EVOMAX - MULTILINE FLUE KITS

6

FLUE DESIGN

!

3.0 FLUE DESIGN

3.01

The following standards are relevant to the

construction, installation & testing of ue systems.

BSEN 14471 Plastic Chimneys –

requirements and test methods

BSEN 1856-1 Metal Chimneys – Requirements

BSEN 1859 Metal Chimneys – Test methods

BS 6644 Installation & Maintenance

of gas red hot water

boilers 70kW – 1.8MW

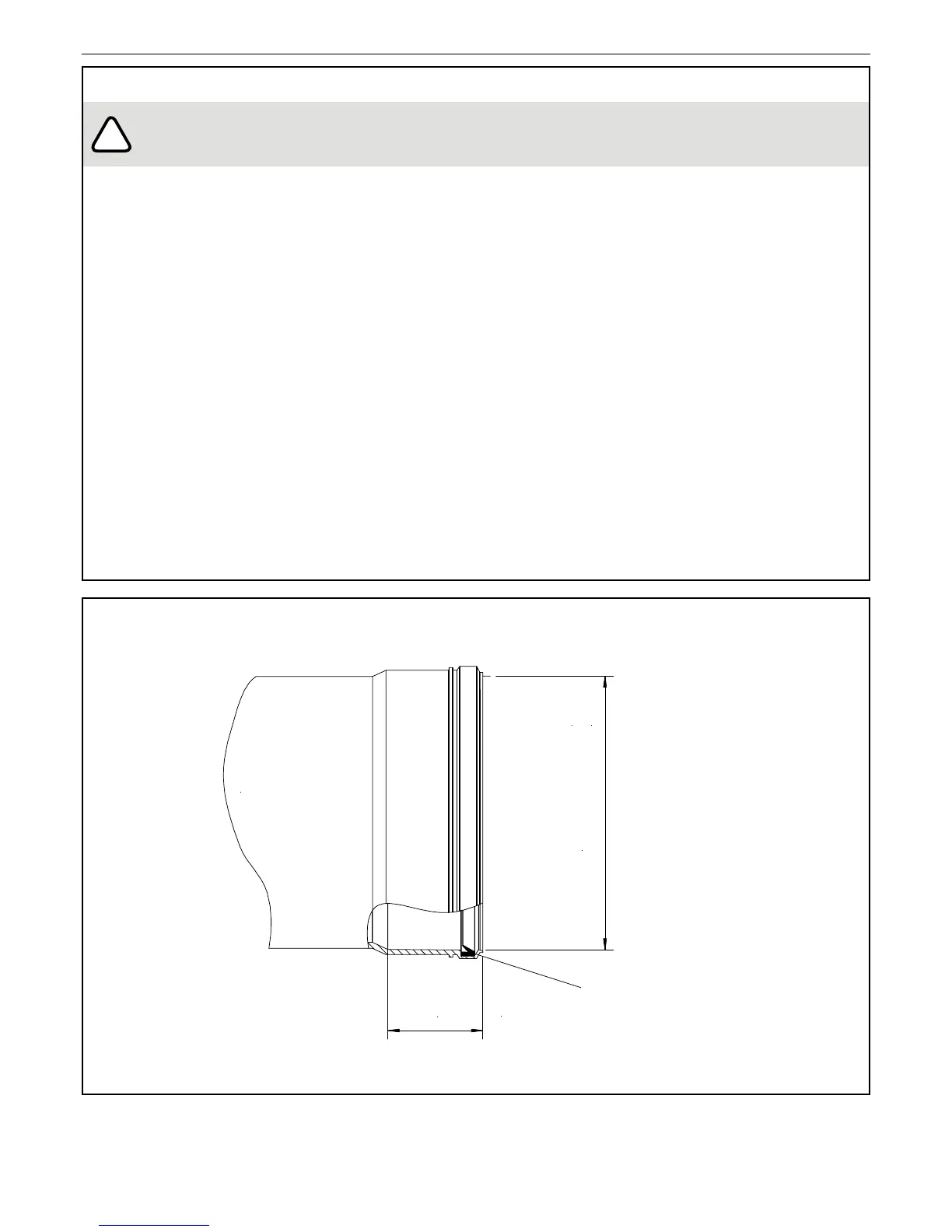

3.0.2 The Flue Stack must be specied by a Flue Specialist

3.0.3 Design of the connecting ue spigot must refer to the

dimensions of the mating collar (Fig 3.1).

3.0.4 The Polypropylene header and EPDM seal are certied

to BSEN 14471.

3.0.5 Integrity of the ue joints and safety of operation must

be proven by the installer.

3.0.6 The ue resistance at ‘A’ in Figure 3.2 is not permitted to

exceed the maximum static pressure specication [Pmax]

quoted in Table 3.3 when operating at the maximum

capacity.

IMPORTANT: LEAKAGE OF FLUE PRODUCTS INTO THE ROOM WILL DEPLETE

THE OXYGEN LEVEL & INHIBIT SAFE COMBUSTION

.

3.0.7 The ue route should be planned to enable the least

directional change, one elbow is recommended as

depicted in Figure 3.2.

3.0.8 The ue pipe diameter must be at least 200mm, larger

diameters will permit longer ue length.

3.0.9 The ue material must be suitable for condensing

operation.

3.0.10 The terminal guard must prevent the ingress of objects

greater than 15mm diameter to comply with EN15502.

3.0.11 The Flue Terminal design should be selected to create the

least resistance and not compromise the potential ue

length. A wire mesh type is recommended with a

14mm grid.

3.0.12 Rain ingress may be ignored as the header design

enables excess water to be discharged through the

condensate drain.

FIGURE 3.1

(CASCADE HEADER INTERFACE DETAIL - FEMALE FLUE SOCKET CONNECTION)

Loading...

Loading...