Chapter 7 Usage of Various Functions

7-

ొ

6) Program Example

(1) System configuration

(2) Initial setting

a) PID operation parameters

Auto / Manual operation setting : Auto

Forward / Reverse operation : Forward

SV setting : 960(60°C ),1120(70°C ),1280(80°C ),1600 (100°C)

Current value setting : D4980(AD conversion value of AD module Ch1)

BIAS setting : 0 (If only P control is used, input proper value other 0)

EN_P, EN_I, EN_D setting: EN_P=1, EN_I=1, EN_D=1 (PID operation)

REF=10 , TT=50 , N=1

MV_MAX, MV_MIN, MVMAN: MV_MAX=4000, MC_MIN=0, MAMAN=2000

S_TIME : S_TIME=100 (sampling time = 10 seconds)

b) Auto-tuning parameters

PV setting: : 960(60°C ),1120(70°C ),1280(80°C ),1600 (100°C)

S_TIME: S_TIME=100 (sampling time = 10 seconds)

Current value setting : D4980(AD conversion value of AD module Ch1)

wave select : designation value=1

c) A/D module setting

Channel setting : use channel 1

input range setting : DC 4 ~ 20 mA

A/D conversion data registration area : D4980

Output data type: – 48 ~ 4047

d) D/A module setting

output range setting: DC 4 ~ 20 mA

D/A conversion data registration area : D4982

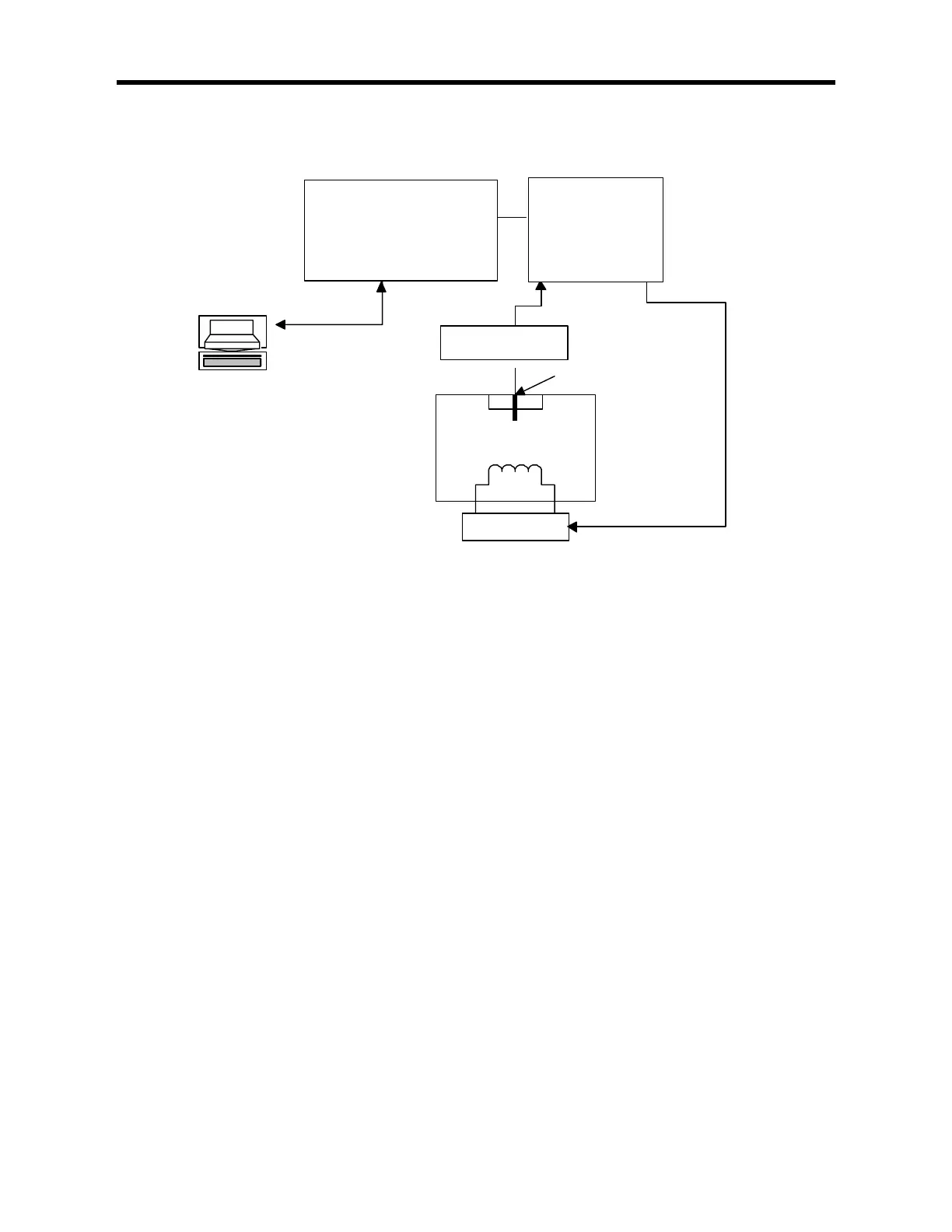

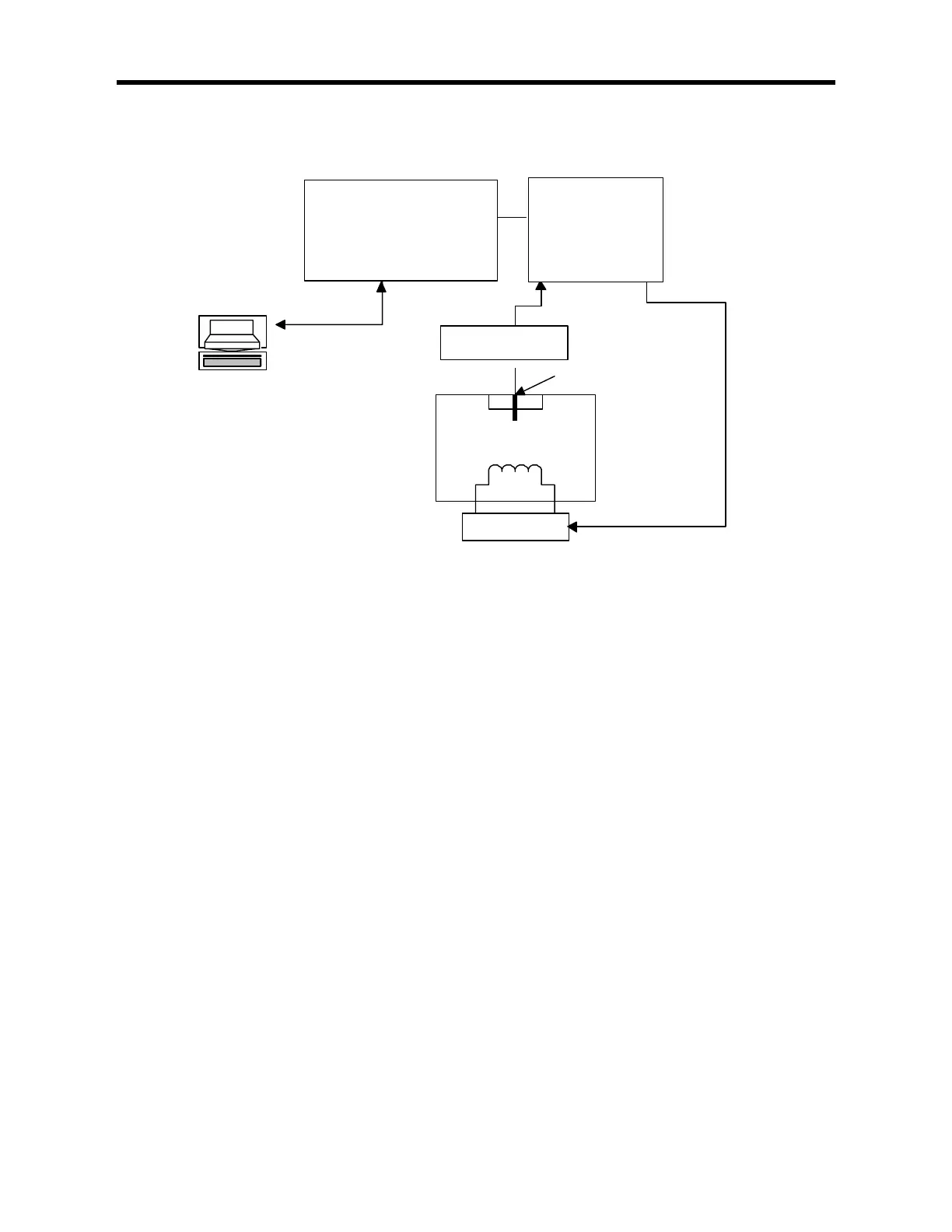

K7 Base unit

RS -232C

Transformer

Heater

Signal transforming

device

PV: DC4~20mA

1~5V

MV: DC4~20mA

1~5V

G7F-ADHA

KGLWIN

(V2.0 or later)

Electric oven

(0 ~ 200°C)

Loading...

Loading...