ACF5 0601.01 GB

www.imo.se

21

Starting

Check that all valves necessary for the operation are

fully opened in both discharge and suction lines.

The rst time, the pump should be started with the ad-

justing spindle of the pressure relief valve tightened to

half of the available turns (the valve seing is increased

when the spindle is turned clockwise). By monitor-

ing the pressure gauge it can be determined when the

suction line is primed and the pump begins to work.

Should the pump not operate normally soon aer start,

stop the pump within half a minute. Start again aer

about 3-5 minutes (the sha seal must have time to cool

o) and run for half a minute. This procedure may need

to be repeated a couple of times if the suction line is

extremely long. Should the pump still not work, it must

be assumed there is a problem in the system that needs

to be remedied. Check the suction line calculation or

see”Trouble shooting”, page 22.

Setting the pressure relief valve

The seing of the opening pressure is made as follows:

Tighten the valve spindle by rotating clockwise to the

maximum extent. The system pressure is regulated by

throling to required value. The pressure relief valve

is eased until the pressure is just beginning to decrease

by turning the spindle CCW. The valve is now preset

for desired opening pressure. Open the throling valve

entirely.

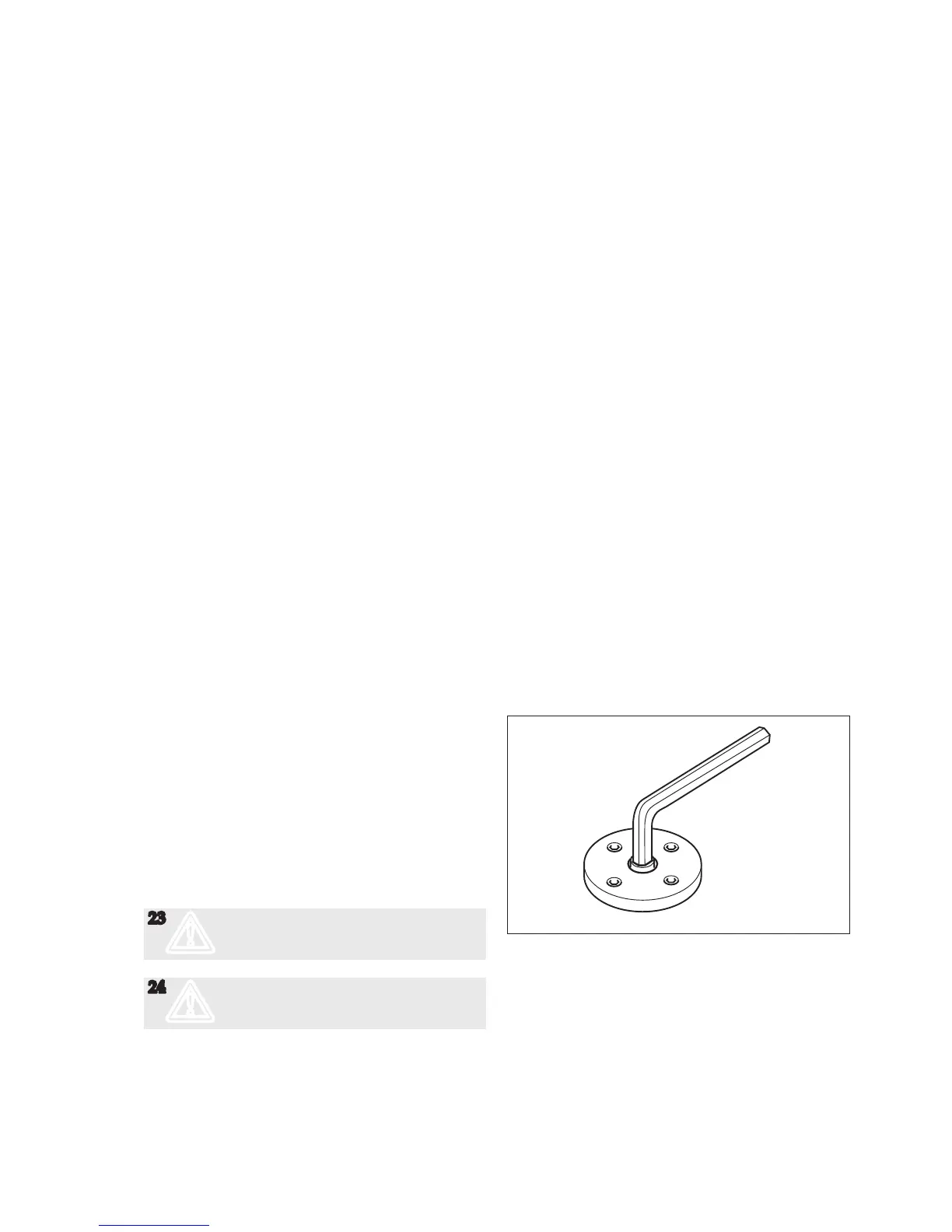

Adjusting the tuning

The tuning adjustment, which is a standard feature on

ACF pumps, is a device for minimizing the eects of

dissolved and free air in lube oil systems. The tuning

principle is described in the Product Description. The

tuning should be adjusted while the pump is working

under normal operating conditions. This is done by

turning the tuning spindle with an Allen key (size 12

mm for ACF) to a position where the noise level comes

to a minimum.

Setting of tuning of the ACF:

1. Before starting the seing, check that the seing

screw are closed.

2. Turn the screw CCW until the noise level becomes

the lowest (if turned too much the noise will increase

again).

Once set, the tuning needs no further adjustment, pro-

viding the operating conditions stay the same.

NOTE: It´ s not possible to accidentally turn the tuning

spindle too far as it is internally locked at the end of the

thread.

23

m

If operating temperature exceeds 60°C

(149°F), appropriate measures to avoid

skin contact shall be provided

24

m

Use hearing protection whenever high

noise can be expected from pump, motor

and/or environment.

Fig. 10 Tuning the ACF

Loading...

Loading...