MAINTENANCE

IC75 ENG 4-10

CHECK THE FIXED BOLT TORQUE

Tighten the bolts and nuts as shown in the table below.

If loose bolts and nuts are found in daily check, tighten them. If lacking bolts and/or nuts are

found, be sure to replace new parts with lacking parts.

When a new machine is used, check the bolts and nuts when first 50 hours have past. Tighten

loose bolts and nuts.

Special torque specifications

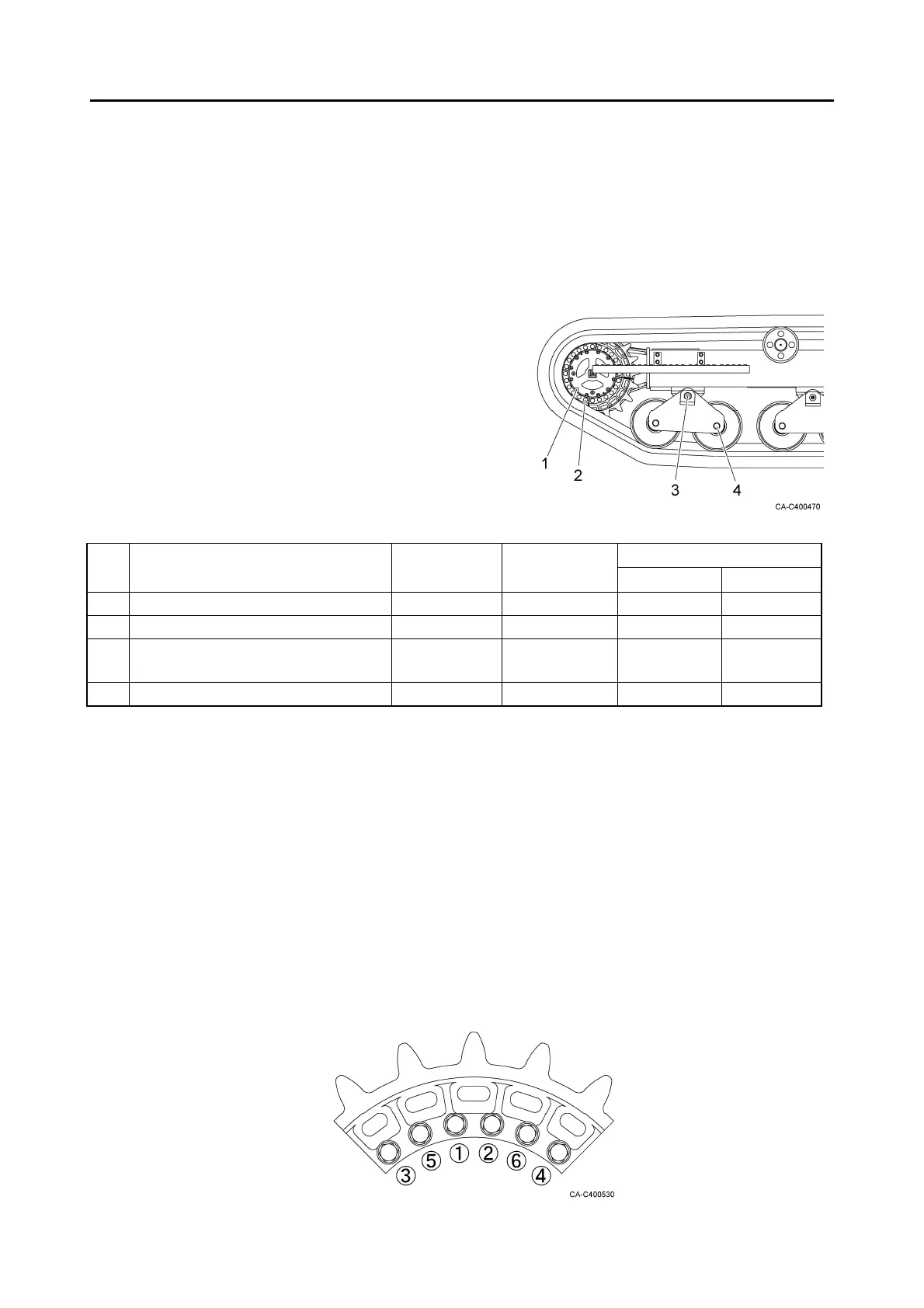

The bolts and nuts shown in the table below bear large

forces. Tighten them at the torques shown in the table.

When these bolts and nuts are replaced, apply

molybdenum disulfide grease to the threads and the

bearing surfaces of the nuts and tighten them at the

specified torques.

Traveling-rated

Tightening torque

No. Special tightening Thread size

Wrench size

(mm)

N⋅m

kgf-m

1 Travel reduction gear M16 24 241 24.6

2 Drive sprocket M16 24 241 24.6

3 Oscillating link

M30

Castle nuts

46 476 48.6

4 Lower roller M24 36 850 86.7

Precautions for installing the travel reduction gear and drive sprocket

1. Apply screw locking agent to the threads of bolts No. 1 and No. 2.

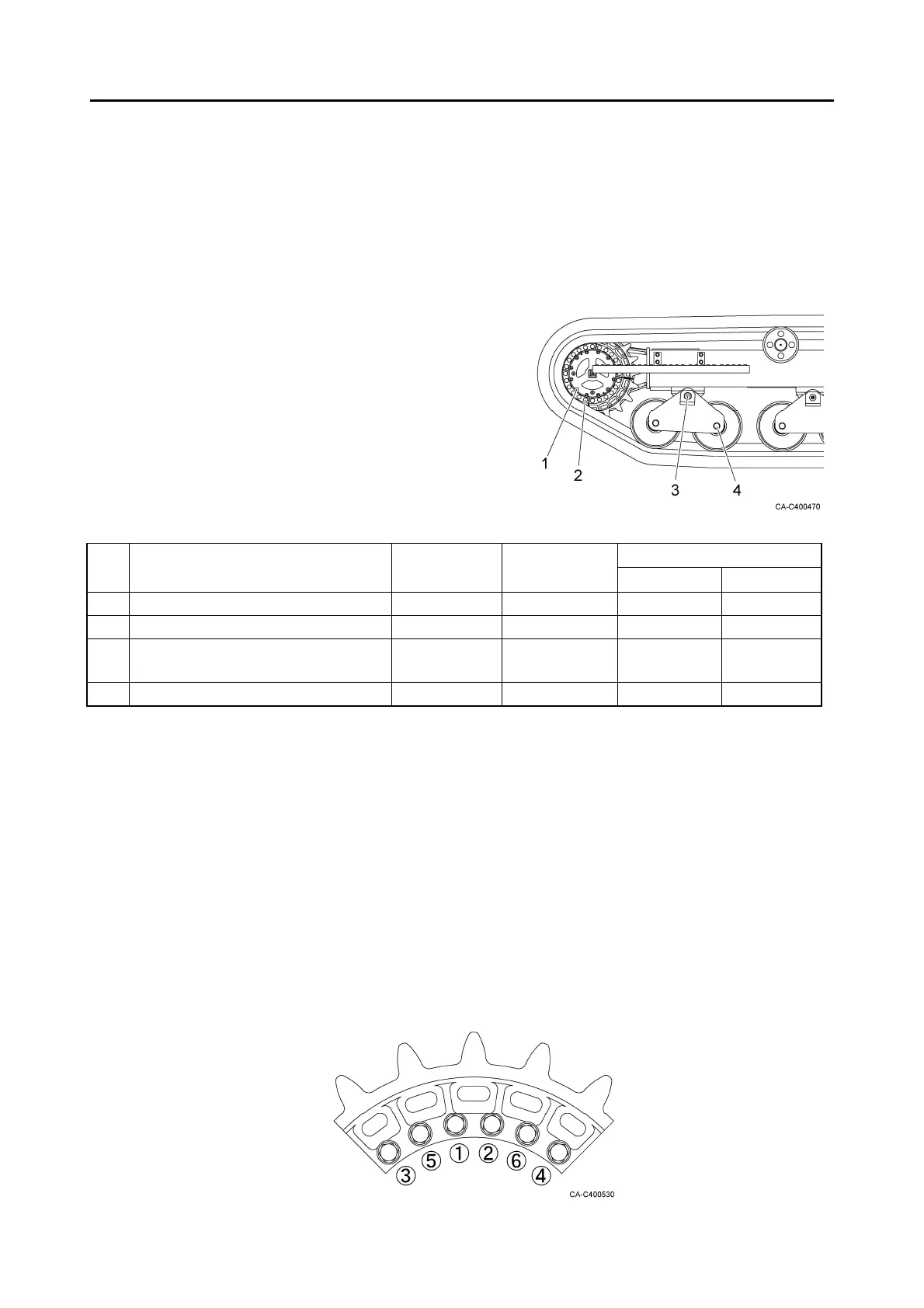

2. Observe the following procedures when attaching the drive sprocket.

(1) Bring the inner surface of the sprocket into close contact with the motor spigot when

attaching the sprocket.

(2) Tighten all of six bolts with screw locking agent applied at a torque of 98 to 156.9 N⋅m

first.

(3) Then, tighten the bolts in the order shown on the right at the specified torque of 241 N⋅m.

Tighten the bolts quickly since screw locking agent is applied to them.

Loading...

Loading...