20

5 Operation and Maintenance

5.1 Start and Shutdown

After writing a program to the PLC, take the following steps to start or shut down

the PLC.

After writing a program to the PLC in the STOP state, start the system as follows:

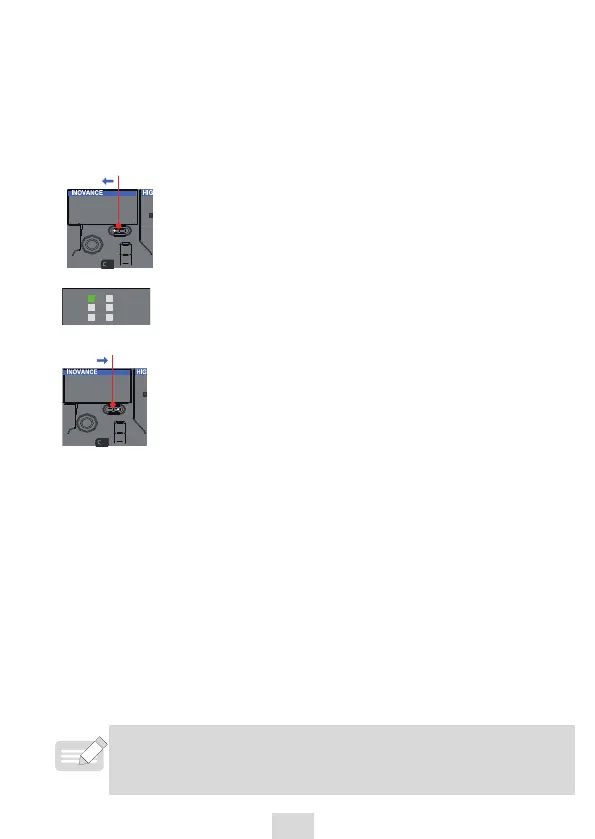

MFK

RUN/

STOP

1. Set the RUN/STOP switch to RUN.

RUN

ERR

BAT

BF

CANRUN

CANERR

2. Check that the RUN indicator is steady ON in green.

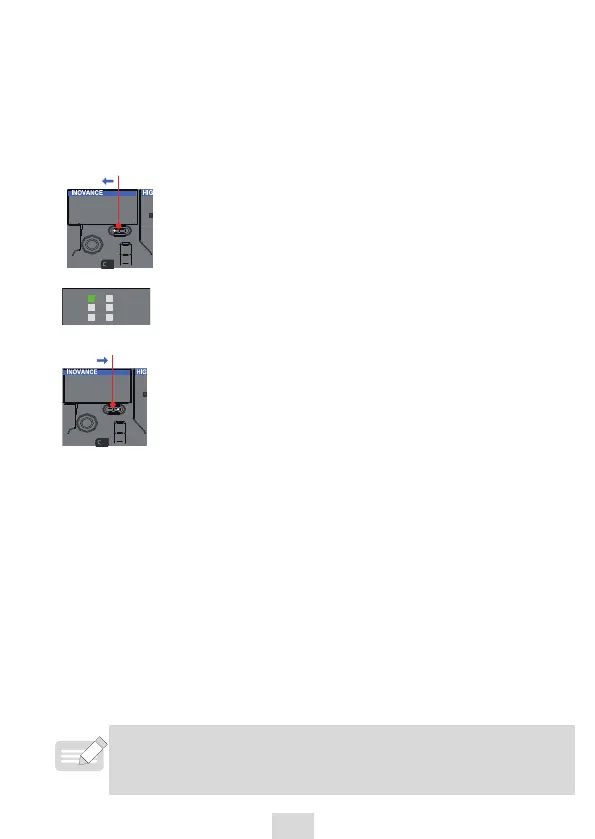

MFK

RUN/

STOP

3. To stop the system, set the RUN/STOP switch to STOP.

Alternatively, you can stop the system in the software tool

of the host controller.

5.2 Spare Battery Maintenance

The PLC provides a spare battery for RTC timing.

1) The clock stops timing if no battery is installed or the battery is being

discharged.

2) The maximum battery life is ve years, depending on the specic use

environment. Replace the battery once the battery level drops to zero.

● Battery replacement

1) Set the PLC's RUN/STOP switch to STOP to cut o the power supply.

2) Open the cover of the battery and DIP switch compartment, and take out the

battery with a pair of tweezers or a proper jig.

3) Push a new battery into the compartment and close the cover.

4) Lithium batteries needs to be replaced by a professional.

It is recommended that the battery be replaced while the power supply is

connected. If the PLC has been powered o, insert a new battery within 30s

after the old battery is removed to ensure correct RTC timing.

Loading...

Loading...