CM140 - Inspection of the pneumatic system

Orientation

Operating fluids such as hydraulic fluids, cooling lubricants, lubricating greases/oils

are also subject to degradation or aging as the components involved in this process,

and must therefore be serviced, refilled or replaced at regular intervals.

To ensure trouble-free operation, periodic checks of the pneumatic system are

necessary.

- Check pressure setting on pressure gauge.

- Check fluid lines.

- Check silencers.

- Drain off condensate.

- Check filters, replace if necessary.

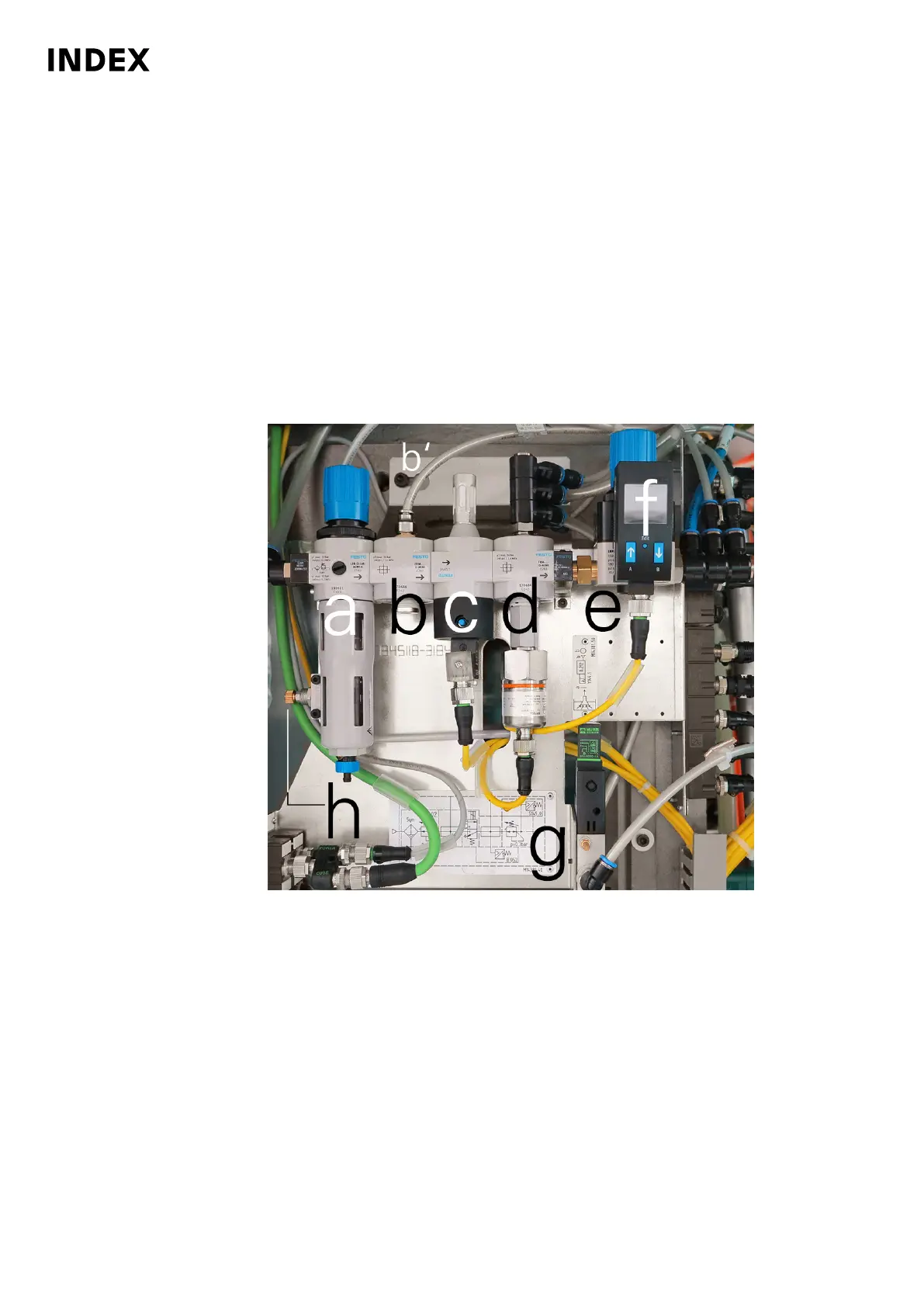

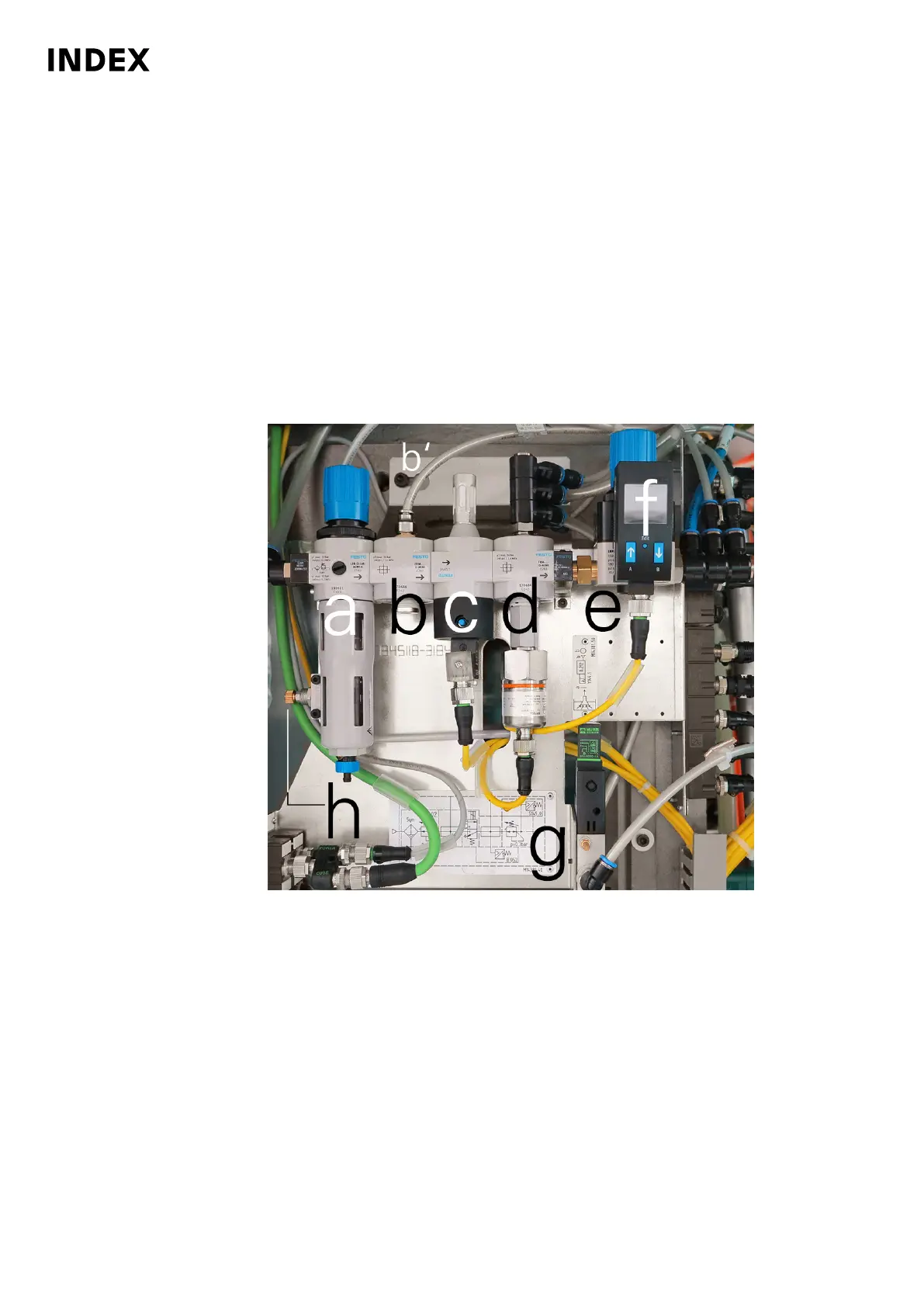

Example: Pneumatic maintenance unit by Festo

a

Filter regulating valve (factory set to 6 bar)

b Branch module

b’ Branch fire shutter

c

Switch-on valve (electrically operated) with silencer

(*)

.

d Branch module with pressure monitoring (factory set to min. 4.0 bar)

e High-precision pressure regulating valve (factory set to 0.3 bar)

f Pressure sensor

g Suction pump switching valve

h Throttle for fire protection sensor

( * ) Check by manually pushing (using a ballpoint pen or similar) the blue button of

the switch-on valve (manual auxiliary operation).

Maintenance Summary - 2.000 Operating hours

60

Maintenance Instructions

MS40-8

DIM078EN - 02.06.2020

Loading...

Loading...