If the installation dimension is not correct, turn the base body forward or

backward, until the setting dimension is achieved. Observe the installation

position.

7.

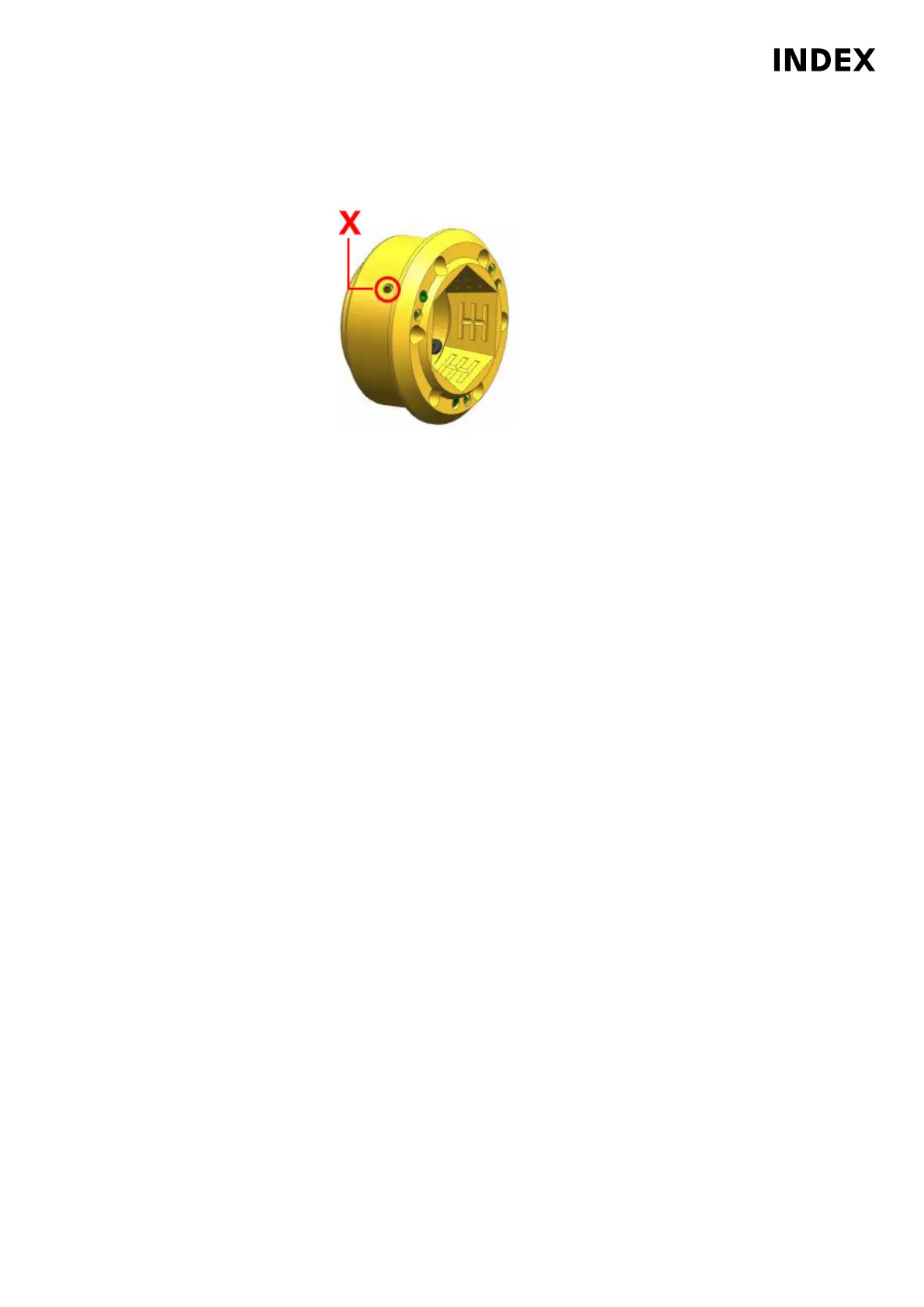

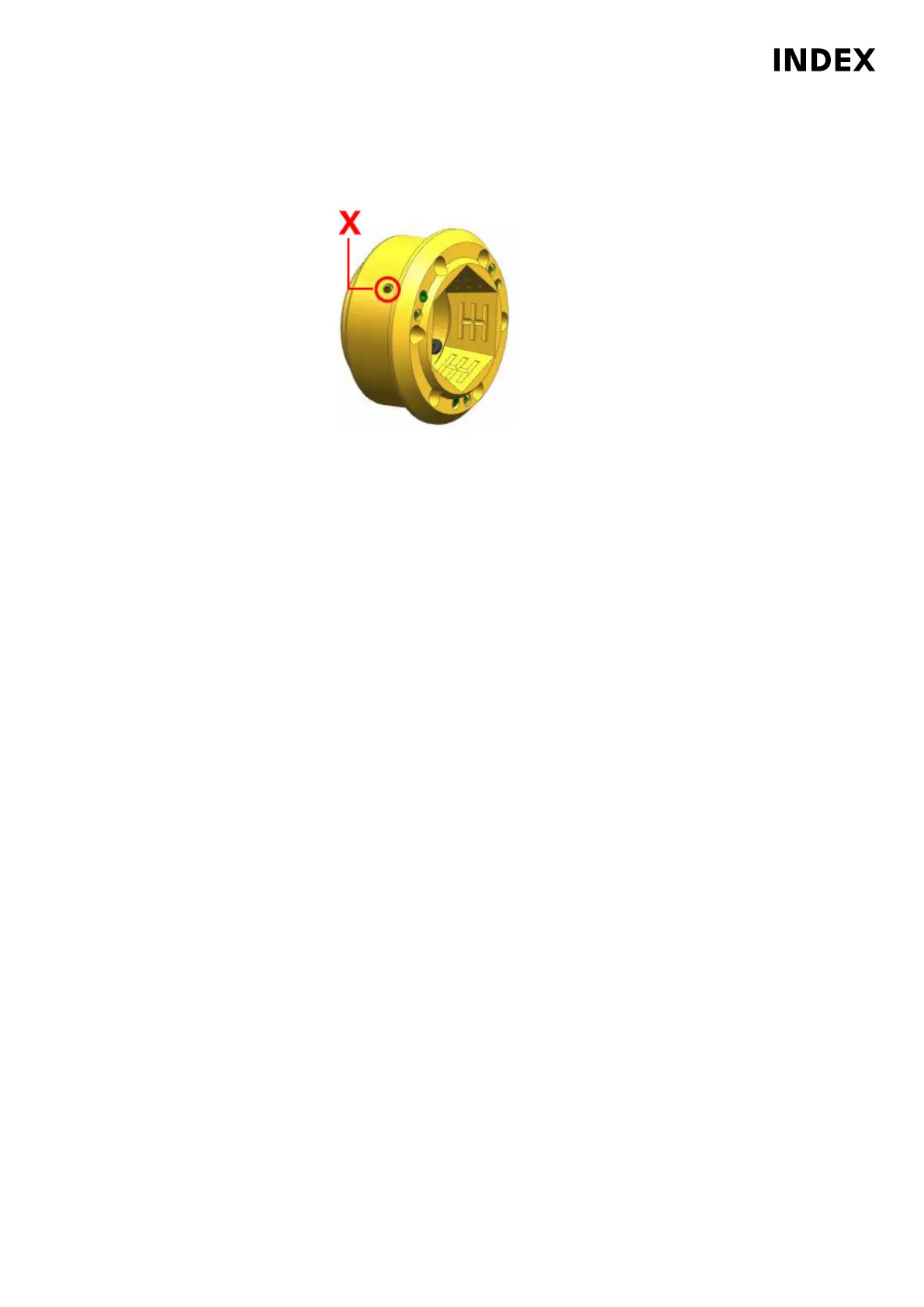

Example: Close TOPlus on cooling lubricant device through main spindle

X

Bonded (Loctite

®

221) set screw

Check the clamping element holder. Valid for all machines MS32-6.3, MS40-6

and MS40-8 with TOPlus clamping system, robot and cooling lubricant device

through the main spindle. Before reinstalling the clamping element holder,

make absolutely sure that the holes marked X are closed with set screws. The

set screws must be screwed down to the bottom of the hole and bonded with

Loctite

®

221.

8. Place the clamping element holder (2) on the spindle nose face (5) and screw

in 6 screws.

9. Tighten the 6 screws (3) crosswise to a torque of 14.9 Nm.

10. Insert collet (4).

11. Be sure to remove the spindle lock (device/locking pin) after finishing

the work.

Maintenance Summary - Care activities

43

Maintenance Instructions

MS40-8

DIM078EN - 02.06.2020

Loading...

Loading...