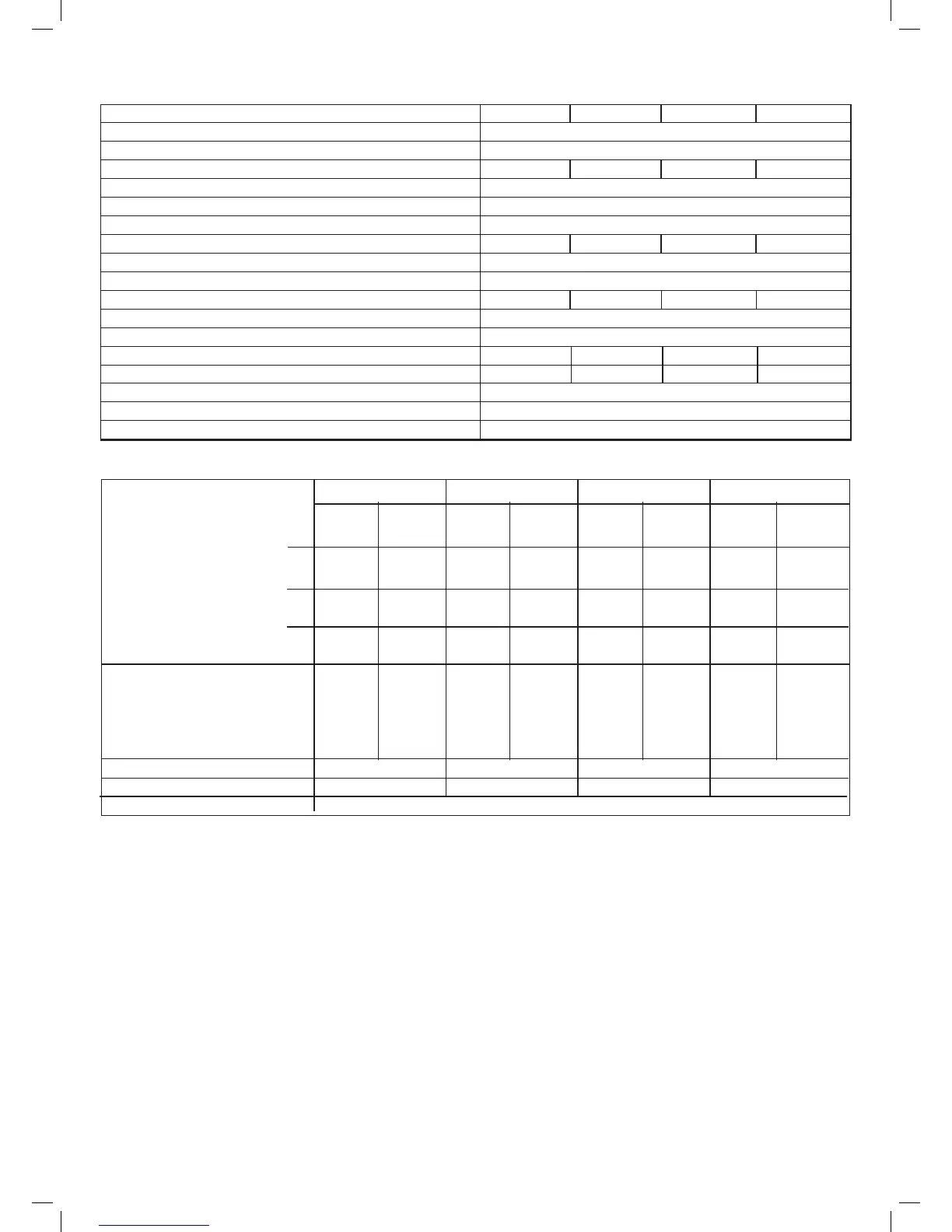

Ideal Logic System 15 18 24 30

Gas supply 2H - G20 - 20mbar

Gas Supply Connection 15mm copper compression

Injector Size (mm) 4.15 4.15 4.15 4.65

Flow Connection Central Heating 22mm copper compression

Return Connection Central Heating 22mm copper compression

Flue Terminal Diameter mm (in) 100 (4)

Average Flue Temp-Mass Flow Rate 56

o

C - 6g/s 58ºC - 8 g/s 63

o

C - 10g/s 69

o

C - 13g/s

Maximum Working Pressure (Sealed Systems) bar (lb/in

2

) 2.5 (36.3)

Electrical Supply 230 V ~ 50 Hz.

Power Consumption W 126 131 146 152

Fuse Rating External : 3A Internal : T4H HRC L250 V

Water content litre (gal) 1.2 (0.26)

Packaged Weight kg (lb) 34.4 (76) 34.4 (76) 34.4 (76) 34.4 (76)

Maximum Installation Weight kg (lb) 28 (61.7) 28 (61.7) 28 (61.7) 28 (61.7)

Boiler Casing Size Height mm (in) 700 (27.5)

Width mm (in) 395 (15.5)

Depth mm (in) 278 (11)

Table 1 - General Data

Note. Gas consumption is calculated using a

caloric value of 38.7 MJ/m

3

(1038 Btu/ft

3

) gross

or 34.9 MJ/m

3

(935 Btu/ft

3

) nett

To obtain the gas consumption at a different

caloric value:

a. For l/s - divide the gross heat input

(kW) by the gross C.V. of the gas (MJ/m

3

)

b. For ft

3

/h - divide the gross heat input (Btu/h)

by the gross C.V. of the gas (Btu/ft

3

)

c. For m

3

/h - multiply l/s by 3.6.

Key to symbols

GB = United Kingdom IE = Ireland (Countries of destination)

PMS = Maximum operating pressure of water

C

13

C

33

C

53

= A room sealed appliance designed for connection via ducts to a

horizontal or vertical terminal, which admits fresh air to the burner

and discharges the products of combustion to the outside through

orices which, in this case, are concentric. The fan is up stream of

the combustion chamber.

I

2H

= An appliance designed for use on 2nd Family gas, Group H only.

* The value is used in the UK Government’s Standard Assessment Procedure (SAP) for energy rating of dwellings. The test data from

which it has been calculated have been certied by a notied body.

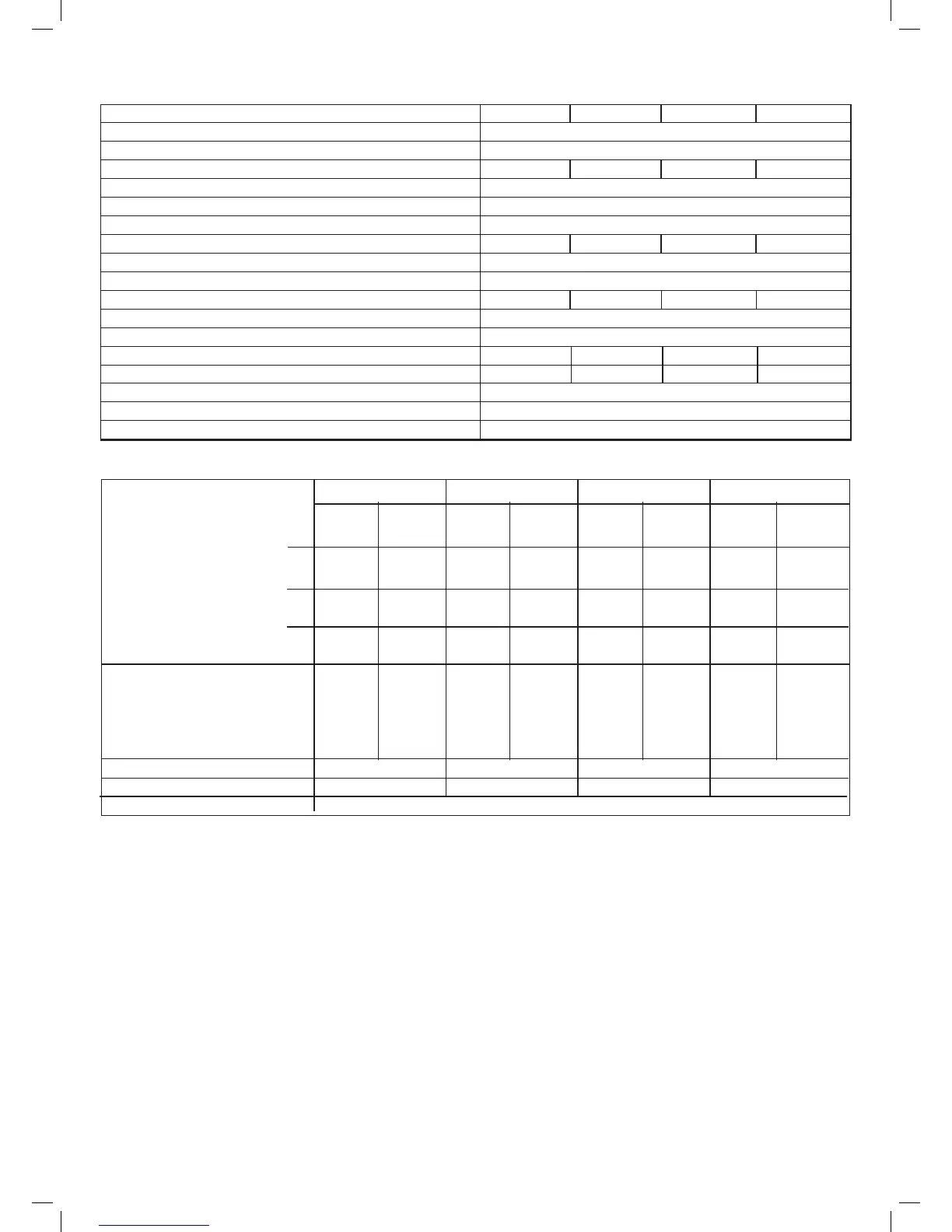

15 18 24 30

MIN MAX MIN MAX MIN MAX MIN MAX

Boiler Input :

Boiler Input ‘Q’ Nett CV kW 4.9 15.1 4.9 18.1 4.9 24.3 6.1 30.4

(Btu/h) (16,600) (51,520) (16,600) (61,800) (16,600) (82,900) (20,700) (103.600)

Gross CV kW 5.4 16.6 5.4 20.1 5.4 27.0 6.7 33.7

(Btu/h) (18,400) (56,800) (18,400) (68,600) (18,400) (92,000) (23,000) (115,000)

Gas Consumption m

3

/h 0.500 1.537 0.500 1.872 0.500 2.512 0.622 3.135

(ft

3

/h) (17.8) (54.7) (17.8) (66.1) (17.8) (89) (22) (111)

Boiler Output :

Non Condensing kW 4.8 15.0 4.8 18.0 4.8 24.2 6.1 30.3

70

o

C Mean Water temp. (Btu/h) (16,500) (51,300) (16,500) (61,600) (16,500) (82,600) (20,700) (103,300)

Condensing kW 5.1 15.9 5.1 19.1 5.1 25.6 6.4 31.0

40

o

C Mean Water temp. (Btu/h) (17,500) (54,250) (17,500) (65,100) (17,500) (87,400) (21,800) (105,800)

Seasonal efciency* SEDBUK 2005 91.1% 91% 91% 91.1%

Seasonal efciency* SEDBUK 2009 89.3 89.2% 89.5% 89.6%

NOx Classication CLASS 5

Table 2 - Performance Data - Central Heating

Loading...

Loading...