6. AIRFLOW ADJUSTMENT

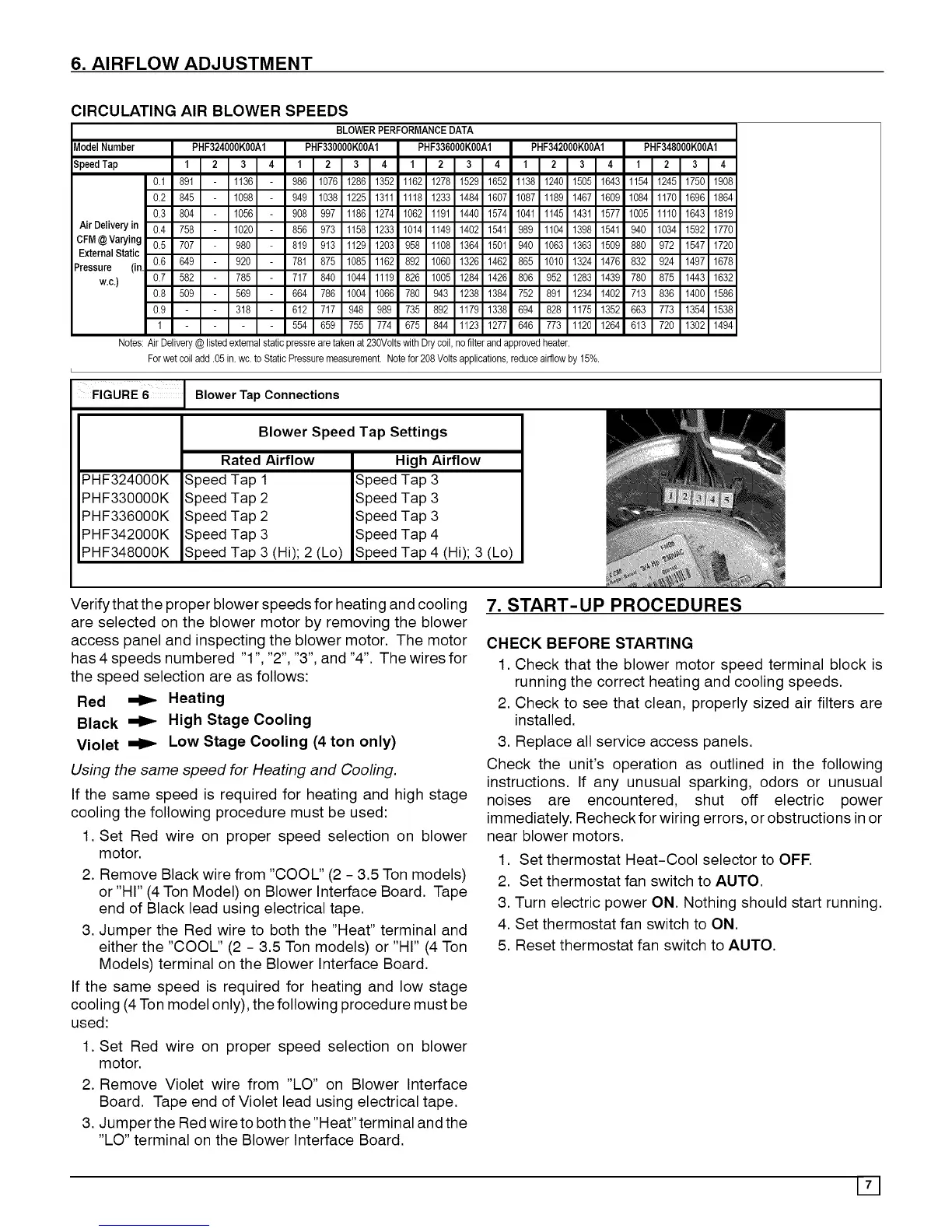

CIRCULATING AIR BLOWER SPEEDS

BLOWERPERFORMANCEDATA

AirDeliveryin

CFM@ Varying

ExternalStatic

Pressure (in,

W.C.)

_odel Number PHF324000K00AI PHF330000K00AI

3peedTap 1 2 3 4 1 2 3 4

0.1 891 1136 986 1076 1286 1352

0.2 845 1098 949 1038 1225 1311

0.3 804 1056 908 997 1186 1274

0.4 758 1020 856 973 1158 1233

0.5 707 980 819 913 1129 1203

0.6 649 920 781 875 1085 1162

0.7 582 785 717 840 1044 1119

0.8 509 569 664 786 1004 1066

0.9 318 612 717 948 989

1 554 659 755 774

PHF336000K00A1

1 2 3 4

1162 1278 1529 1652

1118 1233 1484 1607

1062 1191 1440 1574

1014 1149 1402 1541

958 1108 1364 1501

892 1060 1326 1462

826 1005 1284 1426

780 943 1238 1384

735 892 1179 1338

675 844 1123 1277

PHF342000K00A1 PHF348000K00A1

1 2 3 4 1 2 3 4

1138 1240 1505 1643 1154 1245 1750 1908

1087 1189 1467 1609 1084 1170 1696 1864

1041 1145 1431 1577 1005 1110 1643 1819

989 1104 1398 1541 940 1034 1592 1770

940 1063 1363 1509 880 972 1547 1720

865 1010 1324 1476 832 924 1497 1678

806 952 1283 1439 780 875 1443 1632

752 891 1234 1402 713 836 1400 1586

694 828 1175 1352 663 773 1354 1538

646 773 1120 1264 613 720 1302 1494

Notes:Air Delivery@listed externalstatic pressrearetaken at230Voltswith Drycoil, no filterand approvedheater.

Forwet coiladd .05in. wc. to Static Pressuremeasurement.Notefor 208Volts applications,reduceairflowby15%.

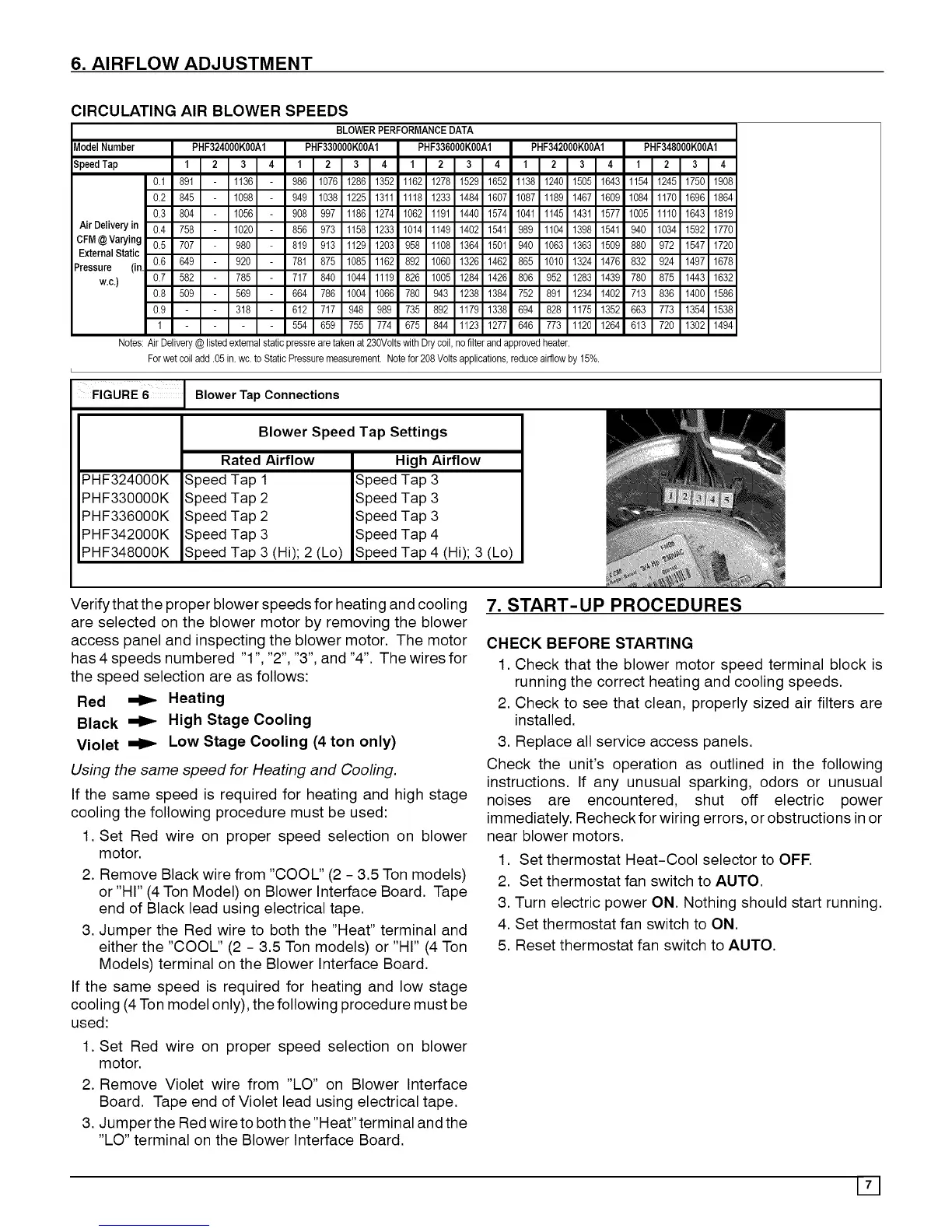

FIGURE 6

PHF324000K

PHF330000K

PHF336000K

PHF342000K

PHF348000K

Blower Tap Connections

Blower Speed Tap Settings

Rated Airflow

Speed Tap 1

Speed Tap 2

Speed Tap 2

Speed Tap 3

Speed Tap 3(Hi);2(Lo)

High Airflow

Speed Tap 3

Speed Tap 3

Speed Tap 3

Speed Tap 4

Speed Tap 4 (Hi);3(Lo)

I

Verify that the proper blower speeds for heating and cooling

are selected on the blower motor by removing the blower

access panel and inspecting the blower motor. The motor

has 4 speeds numbered "1", "2", "3", and "4". The wires for

the speed selection are as follows:

Red _ Heating

Black _ High Stage Cooling

Violet _ Low Stage Cooling (4 ton only)

Using the same speed for Heating and Cooling.

If the same speed is required for heating and high stage

cooling the following procedure must be used:

1. Set Red wire on proper speed selection on blower

motor.

2. Remove Black wire from "COOL" (2 - 3.5 Ton models)

or "HI" (4 Ton Model) on Blower Interface Board. Tape

end of Black lead using electrical tape.

3. Jumper the Red wire to both the "Heat" terminal and

either the "COOL" (2 - 3.5 Ton models) or "HI" (4 Ton

Models) terminal on the Blower Interface Board.

If the same speed is required for heating and low stage

cooling (4 Ton model only), the following procedure must be

used:

1. Set Red wire on proper speed selection on blower

motor.

2. Remove Violet wire from "LO" on Blower Interface

Board. Tape end of Violet lead using electrical tape.

3. Jumper the Red wire to both the "Heat" terminal and the

"LO" terminal on the Blower Interface Board.

7. START-UP PROCEDURES

CHECK BEFORE STARTING

1. Check that the blower motor speed terminal block is

running the correct heating and cooling speeds.

2. Check to see that clean, properly sized air filters are

installed.

3. Replace all service access panels.

Check the unit's operation as outlined in the following

instructions. If any unusual sparking, odors or unusual

noises are encountered, shut off electric power

immediately. Recheck for wiring errors, or obstructions in or

near blower motors.

1. Set thermostat Heat-Cool selector to OFE

2. Set thermostat fan switch to AUTO.

3. Turn electric power ON. Nothing should start running.

4. Set thermostat fan switch to ON.

5. Reset thermostat fan switch to AUTO.

Loading...

Loading...