robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

GmbH | Martin Raak | Tel. +49 (0)2203 9649 409 | mraak@igus.de 12

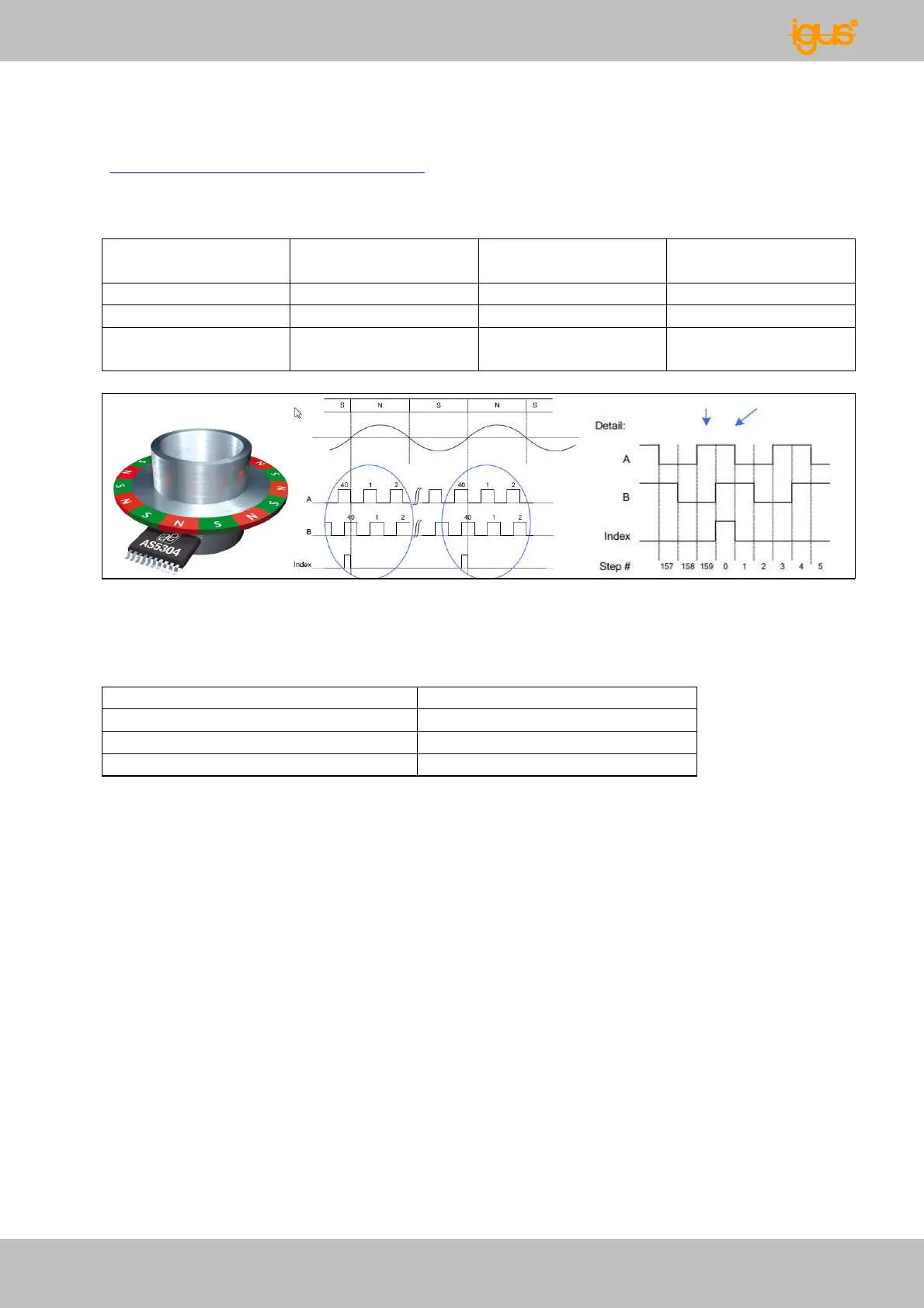

The encoder from Austriamicrosystems (=> Spec sheet download at

www.igus.de/robolink/support&service ) determines 4x40=160 A/B signals per pole pair.

This permits the following resolutions per axis:

chanel

(Quadratur)

Swivel RL-50-xxx 1.240 4.960 0,073°

Rotation RL-50-xxx 1.160 4.640 0,078°

Swivel / Rotation

RL90-xxx

2.480 9.920 0,036°

Fig. 25: A/B and index signals from the encoder

The resolution of the individual axis approximately corresponds to the following

positioning errors at the corresponding tube lengths:

Distance from center point (x) [mm] Positioning accuracy [mm]

200 0,24

400 0,49

500 0,61

Table 2: Positioning accuracy with angle sensors

Since the positioning errors for multiple axis are compounded, system designs have a

positioning inaccuracy, or repeatability accuracy of approx. 1-2mm for multi-axes systems

(depending on the number of axes and tube lengths).

The Hall Sensor Honeywell SS443A is used to reference the system (home position). It

has an Open-Collector-Output. This is designed for the connection to a TTL/CMOS-circuit

– the 10kΩ pull-up-resistance exists on the board already.

If the output has to be adapted to a 24V-circuit (e.g. PLC), it is realizable e.g. with the

following circuit diagram with an optical coupler device. The components have to be

adjusted to the respective loads. For this case, a possible electrical configuration is shown

in Fig. 26.

Loading...

Loading...