICATIONS

..... i

i_Tai_!_i_!_i_!i_!ii!_iii!_i! NATURALGAS

Elevation Above Sea Level

Heat Value

Btu/Cu.Ft. 0-1999 2000-2999 3000-3999 4000-4999 5000-5999 6000-6999 7000-7999

(" .wc) (" .wc) (".wc) (".wc) (".wc) (".wc) (" .wc)

800 3.5 3.5 3.5 3.5 3.5 3.5 3.5

850 3.5 3.5 3.5 3.5 3.5 3.5 3.5

900 3.5 3.5 3.5 3.5 3.5 3.5 3.4

950 3.5 3.5 3.5 3.5 3.3 3.2 3.1

1000 3.5 3.4 3.3 3.2 3.0 2.9 2.8

1050 3.2 3.1 3.0 2.9 2.7 2.6 2.5

1100 2.9 2.8 2.7 2.6 2.5 2.4 2.3

Orifice Size #42 #42 #42 #42 #42 #42 #42

GasSupply Pressure

Gas supply pressure should be within minimum and maximum

values listed on rating plate. Pressures are usually set by gas sup-

pliers.

ManifoldGas PressureAdjustment

NOTE: Make adjustment to manifold pressure with burners oper-

ating.

Fire or explosion hazard.

Turn OFF gas at shut off before connecting

manometer.

Failure to turn OFF gas at shut off before

connecting manometer can result in death,

personal injury and/or property damage.

1.

2.

Remove the burner compartment door.

With gas OFF, connect manometer to tapped opening on

gas valve. Use manometer with a 0 to 15" water column

range.

3. Turn gas ON and remove adjustment screw cover on gas

valve. Turn counterclockwise to decrease pressure and

clockwise to increase.

4. For altitudes up to 2000', set pressure to value shown in

Table 6, ± 0.3" water column.

5. Connect manometer to the tapped opening on the outlet

side of gas valve. Use manometer with a 0-rain.15" water

column range.

6. Turn gas ON, fire the furnace and remove adjustment

screw cover on gas valve.

7. Turn counterclockwise to decrease pressure and clock-

wise to increase.

8. Set pressure to value shown in Table 6. Refer to Impor-

tant Note8 in Table 6. Pressure is also listed on furnace

rating plate.

9. When pressure is set, replace adjustment screw cover on

gas valve.

10. Replace the burner compartment door.

General DeraUngRules

1. For operation with natural gas at altitudes above 2,000',

orifice change and/or manifold pressure adjustment may

be required to suit gas supplied. Check with gas supplier. If

orifice sizing is needed, it should be based on reducing the

input rating by 2% (natural) or 4% (LP) for each 1,000'

above sea level. See Table 7 and Figure 26 for required

pressure change and/or orifice change for high altitudes.

44001 101004 [_

Loading...

Loading...