99903514:TELESCOPIC CRANE: 3-7 SECTION 3: REPAIR

9. Thoroughly clean the top of the crane base

and bottom of the new turntable gear bear-

ing. The mating surfaces must be clean

and dry - no oil or grease.

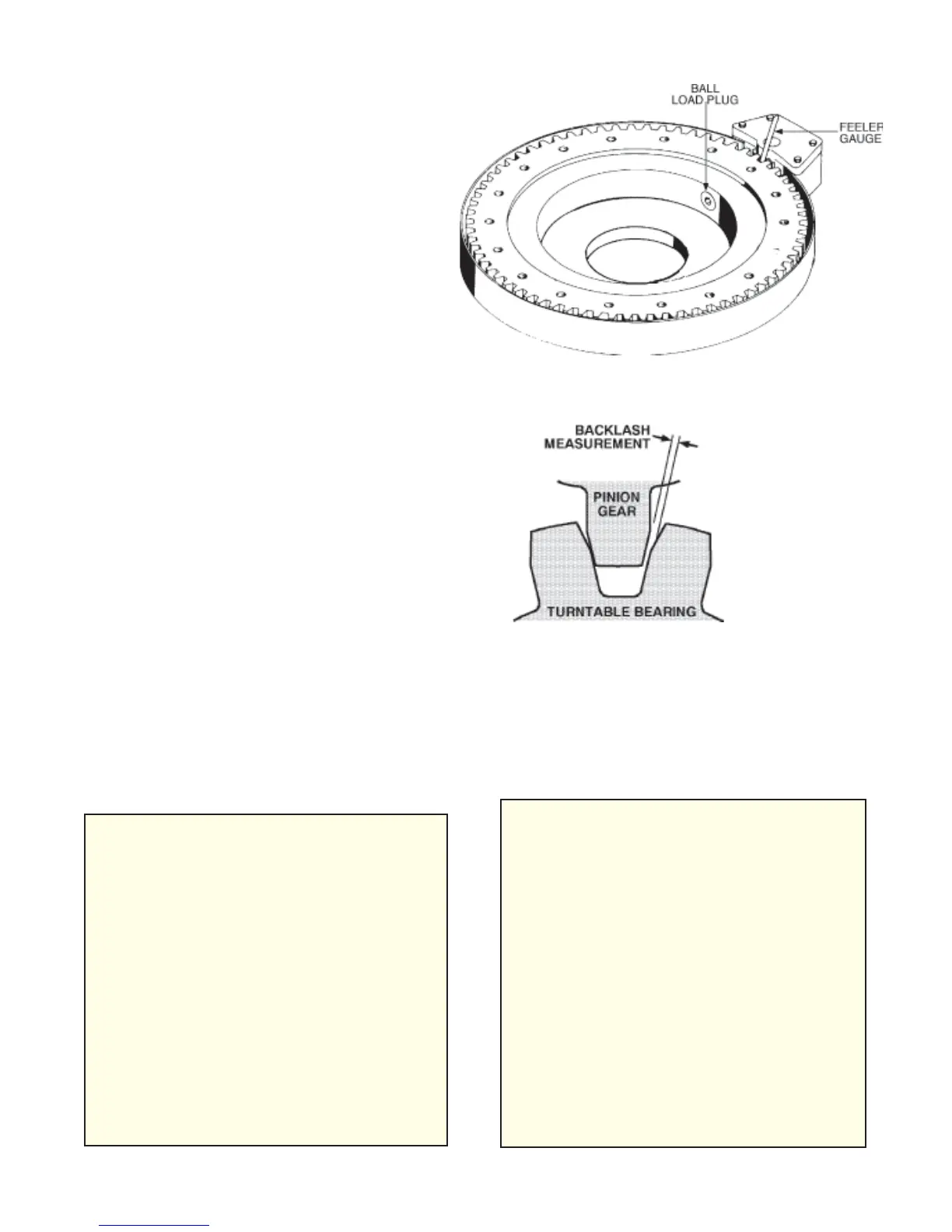

10. Install the new gear bearing, with ball loading

plug located next to pinion gear (See Figure

C-6), using new bolts, hardened flat wash-

ers and Loctite 262 or an equivalent thread

lock on bolt threads. Torque all cap screws

per Torque Data Charts in the general

reference section.

11. Reverse procedure for reassembly. Use

new cap screws and hardened washers

when attaching mast to turntable gear.

Torque cap screws per Torque Data Charts

in the general reference section.

12. Start the unit and slowly cycle all of the

controls to evacuate air trapped in the

hydraulic system. Simultaneously check for

leaks.

13. After air has been purged from the system,

check the reservoir oil level and top off oil if

necessary.

14. Lift the full rated load and swing it completely

around in both directions. Actuate the

controls very slowly and keep the load as

close to the ground as possible. Set the

load down and move the crane to the stored

position.

15. Recheck the gear bearing bolt torque of all

gear bearing mounting bolts.

Figure C-6: Turntable Gear Bearing

Installation

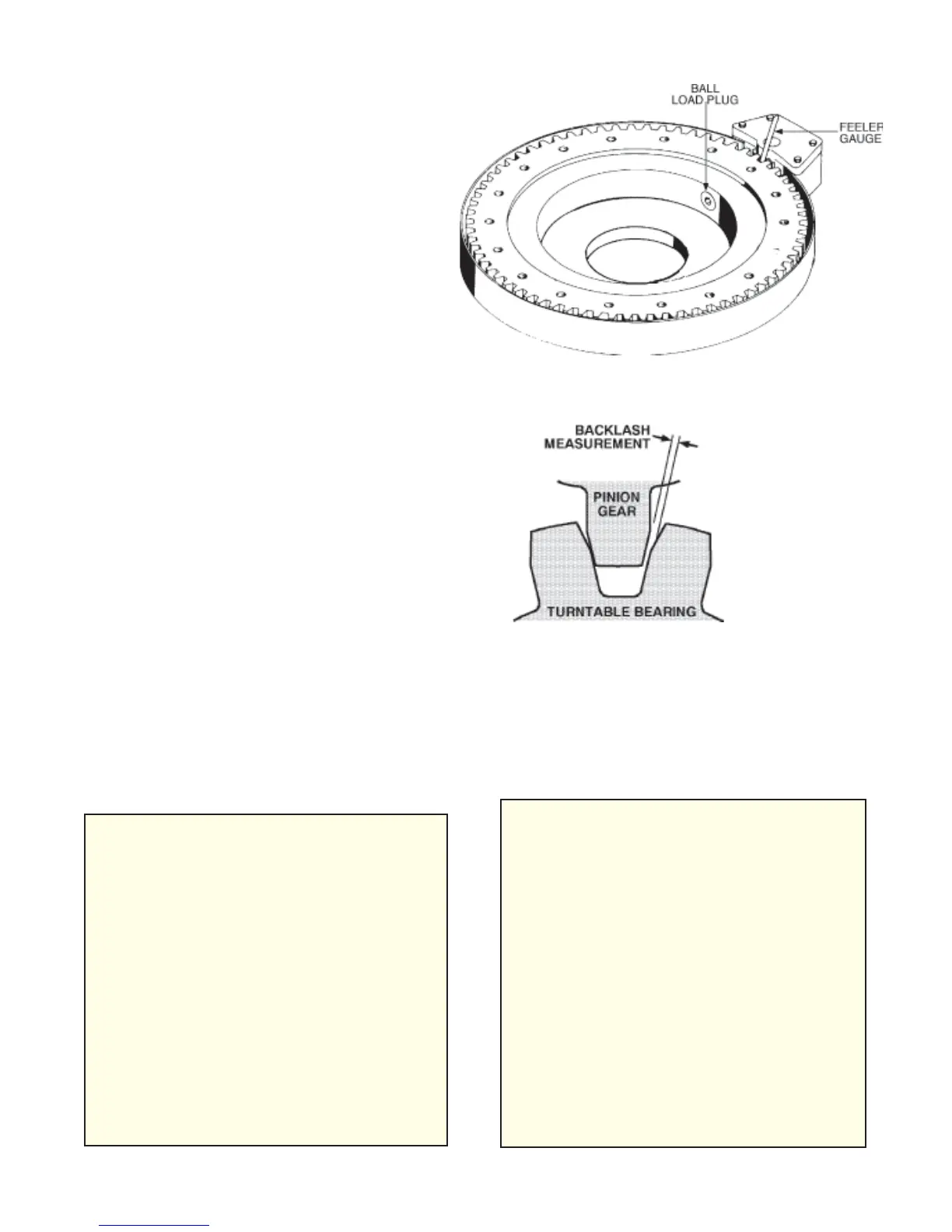

Figure C-7: Turntable Gear Bearing

Backlash Measurement

WARNING

AFTER REMOVAL, REPLACE ALL GEAR

BEARING MOUNTING BOLTS WITH IDEN-

TICAL, NEW BOLTS. FAILURE TO RE-

PLACE GEAR BEARING BOLTS MAY

RESULT IN BOLT FAILURE DUE TO

METAL FATIGUE AND COULD CAUSE A

SERIOUS INJURY OR DEATH.

BEFORE TORQUING, SEE TURNTABLE

BEARING FASTENER TIGHTENING SE-

QUENCE IN THE REFERENCE SECTION.

CHECK ALL BOLTS AFTER SWINGING

THE FULL RATED LOAD. APPLYING THE

FULL LOAD AGAINST ALL OF THE BOLTS

WILL TEST BOLT TORQUES.

NOTE

FOR PROPER OPERATION OF THE

CRANE, THE HIGH SPOT ON THE TURN-

TABLE GEAR MUST BE MATCHED TO

THE PINION GEAR. THE HIGH SPOT ON

THE TURNTABLE GEAR IS NORMALLY

MARKED WITH YELLOW OR LIGHT BLUE

PAINT. REMOVE PAINT AND CHECK

GEAR BACKLASH WITH A FEELER

GAUGE. CLEARANCE BETWEEN PINION

GEAR AND TURNTABLE GEAR BEARING

TEETH WILL USUALLY BE LISTED ON

THE BASE ASSEMBLY DRAWING IN THE

PARTS SECTION OF YOUR SPECIFIC

CRANE MANUAL. SHIFT THE TURN-

TABLE GEAR AROUND TO ADJUST THE

BACKLASH. SEE FIGURE C-7 FOR BACK-

LASH INFORMATION.

20030115

Loading...

Loading...