99903514:TELESCOPIC CRANE: 3-12 SECTION 3: REPAIR

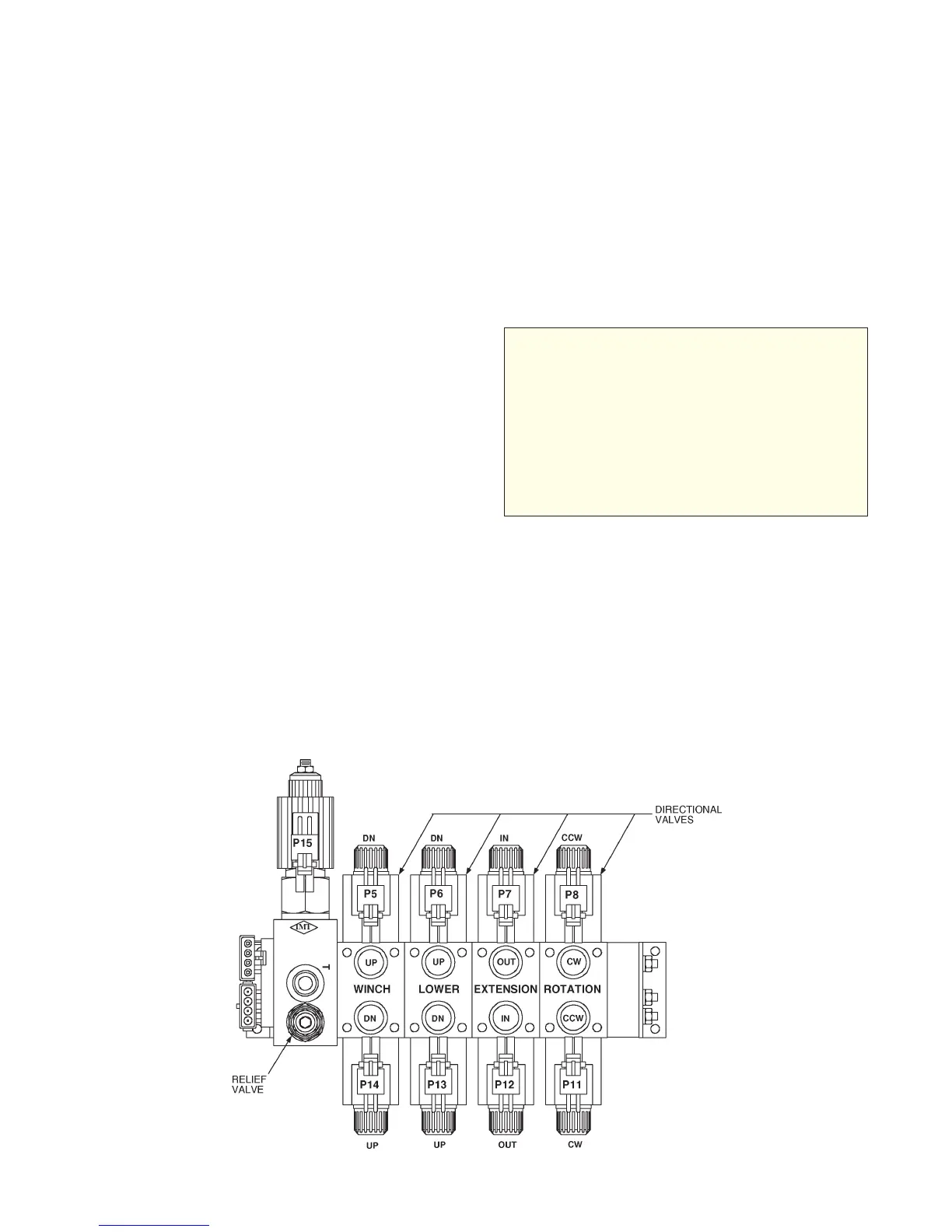

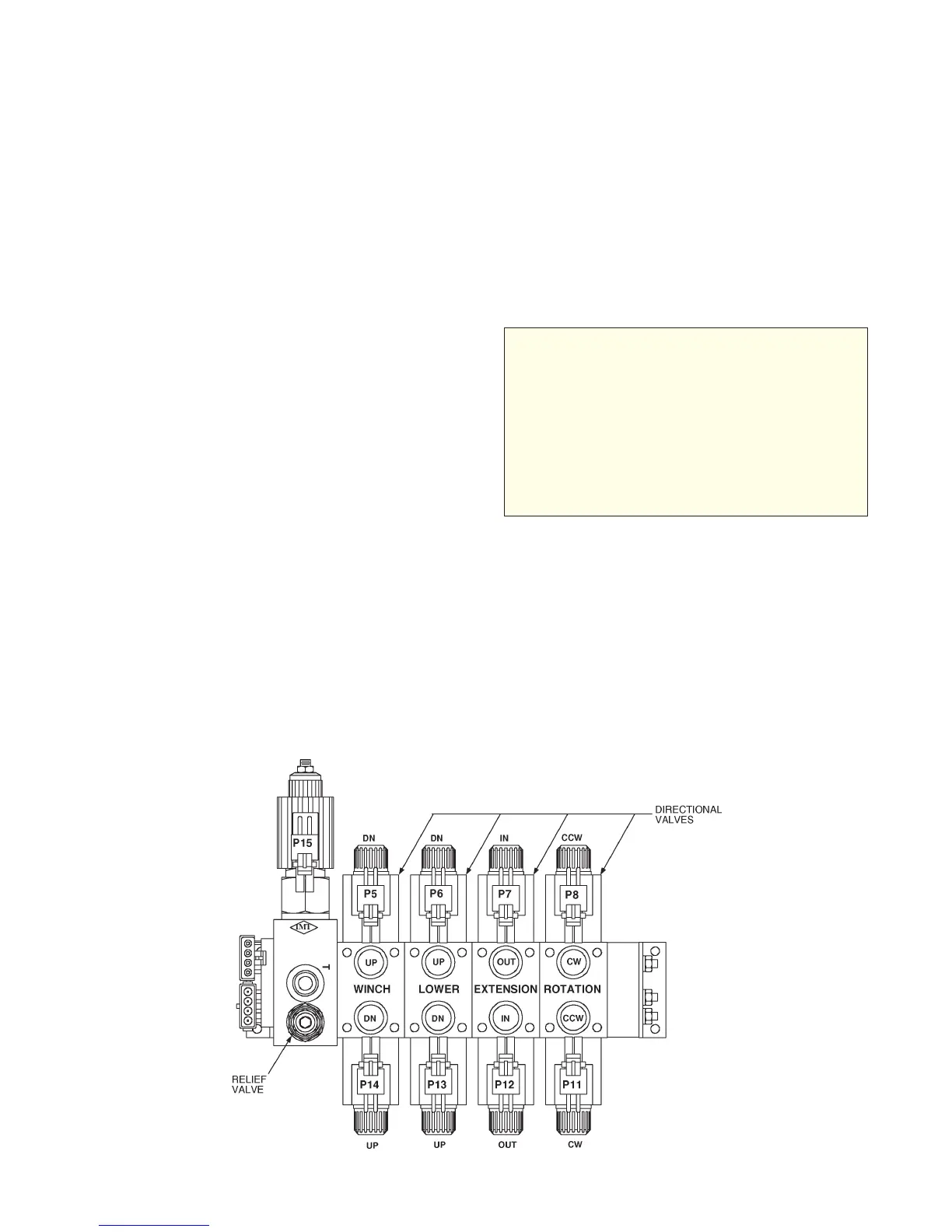

HYDRAULICS-VALVEBANK

RELIEF VALVE

The relief valve limits the maximum system

pressure. Pressure limits the amount of torque

or force an actuator will see. This pressure is

preset to 3000 psi at 10 gpm. If the relief valve

should fail, it would likely stick open. This would

prevent system pressure from developing and

cause a lack of torque/force at the actuator.

The relief valve can be changed easily by

screwing it out and replacing with a new one.

PROPORTIONAL VALVE

The proportional valve varies the oil flow to the

individual crane functions. Doing so dictates the

speed of the crane functions. As the electrical

current (0.2 to 2.2 Amps) increases to the valve,

by using the trigger on the control handle, more

oil is ported downstream to the crane function.

If the valve coil burns out, the operator would be

unable to vary the flow to the crane functions. If

the valve spool becomes stuck, the operator

would be unable to vary the downstream flow. If

speed control is the problem, it is likely an

indication of a proportional valve problem. It is

necessary to verify that current is flowing to the

coil correctly, and that it is not an electrical

problem.The proportional valve can also be

operated manually for test purposes. The valve

stem can be screwed in manually to port oil

downstream. Doing so will manually position

the valve spool and hold it in the manually

commanded position.

Figure C-13: Valvebank Functions and Features

DIRECTIONAL VALVES

The directional valves (4) control the direction of

the crane functions. When one of the solenoids

is energized, it shifts the valve spool. This

allows oil to flow out one of the valve ports. If a

function does not work, a directional valve may

be to blame.These valves have a standard

manual override. You may manually shift the

valve by pushing the pin, located in the middle of

the solenoid.

CAUTION

MANUALLY OVERRIDING A DIRECTIONAL

VALVE WILL PORT OIL IMMEDIATELY TO

THE VALVE FUNCTION. THIS WILL

CAUSE A SUDDEN MOVEMENT OF THE

ACTUATOR. OPERATORS AND MAINTE-

NANCE PERSONNEL MUST KEEP THE

WORK AREA CLEAR OF OTHER PER-

SONNEL WHEN OVERRIDING A DIREC-

TIONAL VALVE.

If the valve shifts using manual overrides, the

problem is of an electrical nature. Valve coils

are interchangeable and may be changed by

removing the coil nut. This allows maintenance

personnel to isolate individual coil failures. If the

valve cannot be actuated manually or electri-

cally, it is necessary to replace the section.

20030115

Loading...

Loading...