REDUCED EQUIPMENT LIFE HAZARD

Failure to follow these precautions could result in

damage to the unit being installed.

1) Make all electrical connections in accordance with

National Electric code (NEC) NFPa 70 and local electrical

codes governing such wiring. In Canada, all electrical

connections must be in accordance with CSA standard

C22.1, Canadian Electrical Code Part 1, and applicable

local codes. Refer to unit wiring diagram.

2) Use only copper conductor for connections

between field-supplied electrical disconnect switch and

unit. DO NOT USE ALUMINUM WIRE.

3) Be sure that high-voltage power to unit is within

operating voltage range indicated on unit rating plate.

4) Do not damage internal components when drilling

through any panel to mount electrical hardware,

conduit, etc. Consult local power company for

correction of improper voltage and/or phase imbalance.

Disconnect Switch

The unit must have separate electrical service with a

field-supplied, waterproof, disconnect switch mounted at,

or within sight from, the unit. Refer tothe unit rating plate for

maximum fuse/circuit breaker size and minimum circuit

amps (ampacity) for wire sizing.

Ground Connections

Do NOT complete line voltage connections until unit is

permanently grounded. All line voltage connections and the

ground connection MUST be made with copper wire.

A ground lug is installed in the control box area for the

ground connection. Use a copper conductor of the

appropriate size from the unit to a grounded connection in

the electrical service panel or a properly driven and

electrically grounded ground rod. See warning above.

Line Voltage Wiring - (Wiring Diagrams page 12 & 13)

Connections for line voltage are made in the unit control box

area. Refer to wiring diagram located on the Access panel.

For access, remove the burner access panel.

1. Run the high voltage (L1, L2) and ground leads into the

control box.

2. Connect ground lead to chassis ground connection.

3. Connect L1 to pressure lug connection 11 of the

compressor contactor.

4. Connect L2 to pressure lug connection 23 of the

compressor contactor.

Thermostat / Low Voltage Wiring

Location of the thermostat has an important effect on home

comfort. FOLLOW THE THERMOSTAT INSTRUCTION

MANUAL FOR CORRECT LOCATION, MOUNTING, AND

WIRING.

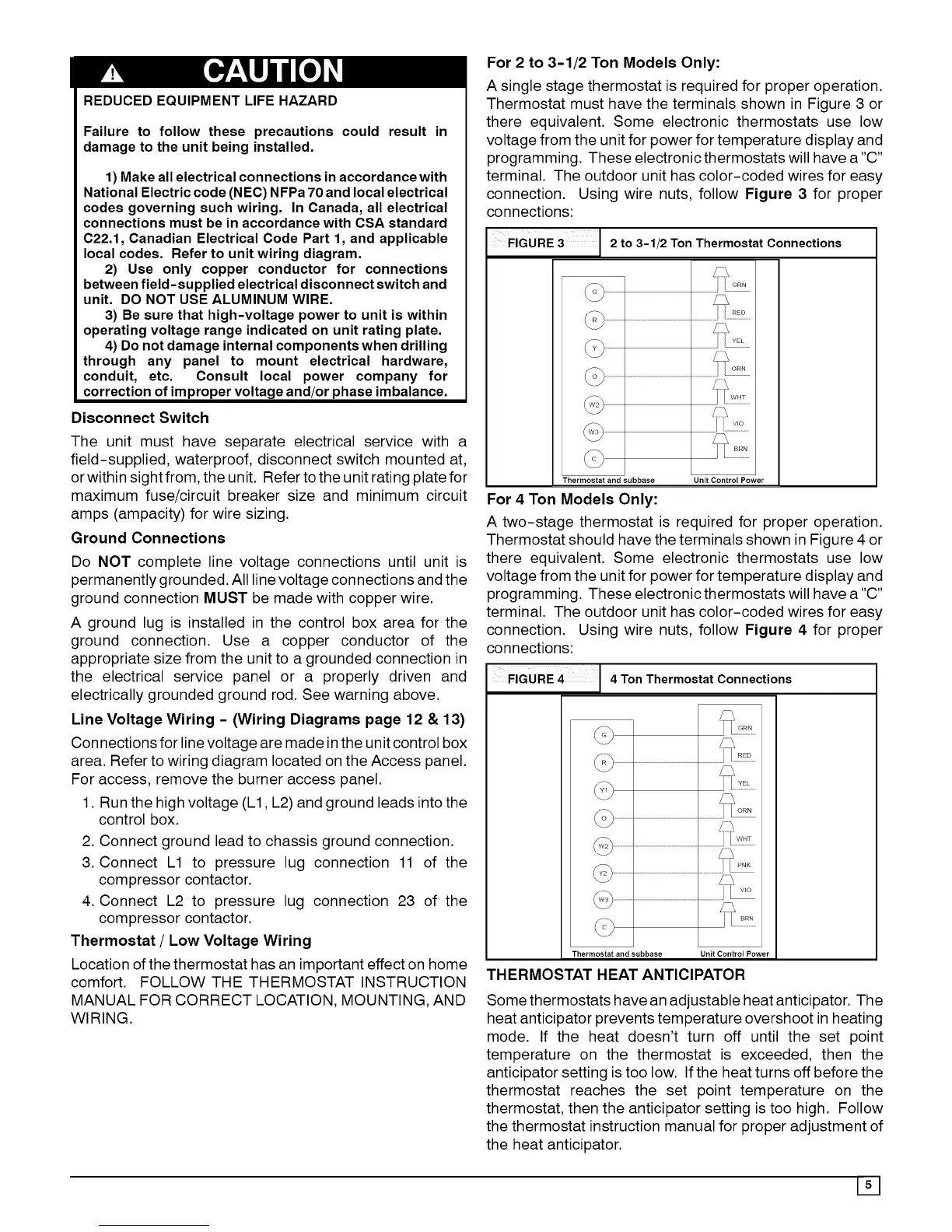

For 2 to 3-1/2 Ton Models Only:

A single stage thermostat is required for proper operation.

Thermostat must have the terminals shown in Figure 3 or

there equivalent. Some electronic thermostats use low

voltage from the unit for power for temperature display and

programming. These electronic thermostats will have a "C"

terminal. The outdoor unit has color-coded wires for easy

connection. Using wire nuts, follow Figure 3 for proper

connections:

FIGURE 3 2 to 3-1/2 Ton Thermostat Connections

Thermostat and subbase Unit Control Power

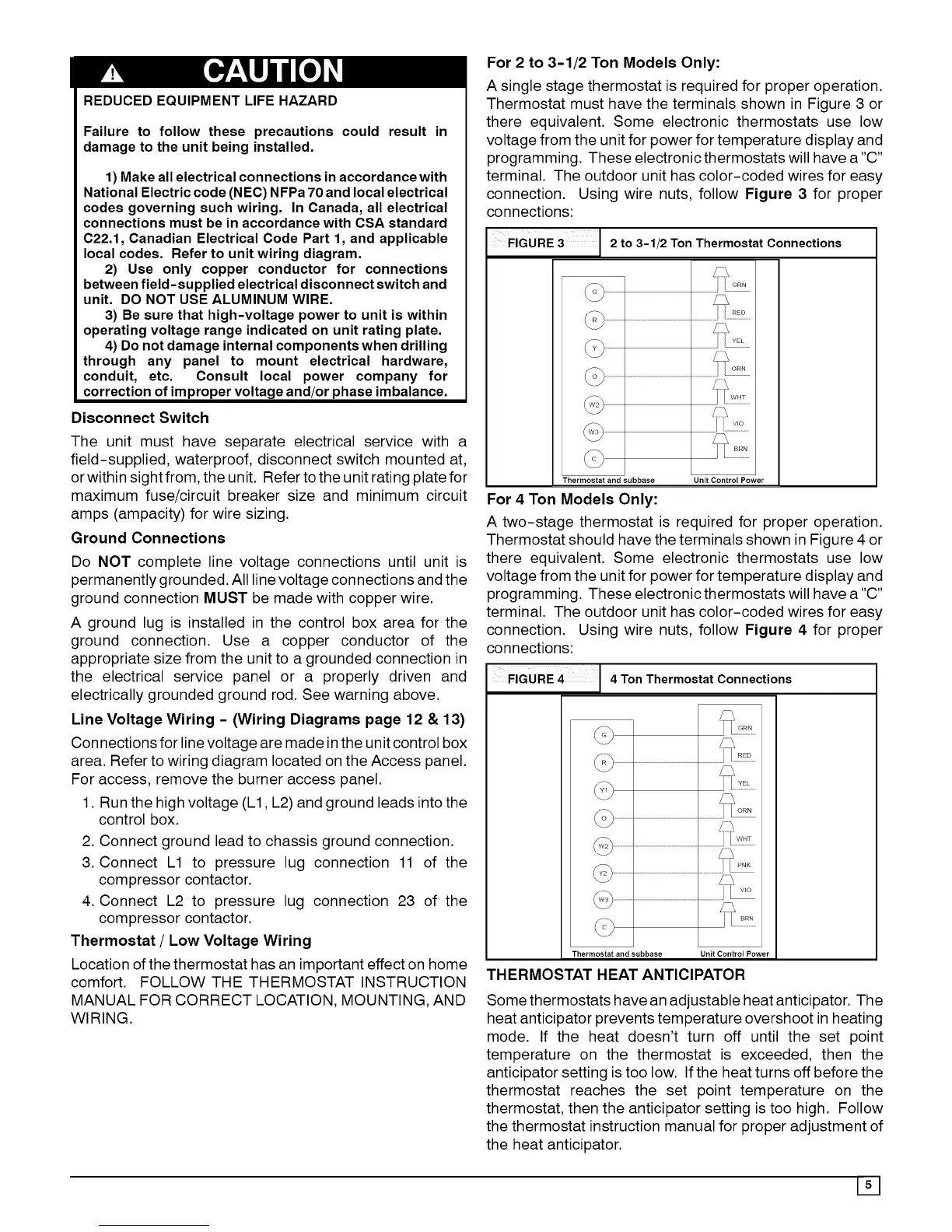

For 4 Ton Models Only:

A two-stage thermostat is required for proper operation.

Thermostat should have the terminals shown in Figure 4 or

there equivalent. Some electronic thermostats use low

voltage from the unit for power for temperature display and

programming. These electronic thermostats will have a "C"

terminal. The outdoor unit has color-coded wires for easy

connection. Using wire nuts, follow Figure 4 for proper

connections:

FIGURE 4 4 Ton Thermostat Connections

Thermostat and subbase Unit Control Power

THERMOSTAT HEAT ANTICIPATOR

Some thermostats have an adjustable heat anticipator. The

heat anticipator prevents temperature overshoot in heating

mode. If the heat doesn't turn off until the set point

temperature on the thermostat is exceeded, then the

anticipator setting istoo low. If the heat turns off before the

thermostat reaches the set point temperature on the

thermostat, then the anticipator setting is too high. Follow

the thermostat instruction manual for proper adjustment of

the heat anticipator.

Loading...

Loading...