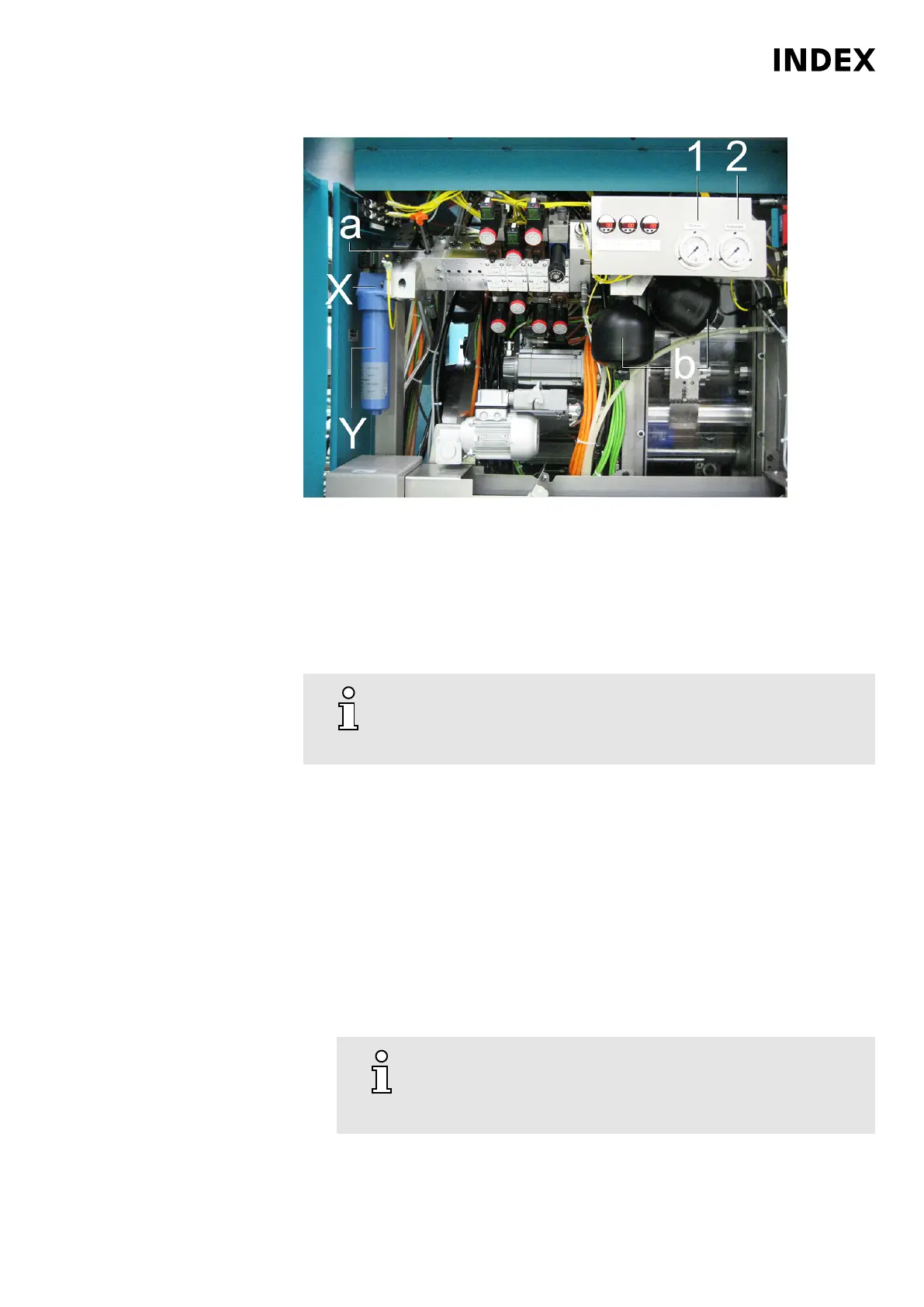

Example: Hydraulic unit MS40-8

a

Accumulator drain valve

b Pressure accumulator

1 Pressure gauge for system pressure

2 Hydrostatic pressure gauge

X Hydraulic fluid filter

Y Filter bowl

Requirement

Depressurize the hydraulic and lubrication systems by opening the

accumulator drain valve.

Power off the machine and secure it against accidental power on.

The maintenance of the lubricating oil supply requires the following auxiliary or

working equipment:

- servicing, testing and maintenance schedules/logs of the customer.

- Use an ample supply of cleaning rags – no cotton waste.

- A sufficient amount of hydraulic fluid or lubricating oil. - Oil type, specification

and quantity as specified in the technical data.

- To avoid impurities in the hydraulic system, pre-filter the oil to be refilled

with 3µ.

- Replacement filters. – Use only original filters.

- Various sizes of jaw and box wrenches, and Allen keys.

Procedure

1.

The hydraulic fluid and lubricating oil levels should always be

near the top mark when the machine is switched off. During

production, the oil level may drop after several consumers have

been connected.

Check oil level at the oil sight glass.

Maintenance Summary - Care activities

13

Maintenance Instructions

MS40-8

DIM078EN - 02.06.2020

Loading...

Loading...