ACF5 0601.01 GB

www.imo.se

17

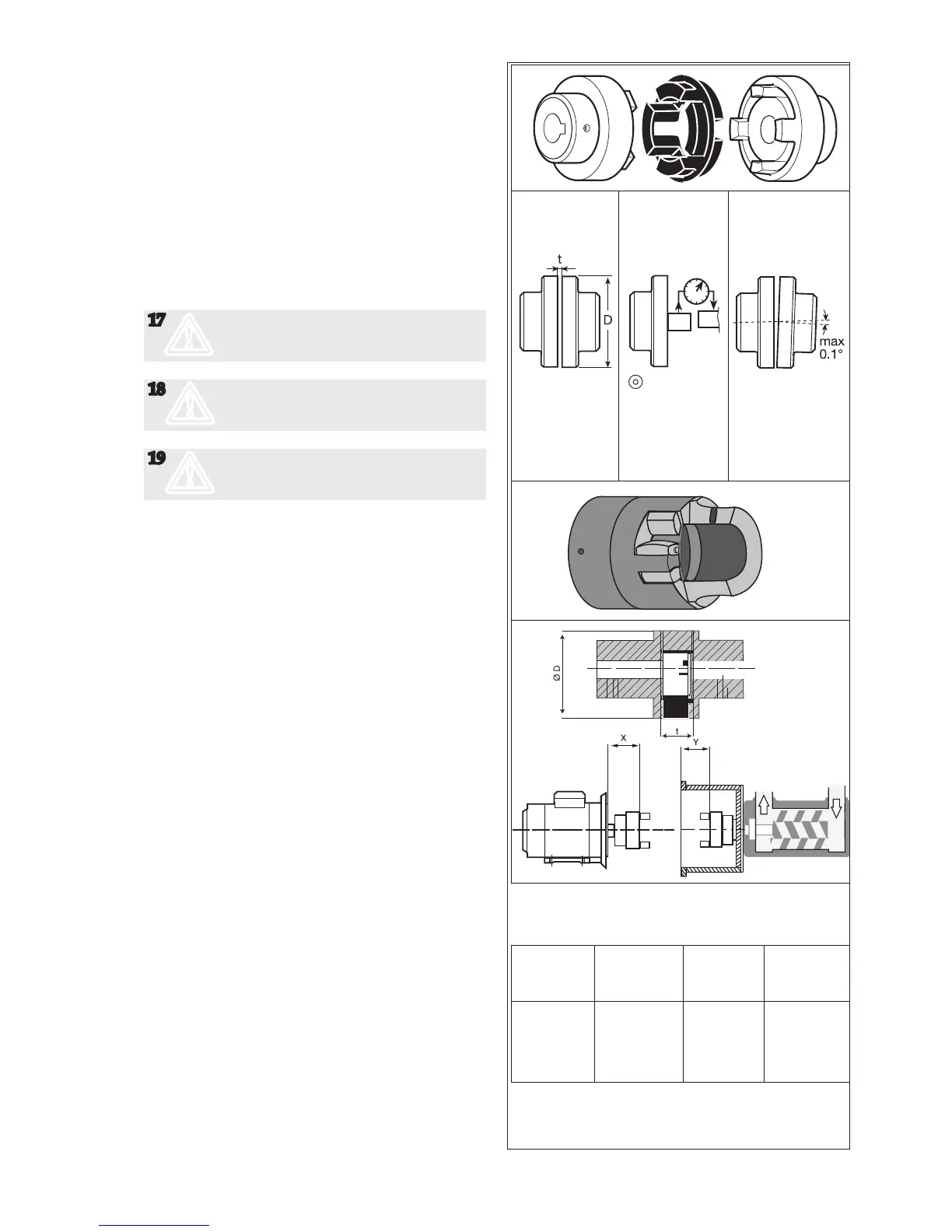

Strainer

The pump has to be protected from foreign maers

such as weld slag, pipe scale, etc., that could enter the

pump via the suction line. If the cleanliness of the sys-

tem cannot be guaranteed, a strainer must be installed

in the inlet pipe near the pump. For practical reasons

a suction strainer with 0.8-2.0 mm mesh openings is

recommended.

The size of the strainer should be selected so that it is

large enough to allow adequate pressure at the pump

inlet. The pressure drop across the strainer should

preferably not exceed 0.1 bar at max. ow rate and nor-

mal operating viscosity. A vacuum gauge between the

strainer and the pump inlet is recommended to indicate

when the strainer needs cleaning.

17

m

Oil leakage may make the oor slippery

and cause personal injury

18

m

When handling liquids that may harm

skin, use gloves and/or protective clothing

19

m

When handling liquids which may involve

re hazard, appropriate precautions to

avoid danger are to be taken.

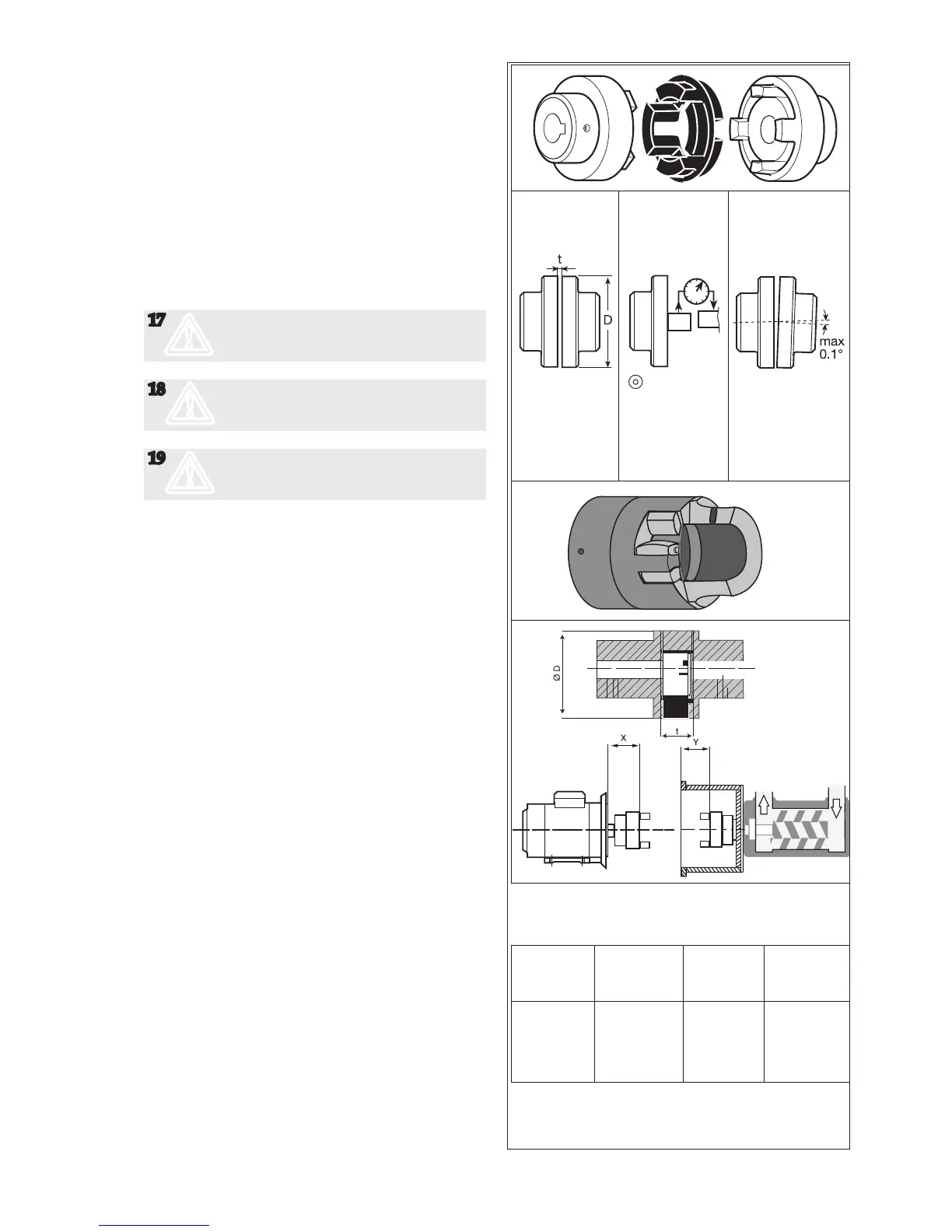

Fig. 4 Distance between coupling halves.

(IMO AB standard coupling)

Outer diameter

of coupling

(D mm)

Distance between

coupling halves

(t mm)

Outer diameter

of coupling

(D mm)

Distance between

coupling halves

(t mm)

A B A B

50 26 2.0 8 148 3.5

67 40 2.5 16 168 3.5

82 55 3.0 18 194 3.5

97 65 3.0 20 214 4.0

112 80 3.5 24 240 4.0

128 95 3.5 26

Fig. 3 Alignment of the IMO AB standard coupling

D4 ø max 0.3 mm

D6 ø max 0.4 mm

E4 ø max 0.4 mm

See table below

An angular

misalignment of

0.1° corresponds to

approx. 0.2 mm

deviation/100 mm.

Angular

alignment

Distance

between

coupling halves

Circular

run-out

A

x = y - t

B

Loading...

Loading...