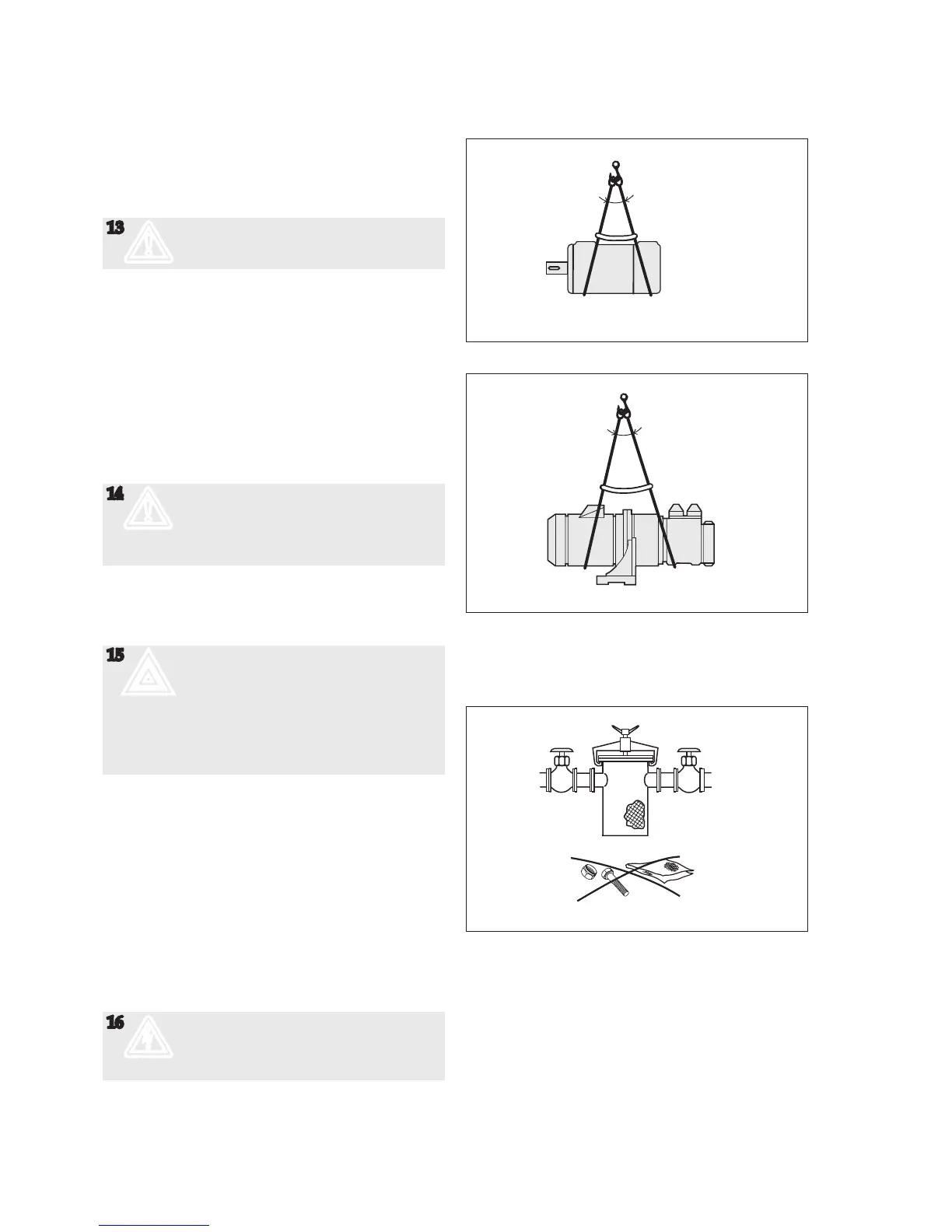

Fig 1. Liing the pump

Design limitations and technical data for each pump

are found in the Product description. Installation of

IMO AB low pressure pumps does not require special

skills. However, these instructions presume that the

work is carried out by experienced ers!

13

m

Failure to comply with these instructions

may cause damage and personal injury

Transport and storage

Always protect the pump against ingress of water and

other impurities. Store the pump in a clean, dry and

warm environment. The pump is delivered with the

internals oiled and with protective covers over the

pipe connections and drain openings. These covers

should remain in place for as long as possible during

the mounting and installation procedure but must be

removed before start up.

Lifting of pump

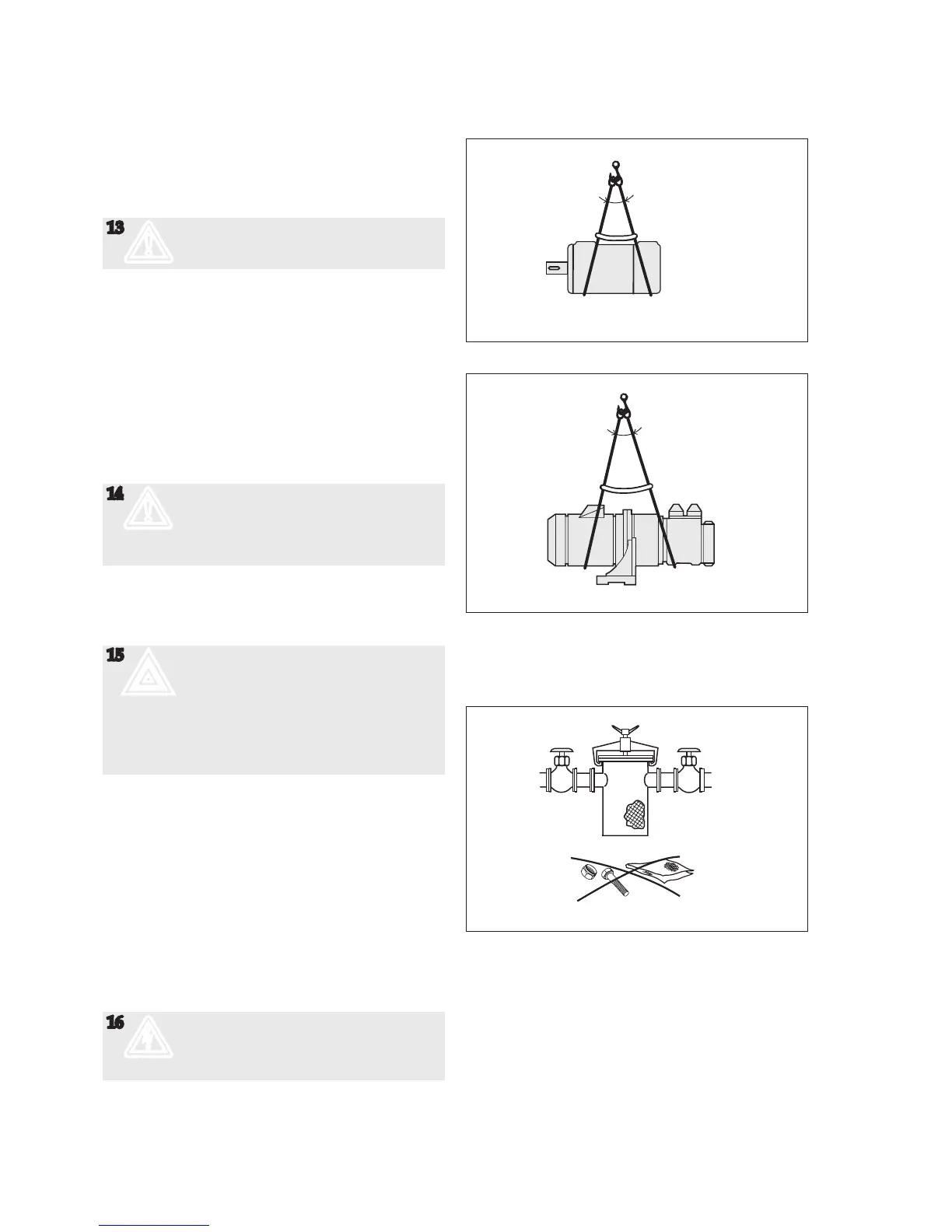

14

m

All pumps should be lied with straps

securely aached to the pump or pump

unit, so that the center of gravity is located

between the straps in order to avoid

tipping of the pump.

Liing of the complete pump unit with the liing

device aached to the motor, should be avoided as the

motor’s liing provisions may not be able to carry the

combined weight of the pump and motor.

15

;

The installation must be designed

to minimize damage. Should an

operational or functional failure occur.

E.g. precautions should be considered to

collect oil spillage due to a broken pipe or

pump housing, to stop pump operation

if overheating should occur or if the oil

volume is below a minimum tank level.

Allignment and shaft couplings

The pump shall be connected to its driver via a exible

sha coupling; they may also be driven via gears or

pulleys as specied in the Product Description, pro-

vided that the radial forces are kept within the specied

range. An angular misalignment of 0.1° corresponds to

approximately. 0.2 mm deviation/100 mm. The coupling

and alignment shall be selected not to transmit any ax-

ial or radial loads on the sha ends. IMO AB standard

couplings shall have a distance between the coupling

halves as per table, g 4. The coupling halves shall be

secured by lock screws. For other types of couplings,

please refer to respective maker’s manual.

16

c

When ing the sha coupling, do not use

a hammer or similar as this may damage

the ball bearing and sha seal.

Use some kind of press tool.

Fig. 2 Strainer

Installation

Loading...

Loading...