99903514:TELESCOPIC CRANE: 3-6 SECTION 3: REPAIR

To set the worm end play:

1. Locate the high tooth on the gear. (The high

spot on the bearing is marked by the manu-

facturer with paint.)

2. Screw a bolt into the threaded hole nearest

the high tooth. Screw additional bolts into

threaded holes at 90° from the high tooth.

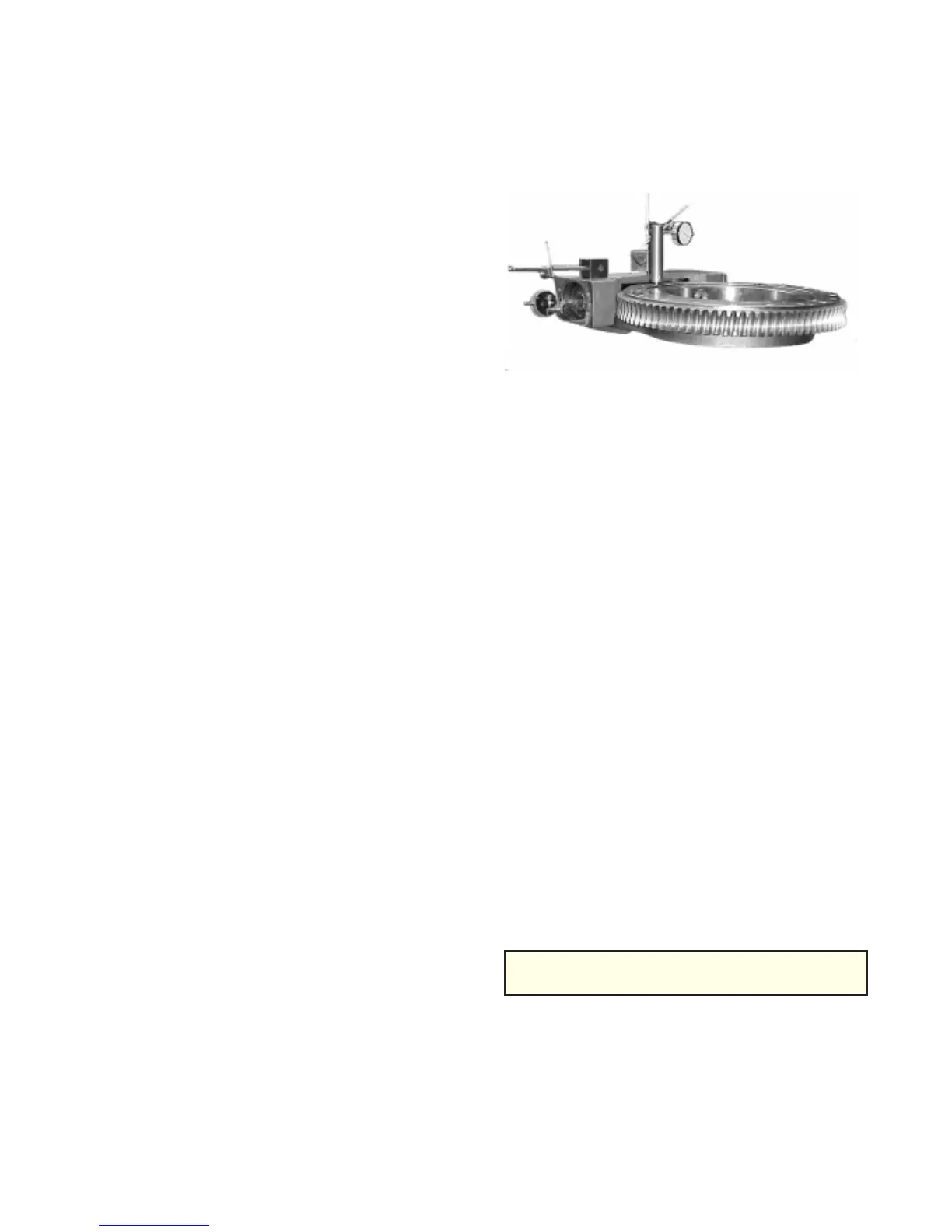

3. Mount a magnetic base with an indicator

attached on top of the worm housing and at

the opposite end from where the motor is

mounted.

4. Adjust the indicator to read from the end of

the worm shaft. Set the indicator to “0”.

5. Using two of the bolts as handles, rotate the

outer race back and forth. Read the total

indicator movement. The measurement is

the end play of the worm. The specification

for end play is +0.000/-0.004. If your end

play does not meet the specification, re-

move the bearing retainer and add or re-

move shims from the unit. Repeat the

measurement process until the end play

meets the specification.

To set the gear bearing backlash:

1. Locate the high tooth on the gear. (The high

spot on the bearing is marked by the manu-

facturer with paint.)

2. Rotate the bearing until the high tooth is

engaged with the worm. Loosen the three

bearing retaining allen head capscrews just

enough to be able to move the bearing

toward or away from the worm. Screw a

bolt into the threaded hole in the bearing

nearest the worm.

3. Set the magnetic indicator base on the

worm housing with the indicator probe

against the bolt, and set the indicator dial at

zero.

4. Move the bearing back and forth. Watch the

indicator dial, and adjust the bearing in or out

of the worm until the total indicator move-

ment is 0.005”. NOTE: Deduct any end play

inthe worm from the indicator reading.

5. Rotate the bearing 180°. Recheck the

backlash. Total backlash should be 0.005”

to 0.012”.

3-9-4: TURNTABLE GEAR REMOVAL &

REPLACEMENT (7020 & 7025)

Model 7020 and 7025 cranes are equipped with

a turntable gear. You can remove and replace

the entire gear assembly using a hoist, If a hoist

is not available, some boom disassembly will be

necessary.

1. Retract extension booms.

2. Operate LOWER and EXTENSION boom

control levers to position outer boom verti-

cally with the boom point as low as possible.

3. Place two fabric slings around the boom.

Cinch on opposite sides of the boom center

of gravity. Hook slings on hoist and raise

hoist to tension the slings.

4. Identify, mark and remove hose connections

between the crane base and boom. Cap or

plug all open hydraulic fittings.

5. With base, mast, and boom fully supported,

remove bolts which secure mast to turntable

gear.

CAUTION

DO NOT LIFT CRANE TOO QUICKLY.

HOSE DAMAGE MAY OCCUR.

7. Turntable gear bearing is now exposed.

Remove cap screws that secure turntable

gear to crane base.

8. Remove turntable gear from crane base.

Figure C-5: Dial Indicator Set-up

6. After setting the backlash, torque the bearing

retaining allen head capscrews which

watching the indicator dial so that the cor-

rect backlash setting is maintained.

20030115

Loading...

Loading...