IntelliTech International, Inc. Programmer’s Guide | 1

29 Thermal Printer Programmer’s Guide

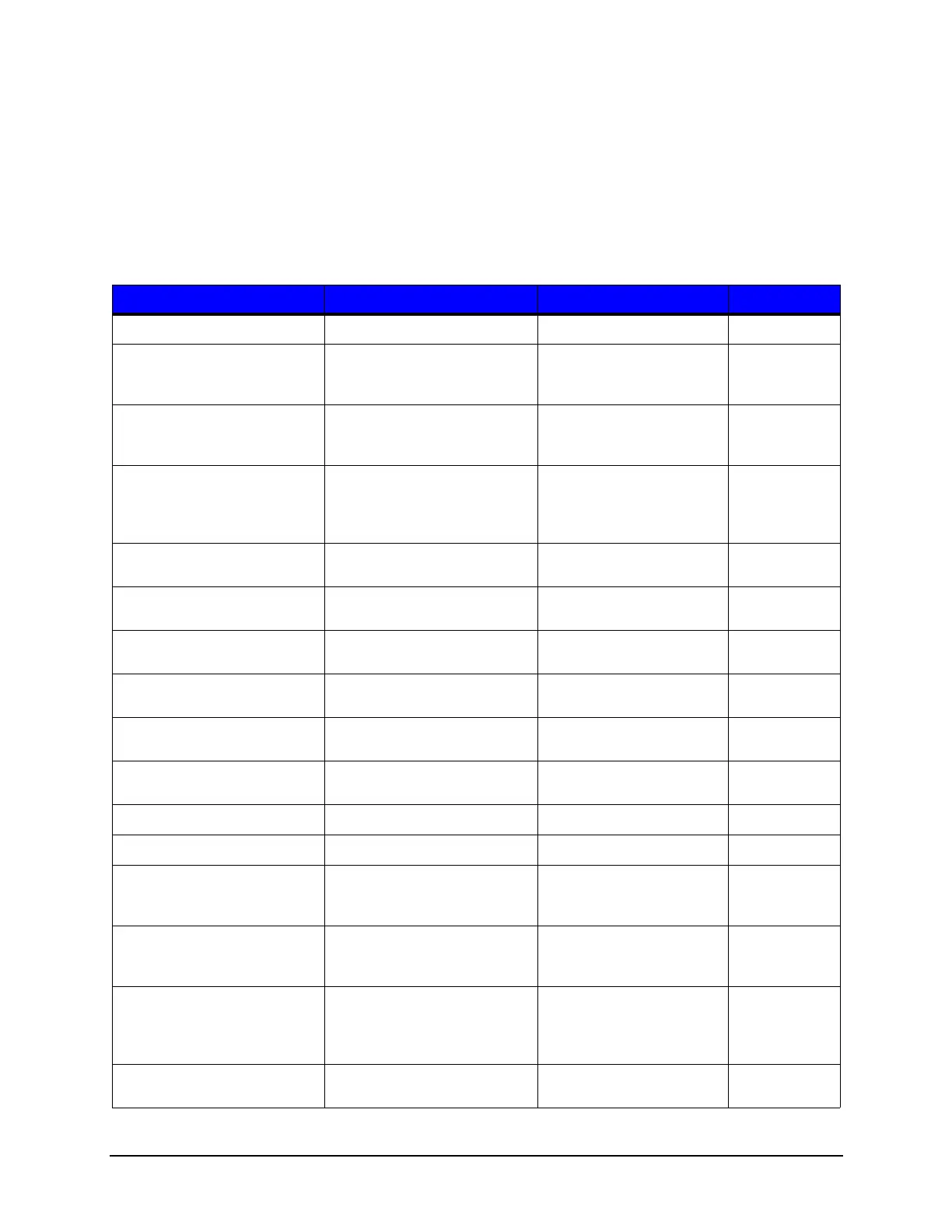

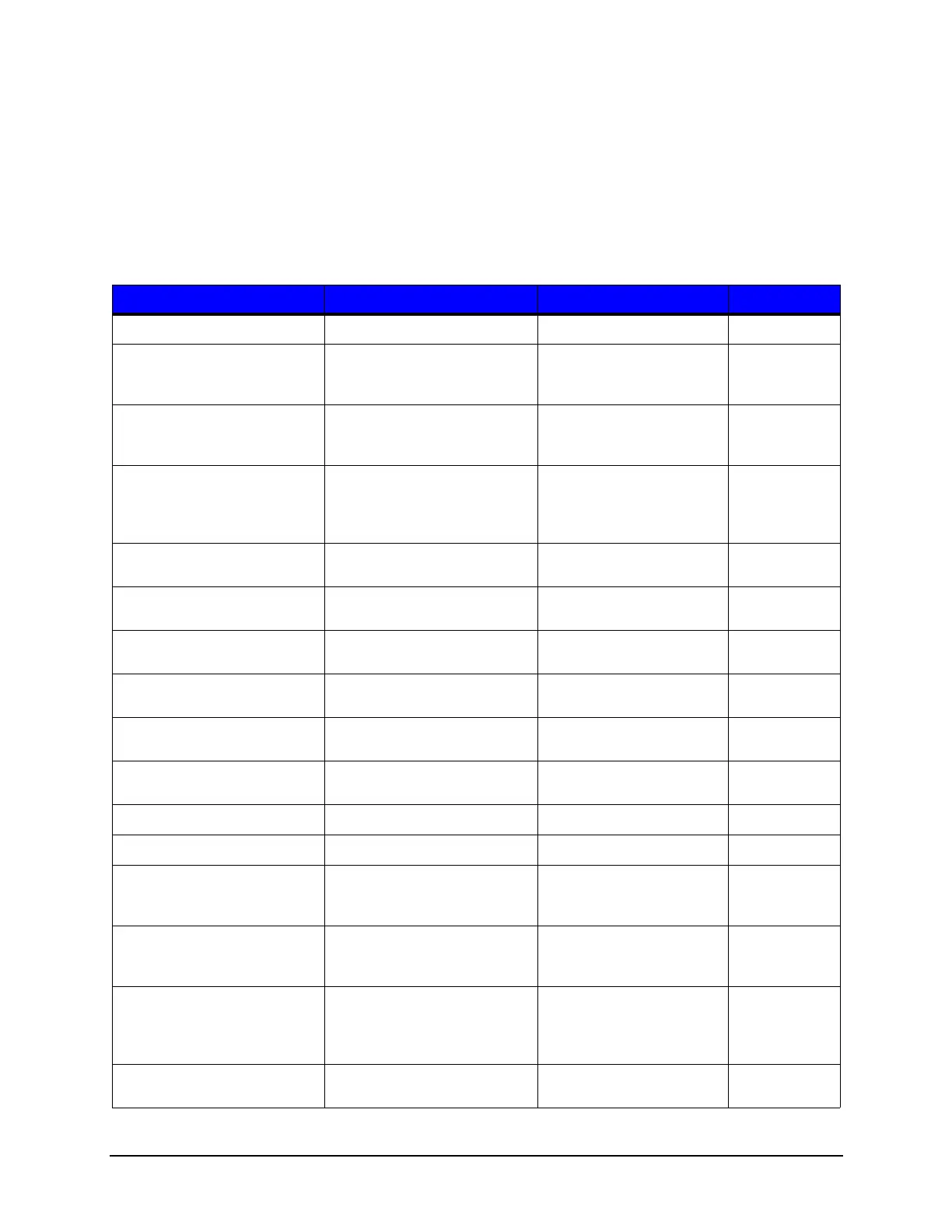

PJL Variables

The PJL variables supported by the printer include some standard as well as custom

variables. The DEFAULT command allows the user to set a variable permanently,

however this should never appear in a configuration header for a PCL print job. Only a

few select parameters can use the SET command in a PCL print job.

Table 13: PJL Variables

Variable Description Range Default

HEAT

6, 7

Controls the heat energy 1 – 30 4

HEATBALANCE

6, 7

Controls the energy of the

leading edges of the printed

image

1 – 10 7

HEADPRESSURE

6

Adjusts the printer head

pressure to enhance the quality

of print

1 - 10 7

PAPERSENSORTYPE

6

Specifies the type of mark used

to indicate the top of a label.

NONE implies continuous.

NONE, GAP,

MARKTOPSIDE,

MARKUNDERSIDE,

NOTCH

GAP

PAPERSENSORSIDE

6

Specifies which media sensor to

use

INSIDE, OUTSIDE OUTSIDE

RIBBON

6

Specifies thermal transfer (TT)

or direct thermal (DT)

NONE, INSIDE, OUTSIDE INSIDE

RIBBONLOWDIAMETER The diameter at which a ribbon

low warning will be triggered

100 - 2000 (1/1000") 1380

RIBBONTENSIONF

6

This sets tension of the front

ribbon motor

1 - 30 20

RIBBONTENSIONR

6

This sets tension of the rear

ribbon motor

1 - 20 15

REWINDTENSION

6

This sets tension of the rewinder

motor

1 - 20 11

PAPERID

6

Paper ID code "XG04"

RIBBONID

6

Ribbon ID code "YI02"

KEYPROMPT Informs the user interface to

prompt the user for the next

label

OFF, ON OFF

CUTTER

7

When a cutter is installed, this

controls the cutting action for the

media

OFF, PERLABEL OFF

REWINDER When the rewinder is installed,

this controls the operation and

direction of the powered internal

label rewinder

OFF, CLOCKWISE,

COUNTERCLOCKWISE

OFF

PRESENTSENSOR This controls the "on-demand"

dispensing of labels

OFF, ON OFF

Loading...

Loading...