56

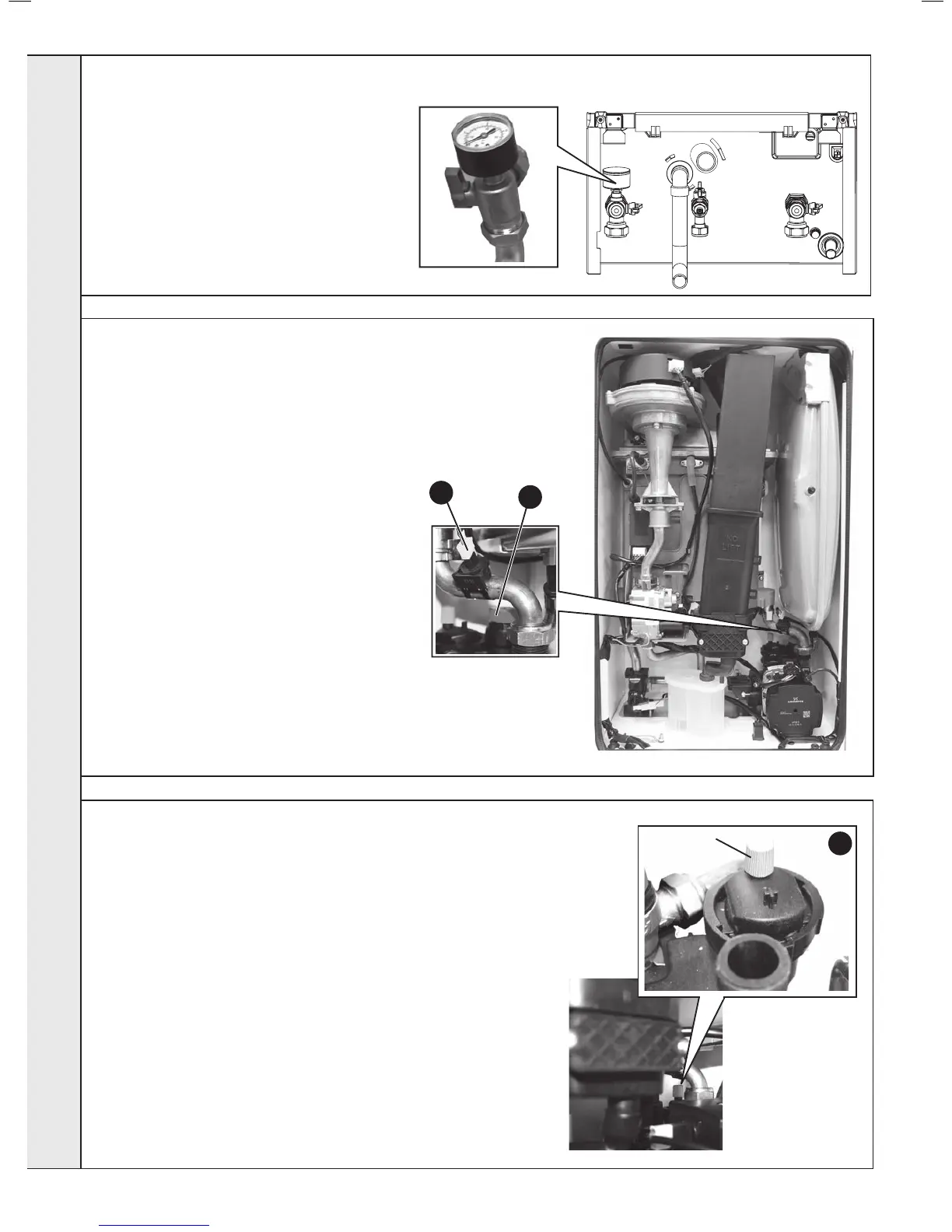

1. Refer to Frame 42.

2. Drain the heating system. Refer to

Frame 54.

3. Unscrew the pressure gauge and

discard.

4. Fit new pressure gauge, using suitable

jointing compound.

5. Rell the boiler. Refer to Frame 23.

6. Check operation of the boiler. Refer to

Frames 31 & 32.

55

PRESSURE GAUGE REPLACEMENT

57

1. Refer to Frame 42.

2. Drain the boiler. Refer to Frame 54.

3. Remove the expansion vessel. Refer to Frame 62.

4. Firstly, increase access area by disconnecting the 22mm pipe connection

at top of pump chamber and bottom of heat exchanger and remove pipe.

5. The automatic air vent head is retained in the pump body with a bayonet

connection. The air vent head and oat assembly is removed by turning

the head anti-clockwise (viewed from above) and pulling upwards.

6. Reassembly is the reverse of the above. Ensure the air vent head ‘o’ ring

seal is in place when retting and the new ‘o’ ring is tted to the return pipe

top connection.

7. Ensure the air vent cap is loose.

8. Rell the boiler. Refer to Frame 23. Check for leaks around the new air

vent joint.

9. Check the operation of the boiler. Refer to Frames 31 & 32.

5

Dust Cap

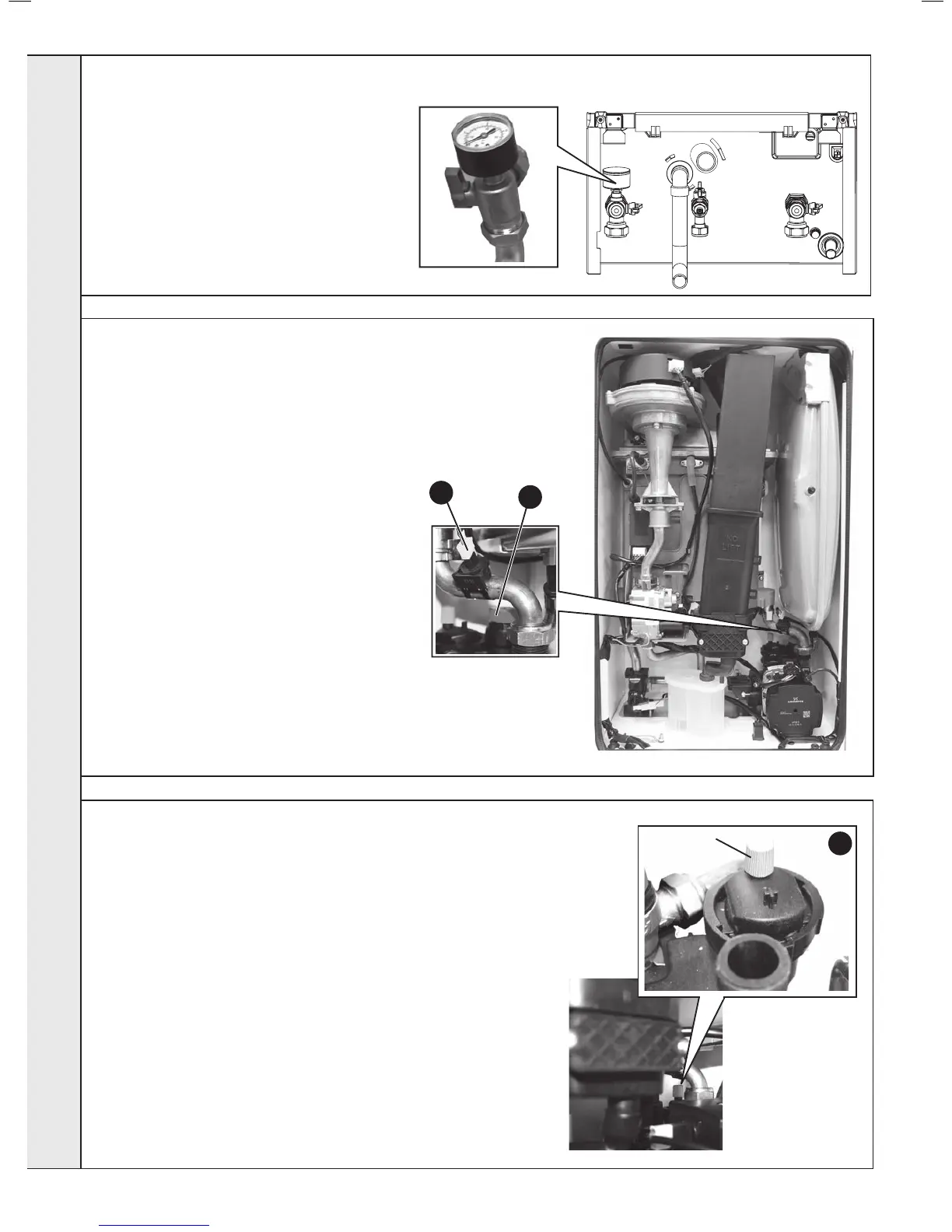

1. Refer to Frame 42.

2. Drain the boiler. Refer to Frame 54.

3. Remove the clip on return thermistor. Refer

to Frame 46.

4. Pull out and remove the clip (positioned

behind the safety valve) retaining the safety

valve.

5. Undo the safety valve pipe compression

tting positioned outside the boiler casing.

6. Lift out the safety valve/pipe assembly.

7. Remove the safety valve pipe and transfer

to the new safety valve.

8. Reassemble in reverse order ensuring the

retaining clip is correctly tted, the pipe

compression tting retightened and return

thermistor is re-clipped.

9. Rell the boiler. Check operation of the

boiler. Refer to Frames 31 & 32.

3

4

Loading...

Loading...