99903514:TELESCOPIC CRANE: 3A-2

SECTION 3A: CYLINDER REPAIR

20120521

TOOLS REQUIRED

Use the following tools in the disassembly and repair

of IMT cylinders:

PLASTIC AWL

FOR SEAL REMOVAL AND REPLACEMENT.

PLASTIC/RUBBER HAMMER

USED TO REMOVE STOP TUBE RING FROM

ROD.

SPANNER WRENCH ATTACHMENT

ATTACH TO A STANDARD TORQUE WRENCH

TO TORQUE OR REMOVE CYLINDER HEADS

AND PISTONS. SEE CHART AT END OF

SECTION TO SELECT ATTACHMENT FOR

YOUR PARTICULAR CRANE.

O-RING / ROD SEAL INSTALLATION TOOL

USED TO INSTALL / REMOVE O-RINGS &

SEALS. MEASURE ROD DIA. TO SELECT

CORRECT TOOL.

IMT PART # ROD DIA.

79075110 0.75 - 1.5 “

79075111 1.5 - 2-0"

79075112 2.0 - 3.0"

WARNING

REPLACE ALL SEALS WHENEVER THE CYLINDER

IS DISASSEMBLED. FAILURE TO DO SO CAN

CAUSE DEATH, SERIOUS INJURY OR EQUIPMENT

DAMAGE. REFER TO CRANE PARTS MANUAL

FOR CYLINDER SEAL KIT PART NUMBERS.

WARNING

FLAMMABLE CLEANING SOLVENTS POSE FIRE

AND HEALTH HAZARDS. READ AND OBEY THE

INSTRUCTIONS ACCOMPANYING ANY SOLVENTS.

KEEP A SUITABLE FIRE EXTINGUISHER PRESENT

WHENEVER USING FLAMMABLE SOLVENTS.

USE SOLVENTS IN A WELL VENTILATED AREA.

IGNORING THESE WARNINGS WILL CAUSE

SERIOUS INJURY OR DEATH. IMT RECOMMENDS

USING AN ALKALINE CLEANER.

WARNING

DO NOT USE COMPRESSED AIR TO ASSIST IN

WITHDRAWING THE PISTON/ROD ASSEMBLY.

COMPRESSED AIR MAY PROPEL THE PISTON/

ROD ASSEMBLY OUT OF THE CYLINDER AND MAY

CAUSE SERIOUS INJURY OR DEATH.

CAUTION

WHEN SOLVENT IS USED TO CLEAN THE

INTERNAL CYLINDER COMPONENTS, ALL TRACES

OF SOLVENT MUST BE REMOVED. ANY RESIDUE

WILL DAMAGE THE SEALS.

3A-1. CYLINDER DISASSEMBLY

These instructions apply to inner, outer, extension and

stabilizer cylinders.

1. Thoroughly wash the exterior of the cylinder case.

Blow dry with compressed air. Avoid lodging chunks of

material in oil passages.

NOTE

AFTER THE CASE HAS BEEN WASHED, PROCEED

WITH DISASSEMBLY IN A CLEAN ENVIRONMENT

WHICH IS FREE OF DUST AND DIRT.

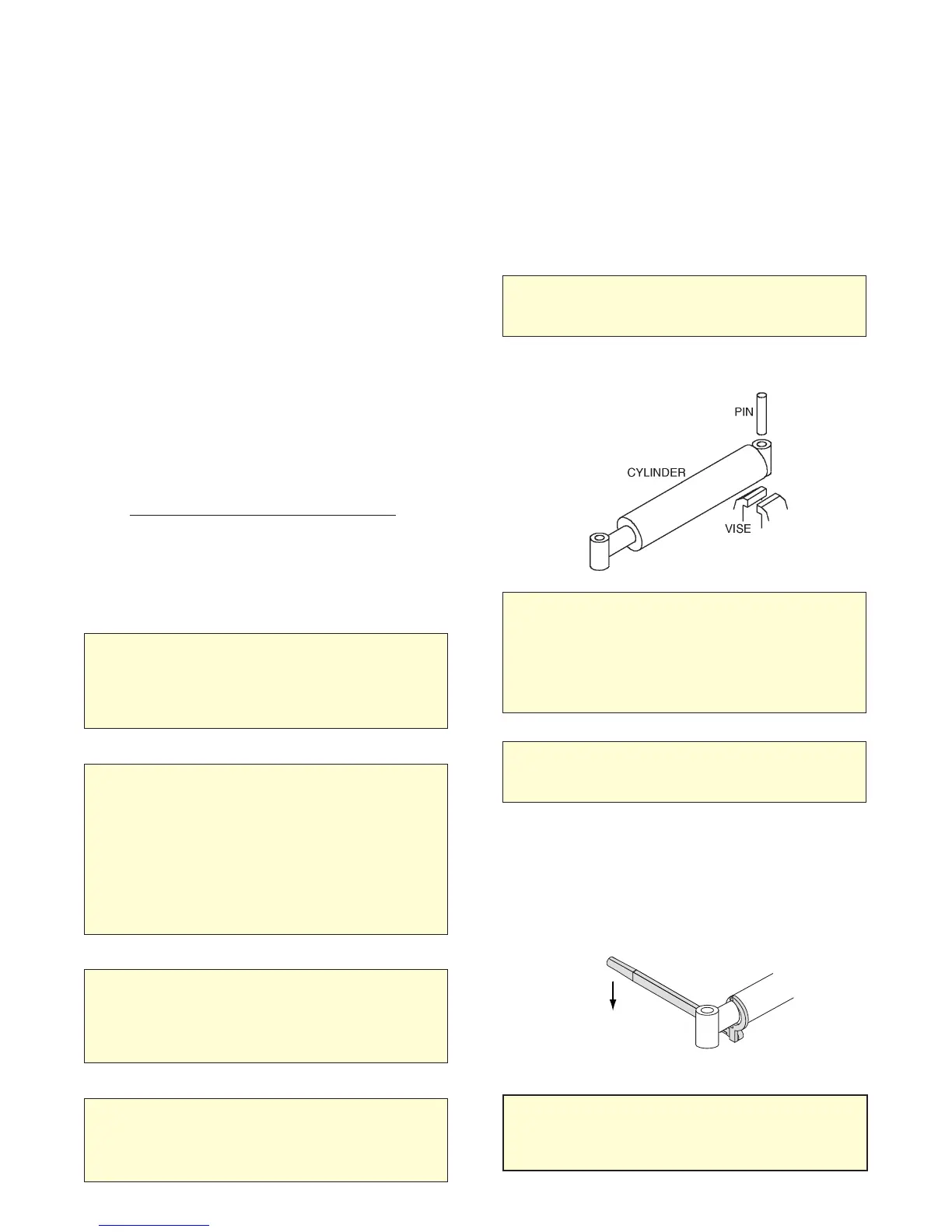

2. Place the cylinder on a flat surface near a vise.

Slip a pin through the pin boss and clamp the pin in a

vise.

WARNING

RELEASE PRESSURE ON THE CYLINDER. FOR

CYLINDERS WITH HOLDING VALVES, SLOWLY

UNSCREW VALVES UNTIL PRESSURE IS

RELIEVED, THEN REMOVE VALVE. FOR

CYLINDERS WITHOUT HOLDING VALVES, SLOWLY

REMOVE PLUGS OR CAPS.

CAUTION

CLAMP ONLY THE PIN. DO NOT CLAMP THE

CYLINDER IN A VISE. DOING SO WILL DAMAGE

THE CYLINDER.

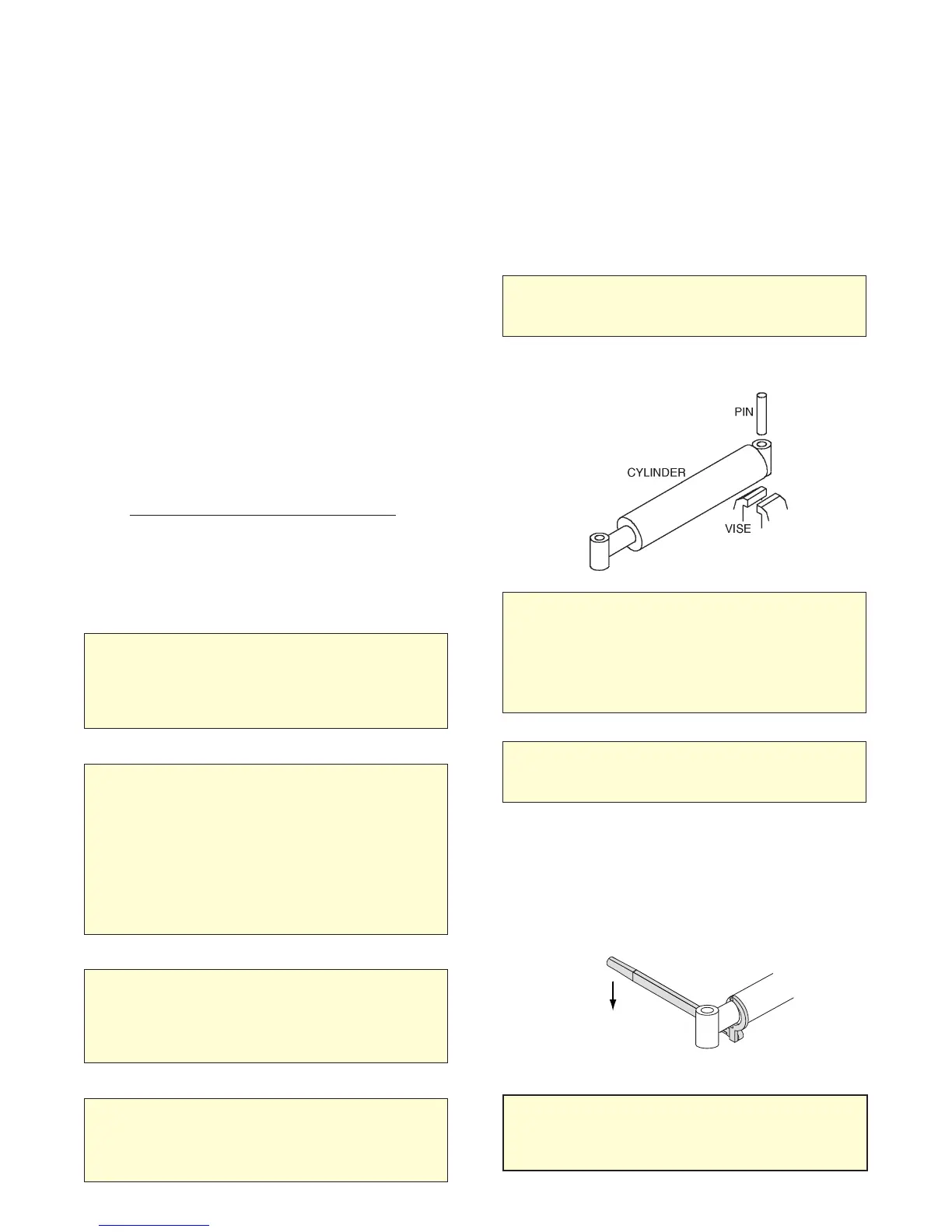

3. Using a spanner wrench, unscrew the head.

Withdraw the head from the cylinder case. Pull the

rod and piston assembly from the cylinder case using

an up-and-down or side-to-side motion. Set the

cylinder case to one side.

HEAD

SPANNER

WRENCH

TO

REMOVE

HEAD

CAUTION:

DO NOT USE A PIPE WRENCH TO TIGHTEN OR

LOOSEN THE HEADS. IT WILL DEFORM THE

METAL, DAMAGE THE MATING SURFACES, AND

PREVENT PROPER TORQUE MEASUREMENT.

Loading...

Loading...