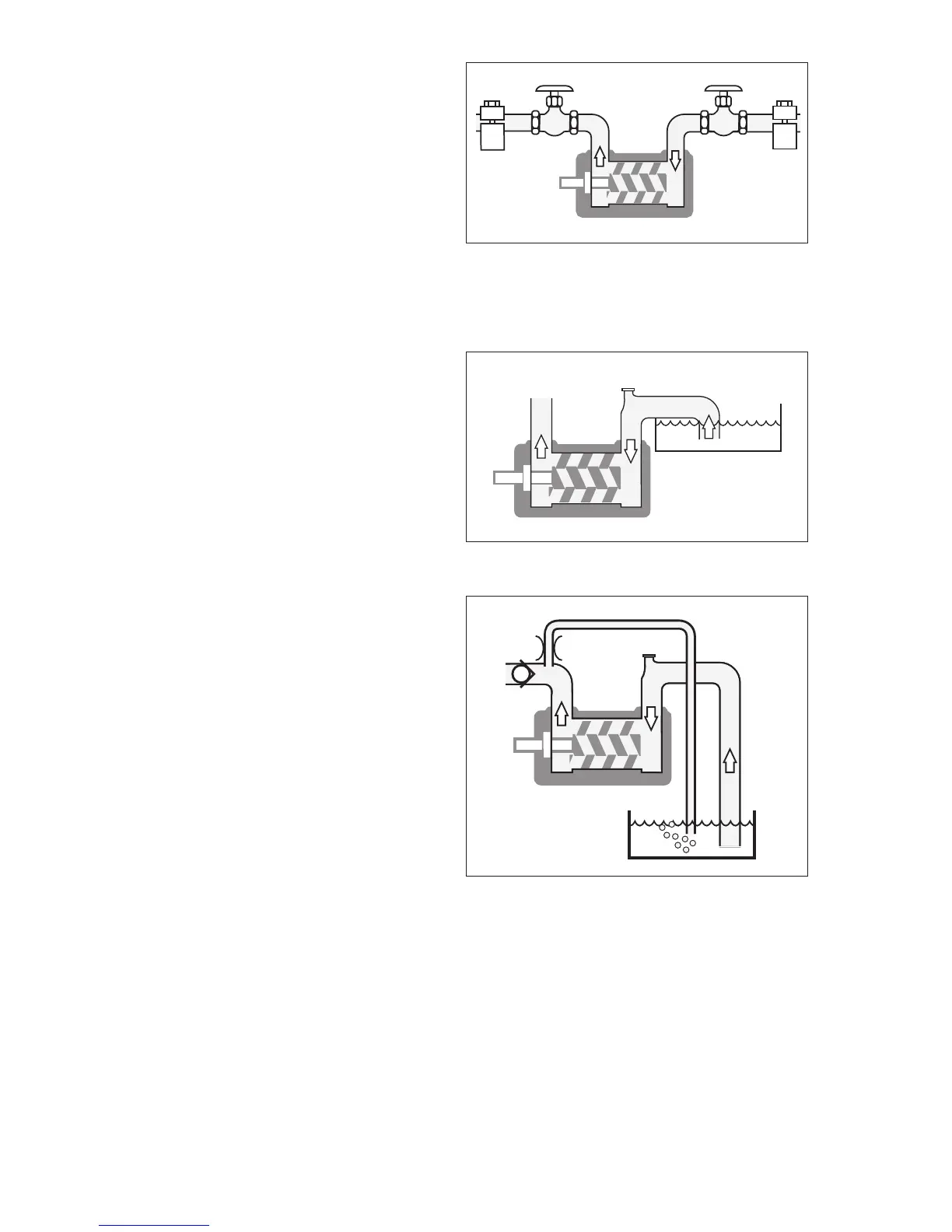

Fig. 7 Deaeration

Pipe connections

The pipe work shall be installed and supported so that

no pipe stresses are transferred to the pump body. The

pipe work should be tight in order to avoid leakage

and inltration of foreign particles and/or air. Shut o

valves should be installed in both suction and dis-

charge pipes, so that the pump can be hydraulically

isolated.

Suction line

The suction pipe should be designed so that the total

pressure drop, measured at the pump inlet ange, does

not exceed the suction capability of the pump. Make a

proper calculation of the suction line including com-

ponents such as valves, strainer, pipe bends etc. Gener-

ally, the pressure drop in the suction line should be as

low as possible, which is achieved if the suction pipe is

short, straight and has a suitable diameter. The veloc-

ity in the suction line should be kept in the range 0.5

- 1.2 m/s. For L.O. circulating systems, we recommend

to keep it as low as possible. The suction line must

be equipped with a port that allows lling the pump

before start.

Discharge line

The discharge line should be dimensioned to keep the

velocity in the range 1 - 3 m/s.

Deaeration

In installations with negative suction head, where the

pump might be started against a pressurized system, a

deaeration pipe with an orice (2-3 mm is recommend-

ed) has to be installed. The deaeration pipe should be

connected to the outlet pipe’s highest point. This must

also be installed when the pump is used as a stand-by

pump.

Shaft seal drain

The pump should be installed so that any leakage from

the sha seal does not become a hazard. As the sha

seal has to be lubricated a small amount of oil dripping

cannot be avoided. Provisions to collect the leakage

from the sha seal must be made. A drain pipe can

be connected to the drain connection on the pump.

However, when pumping heavy fuel oil or any other

liquid that is likely to become very viscous at ambient

temperature, we recommend that the liquid is allowed

to drop freely from the drain opening.

Liquid trap

In some mounting arrangements the pump may not

retain the liquid at stand still. In such installations the

suction pipe should be arranged so it forms a liquid

trap together with the pump, keeping the pump half

lled with liquid.

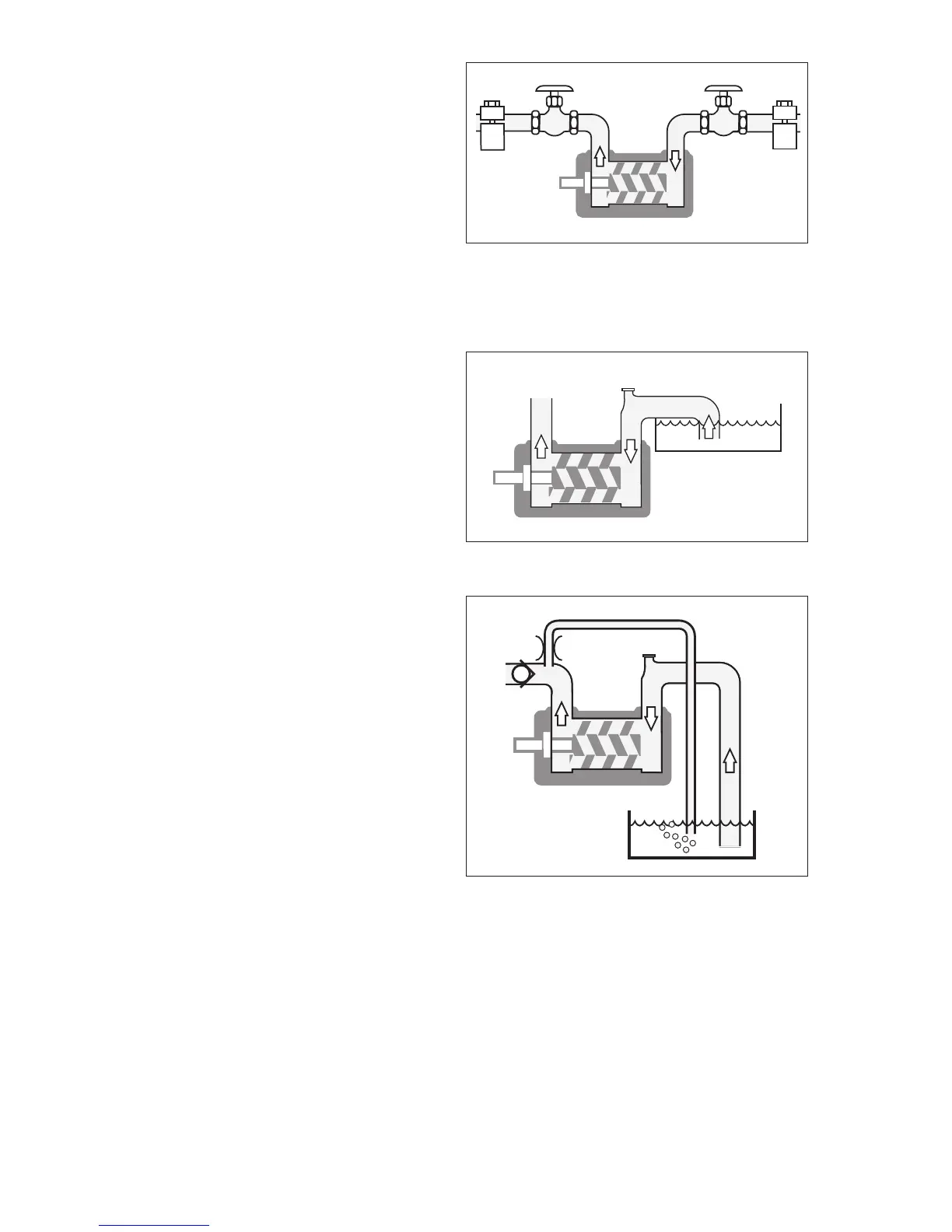

Fig. 5 Pipe connections

Fig. 6 Suction Line

Loading...

Loading...