Instruction Manual CVM201 Super Bee

InstruTech, Inc. Page 27

9 Service

9.1 Calibration

Every InstruTech module is calibrated prior to shipment using nitrogen (N

2

). However, you can calibrate the instrument by

adjusting zero (vacuum) and span (atmosphere) using the procedure described previously in section 4.2 titled

“Programming”. Zero and span (atmosphere) calibration affect the displayed value and the output signal. Zero calibration

optimizes performance of the gauge when operating at a low pressure range of 1 x 10

-4

Torr to 1 x 10

-3

Torr. If your

minimum operating pressure is higher than 1 x 10

-3

Torr, it is not normally necessary to perform calibration at zero and thus

span calibration should be adequate. If you are able to evacuate your system to below 1 x 10

-4

Torr, it is always a good

practice to check and set zero if necessary. This will also improve performance in cases where gauge contamination is

causing higher readings than 1 x 10

-4

Torr even though the system has been evacuated to below

1 x 10

-4

Torr. Care should be exercised when using gases other than nitrogen (N

2

).

9.2 Maintenance

In general, maintenance is not required for your InstruTech module. Periodic performance checks may be done by

comparing the gauge to a known reference standard.

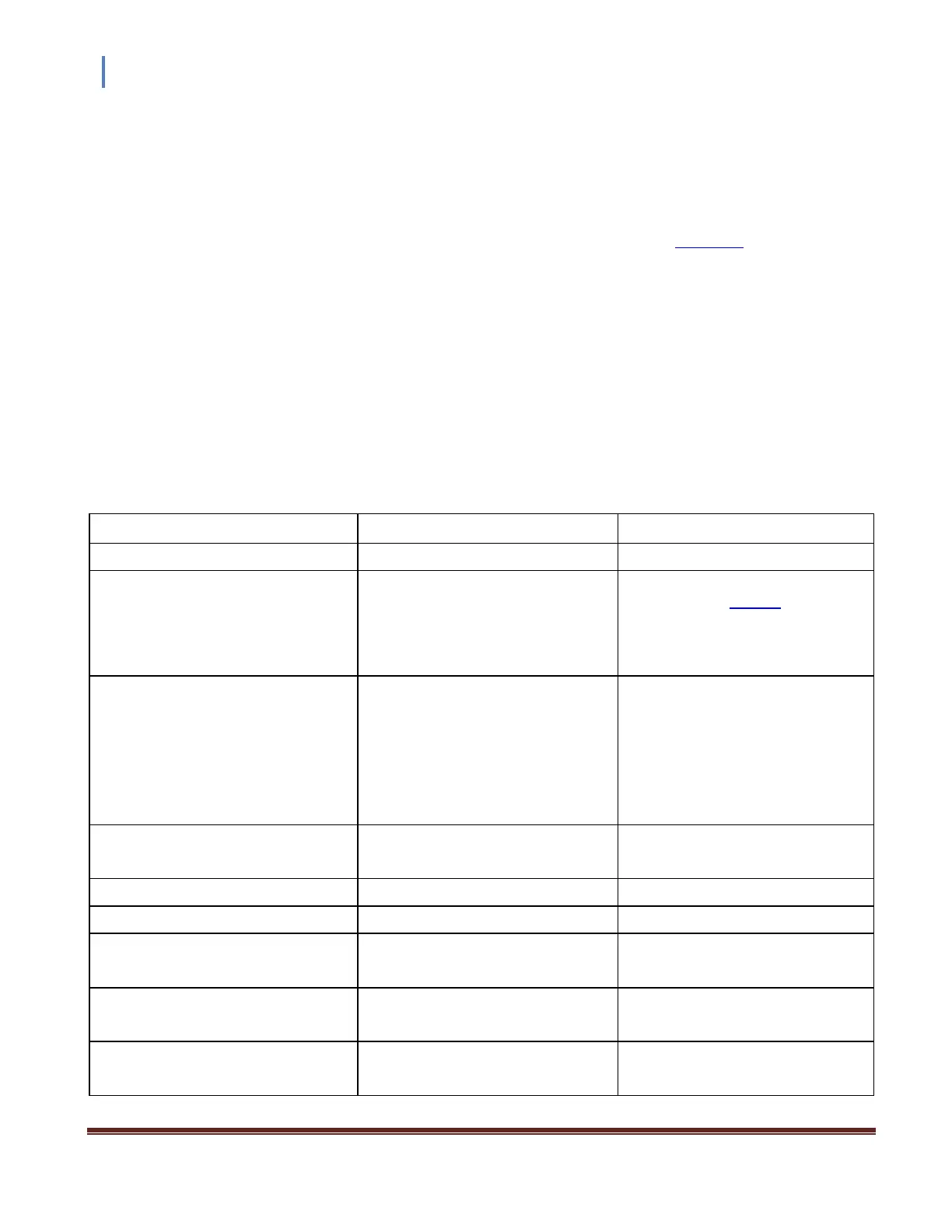

9.3 Troubleshooting

Check power supply & power cable

Readings appear very different from

expected pressure

The process gas is different from the gas

used to calibrate the CVM201

Correct readings for different gas thermal

conductivity. See section 5 on using the

gauge with different gases

Module has not been calibrated or has

been calibrated incorrectly

Check that zero and span are adjusted

correctly

Readings are noisy or erratic

Loose cables or connections

Check and tighten connections

Inspect gauge for signs of contamination

such as particles, deposits, discoloration

on gauge inlet. Return to factory for

possible cleaning

Ensure gauge is not mounted where

excessive vibration is present

Gauge cannot be calibrated - zero and span

can’t be adjusted

Contamination

Sensor failure for other cause

Return to factory for possible cleaning

Replace sensor inside CVM201 module

Setpoint does not actuate

Display shows “Sensor Bad”

Replace sensor inside CVM201 module

Display shows “overpressure”

System pressure over 1000 Torr

Faulty electronics

Reduce pressure

Repair or replace CVM201 electronics

Atmospheric pressure reads too high and

can’t be set to correct value

Contamination

Sensor wire damaged

Return to factory for possible cleaning

Replace sensor inside CVM201 module

Atmospheric pressure reads too low and

can’t be set to correct value

Sensor wire damaged

Contamination

Replace sensor inside CVM201 module

Return to factory for possible cleaning

Loading...

Loading...