99903514:TELESCOPIC CRANE: 3-5 SECTION 3: REPAIR

5. Install and tighten remaining bolts in the

correct sequence with the correct torque,

using the torque chart and the torque se-

quence in the General Reference section of

this manual.

3-9-3: WORM END PLAY & BACKLASH -

INTEGRAL BASE & WORM DRIVE (3020,

3820, 5020, 5525, 6025, 6625)

Crane models 3020, 3820, 5020, 5525, 6025,

6625 have an integral base and worm drive

rotation system.

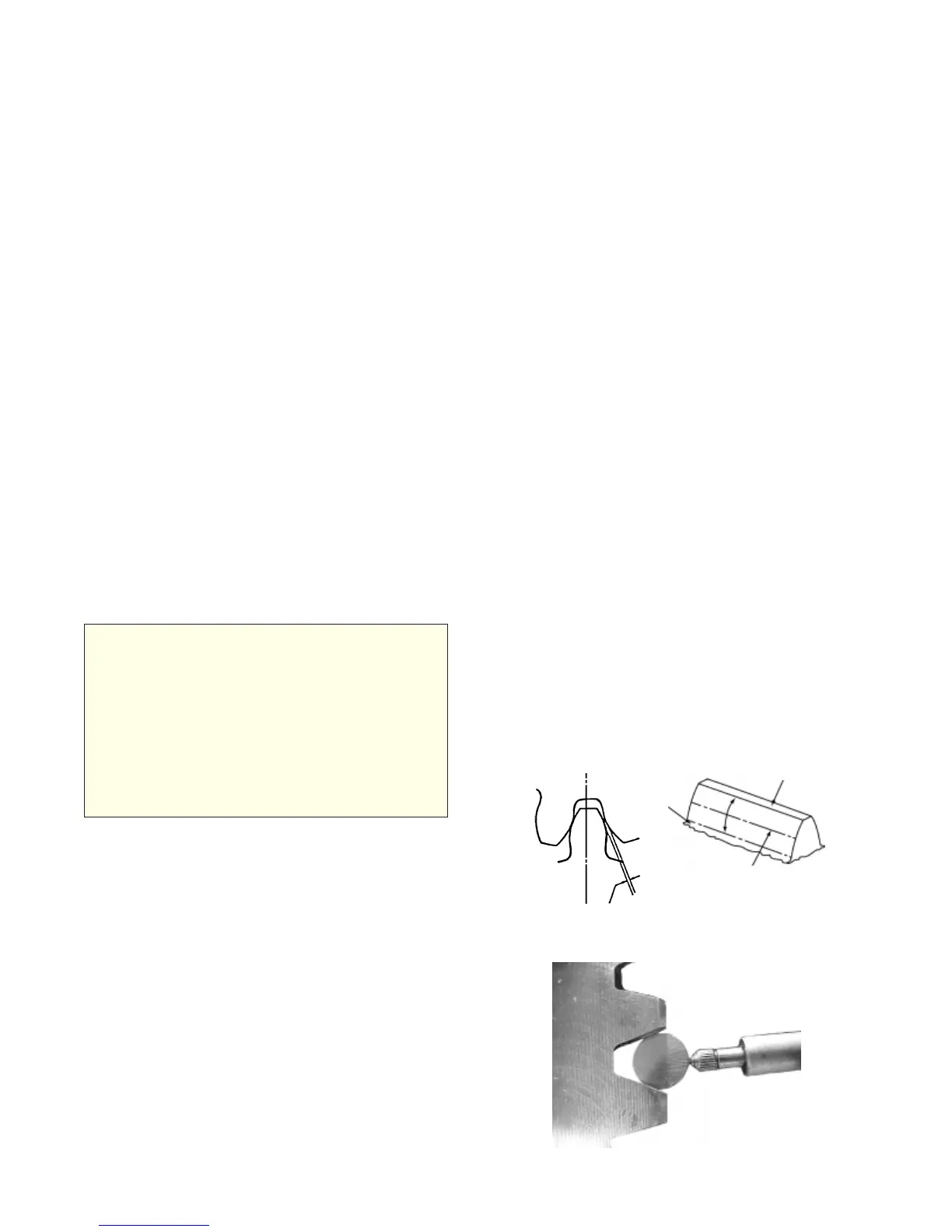

To set both Worm End Play and Backlash, you

must locate the high tooth on the gear. Usually

this spot is marked by the manufacturer with

light blue paint. If you cannot find the paint

mark, identify the high tooth using a dial indica-

tor with a magnetic base and a round steel pin

which is large enough to contact the bearing

near the pitch line of the bearing tooth. Set the

indicator base on the face of the bearing race

that does not have teeth. Place the pin between

two of the teeth. Set the indicator probe on the

pin and adjust the dial to zero. Rotate the

bearing, checking every third tooth until you find

the highest indicator reading. Check three teeth

in both directions in this area to determine the

highest tooth. The amount of run-out varies

depending on the diameter of the bearing. Once

you find the high tooth, mark it for future refer-

ence.

3-9-1: REMOVING THE CRANE ROTA-

TION SYSTEM

1. Retract extension booms, and support both

the crane and mast fully.

2. Lower the boom so that the boom tip is as

low as possible.

3. Cinch two slings or a hoist on opposite

sides of the boom center of gravity. Hook

slings on hoist and raise hoist to tension the

slings.

4. Identify, mark, and remove hose connection

between the crane base and boom. Cap or

plug all open hydraulic fittings.

5. With boom fully supported, remove and

discard bolts which secure mast to rotation

system. Upon reassembly, replace bolts

with new, properly-torqued bolts.

6. Remove rotation system from mounting

system.

3-9-2: SETTING BACKLASH - IMT BASE

& WORM DRIVE (1007, 1015, 2020)

NOTE

BACKLASH IS DEFINED AS THE SHORTEST

DISTANCE BETWEEN NON-DRIVING TOOTH

SURFACES OF ADJACENT TEETH IN MATING

GEARS. BACKLASH IS MEASURED AT THE

HIGH SPOT ON THE TURNTABLE BEARING

(USUALLY INDICATED BY YELLOW OR LIGHT

BLUE PAINT), USING A THICKNESS OR

FEELER GAUGE AT OR NEAR THE PITCH

DIAMETER AND TANGENT TO THE GEAR

TEETH.

Telescopic crane models 1007, 1015, and 2020

have a common gear and rotation system. To

set the backlash on these models,

1. Bolt the worm gear in place.

2. Position the high spot on the bearing next to

the center of the worm gear. (The high spot

on the bearing is marked by the manufac-

turer with paint.)

3. Screw a bolt into the threaded hole nearest

the high tooth. Screw additional bolts into

threaded holes at 90° from the high tooth.

4. Check for clearance between gears using a

feeler gauge. Clearance should be between

.005 and .012”. Rotate the gear completely

to verify that the assembly does not bind.

BACKLASH

ROOT

FILLET

PITCHLINE

TOPLAND

Figure C-3: Bearing Tooth Contact Point

Figure C-4: Pin and Indicator Tip

20030115

Loading...

Loading...