Chapter: Maintenance

114 M10-17318-EN

• Guide columns - The guide columns require only a thin film of lubrication. It is

recommended that the machine be re-lubricated every two years.

The guide column is located behind the ballscrew. If you suspect that the guide

column needs lubrication, contact Instron

®

Service for assistance.

The top and bottom ballscrew bearings are sealed and should never need lubrication.

Lubricate ballnuts

Refer to Figure 25 on page 115.

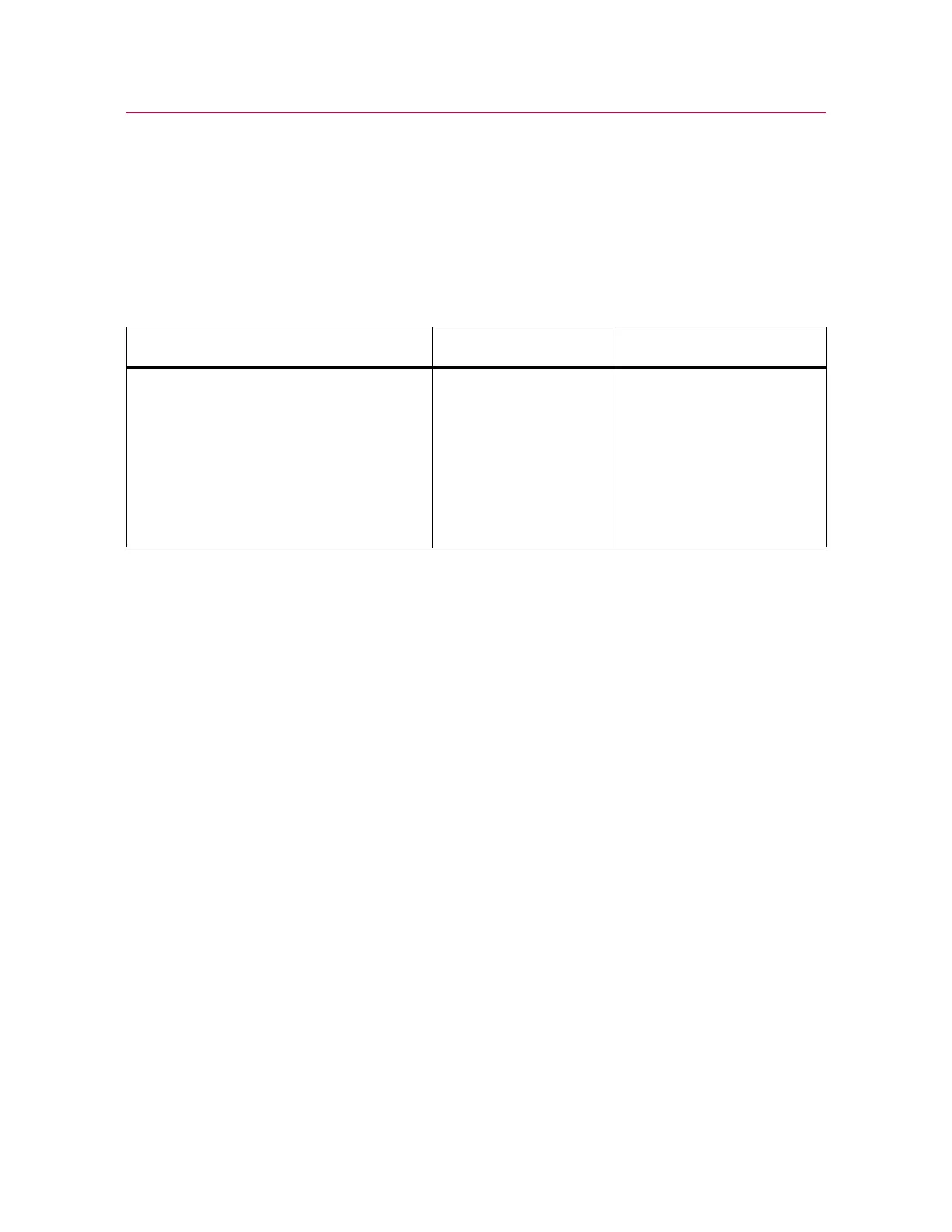

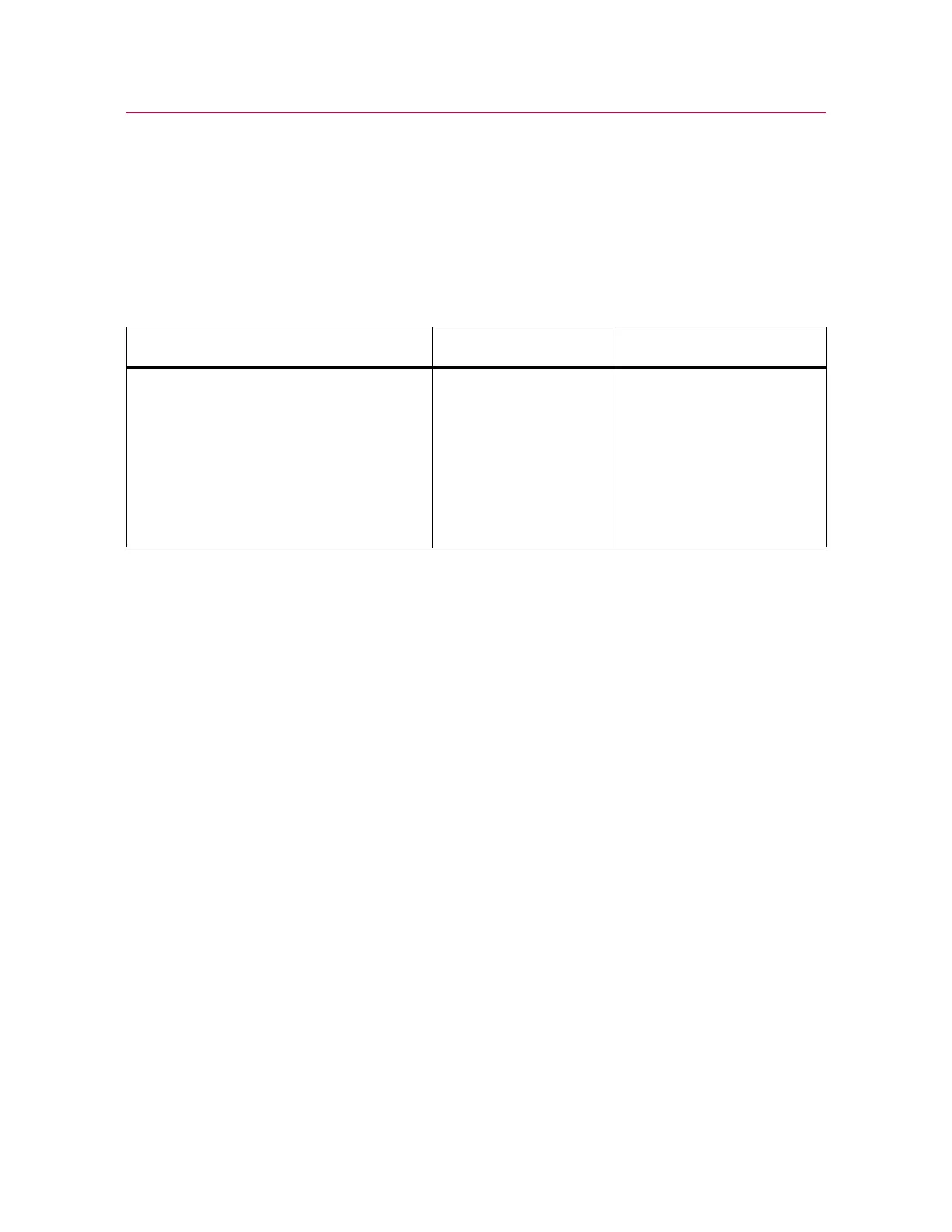

Table 9. Lubrication Requirements for Ballnuts

Recommended Lubricant Interval Instron

®

Part Number

Lithium based water resisting grease -

NLGI Class 2

(DIN51825 class K2k LS2)

Equivalents:

Lubriplate: Lubriplate 1200-2

Mobil: Mobilux® 2

BP: Energrease® LS2

Shell: Alvania® R2

1000

1

hours or 36

months of

operating time

2

105-1-1057

(small can of lubricant)

1. If the system is used more than 100 hours per month, inspect the lubricated area periodically and

increase lubrication frequency as required.

2. Operating time is defined as time of crosshead movement, not the length of time the system has been

powered on.

Loading...

Loading...