Example

Natural Gas No.of Seconds | TimePer Cubic BTUPer

BTUContent Per Hour t Footin Seconds Hour1,000 3,600 48 75,000

1,000 x 3,600 + 48 = 75,000 BTUH

3. Time how many seconds it takes the smallest dial on the

gas meter to make one complete revolution. Refer to Ex-

ample.

4. Relight all appliances and ensure all pilots are operating.

NOTE: If meter uses a 2 cubic foot dial, divide results (seconds)

by two.

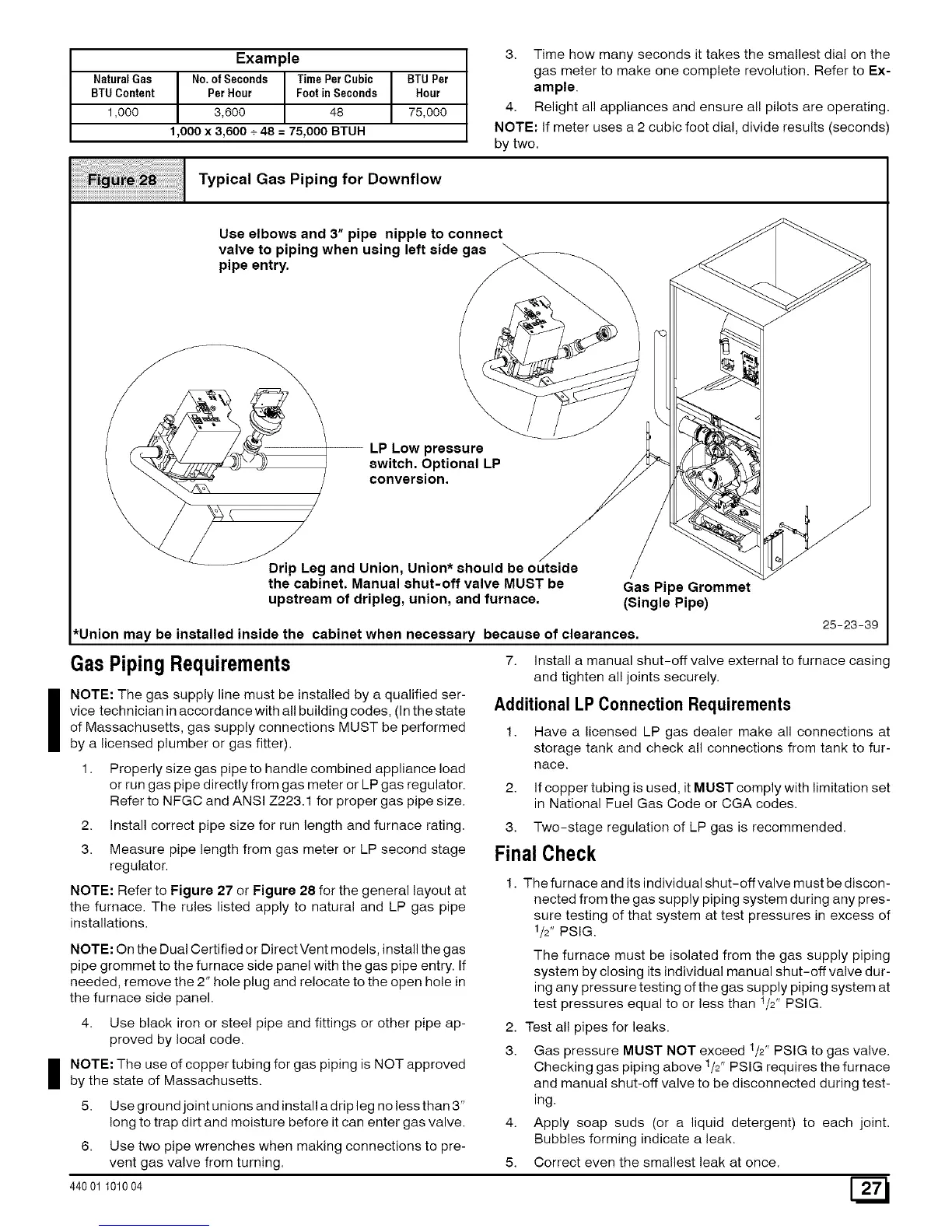

Typical Gas Piping for Downflow

Use elbows and 3" pipe nipple to connect

valve to piping when using left side gas

pipe entry.

LP Low pressure

switch. Optional LP

conversion.

Drip Leg and Union, Union* should be outside

the cabinet. Manual shut-off valve MUST be

upstream of dripleg, union, and furnace.

Gas Pipe Grommet

(Single Pipe)

*Union may be installed inside the cabinet when necessary because of clearances.

Gas Piping Requirements

NOTE: The gas supply line must be installed by a qualified ser-

vice technician in accordance with all building codes, (In the state

of Massachusetts, gas supply connections MUST be performed 1.

by a licensed plumber or gas fitter).

1. Properly size gas pipe to handle combined appliance load

or run gas pipe directly from gas meter or LP gas regulator. 2.

Refer to NFGC and ANSI Z223.1 for proper gas pipe size.

2. Install correct pipe size for run length and furnace rating.

3. Measure pipe length from gas meter or LP second stage

regulator.

NOTE: Refer to Figure 27 or Figure 28 for the general layout at

the furnace. The rules listed apply to natural and LP gas pipe

installations.

NOTE: On the Dual Certified or Direct Vent models, install the gas

pipe grommet to the furnace side panel with the gas pipe entry. If

needed, remove the 2" hole plug and relocate to the open hole in

the furnace side panel.

4. Use black iron or steel pipe and fittings or other pipe ap-

proved by local code.

I OTE: The use of copper tubing for gas piping is NOT approved

by the state of Massachusetts.

5. Use ground joint unions and install a drip leg no less than 3"

long to trap dirt and moisture before it can enter gas valve. 4.

6. Use two pipe wrenches when making connections to pre-

vent gas valve from turning. 5.

440 01 101004

25-23-39

7. Install a manual shut-off valve external to furnace casing

and tighten all joints securely.

Additional LP Connection Requirements

Have a licensed LP gas dealer make all connections at

storage tank and check all connections from tank to fur-

nace.

If copper tubing is used, it MUST comply with limitation set

in National Fuel Gas Code or CGA codes.

3. Two-stage regulation of LP gas is recommended.

FinalCheck

1. The furnace and its individual shut-off valve must be discon-

nected from the gas supply piping system during any pres-

sure testing of that system at test pressures in excess of

1/2" PSlG.

The furnace must be isolated from the gas supply piping

system by closing its individual manual shut-off valve dur-

ing any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2" PSlG.

2. Test all pipes for leaks.

3. Gas pressure MUST NOT exceed t/2" PSIG to gas valve,

Checking gas piping above t/2" PSIG requires the furnace

and manual shut-off valve to be disconnected during test-

ing.

Apply soap suds (or a liquid detergent) to each joint,

Bubbles forming indicate a leak.

Correct even the smallest leak at once.

Loading...

Loading...