95

Matrix Mono

Part 3 - Installaon and Field Sengs

Matrix Mono

94

Inventor Matrix Mono Engineering Data Book

Ta-adj is an correction value for Ta.

SOLAR INPUT sets whether solar control signal is connected to hydronic PCB.

(0=NON; 1=CN18; Tsolar 2=CN11SL1SL2)

F-PIPE LENGTH sets the length of refrigerant pipes between outdoor unit and indoor unit.

RT/Ta_PCB sets whether M-kit is valid.

Pump silent mode can decrease water pump maximum output by 5% in order to decrease the noise of heat pump.

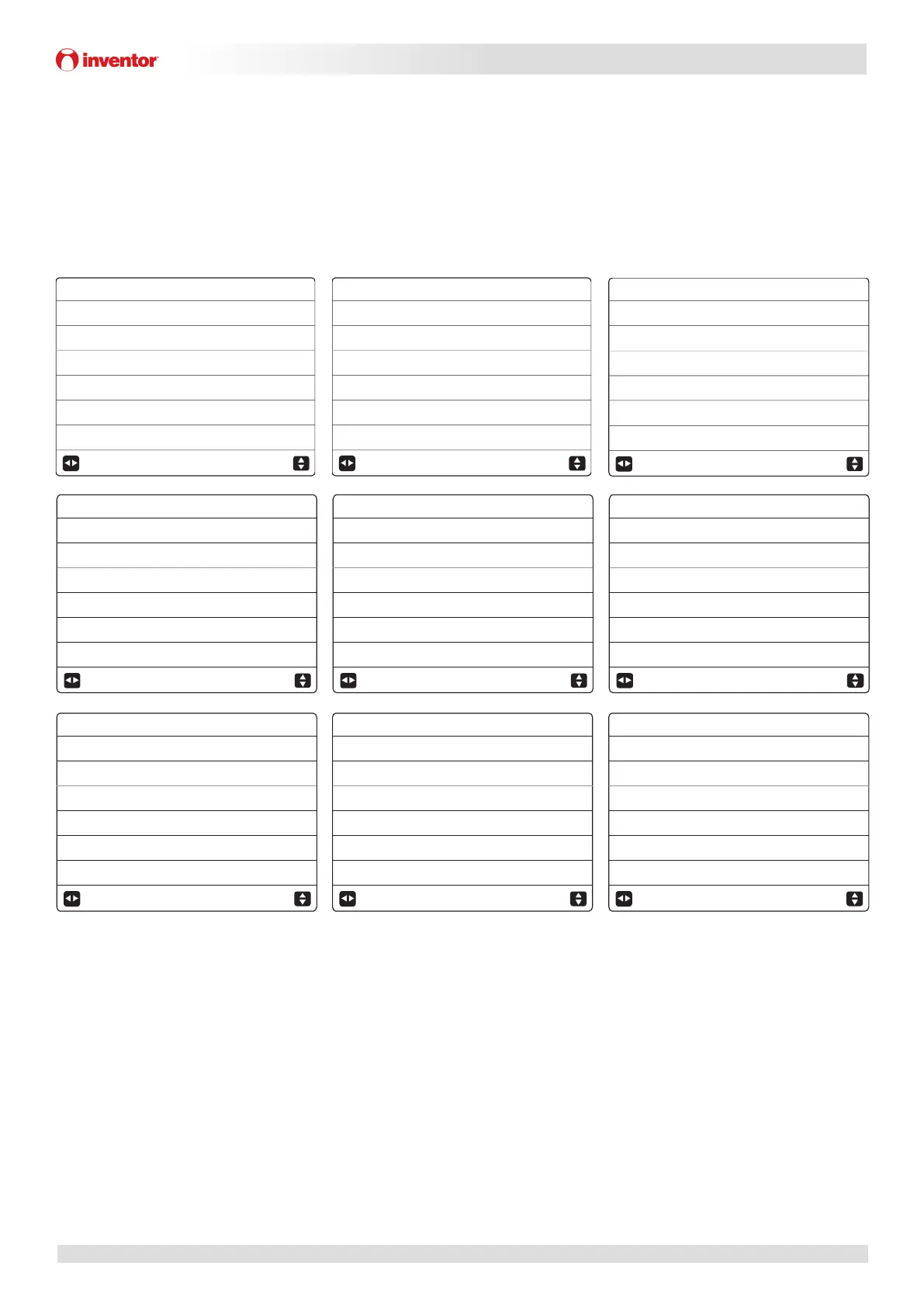

7.19 CASCADE SET

MENU > FOR SERVICEMAN > CASCADE SET

Figure 3-7.51:CASCADE SET

PER_START sets the start-up percentage of multiple units for the first time start-up after power on. For example:

Total units PER_START Starting units

6 50% 3

6 30% 2

TIME_ADJUST sets the judgment period of adding and subtracting units

ADDRESS RESET resets the address code of unit.( “FF” is an invalid address code.) Normally, program will set the address for each

unit automatically, only when unit lost address and Hd error code appears then we need to use this function. After setting the

address, you need to press the “UNLOCK” key to confirm.

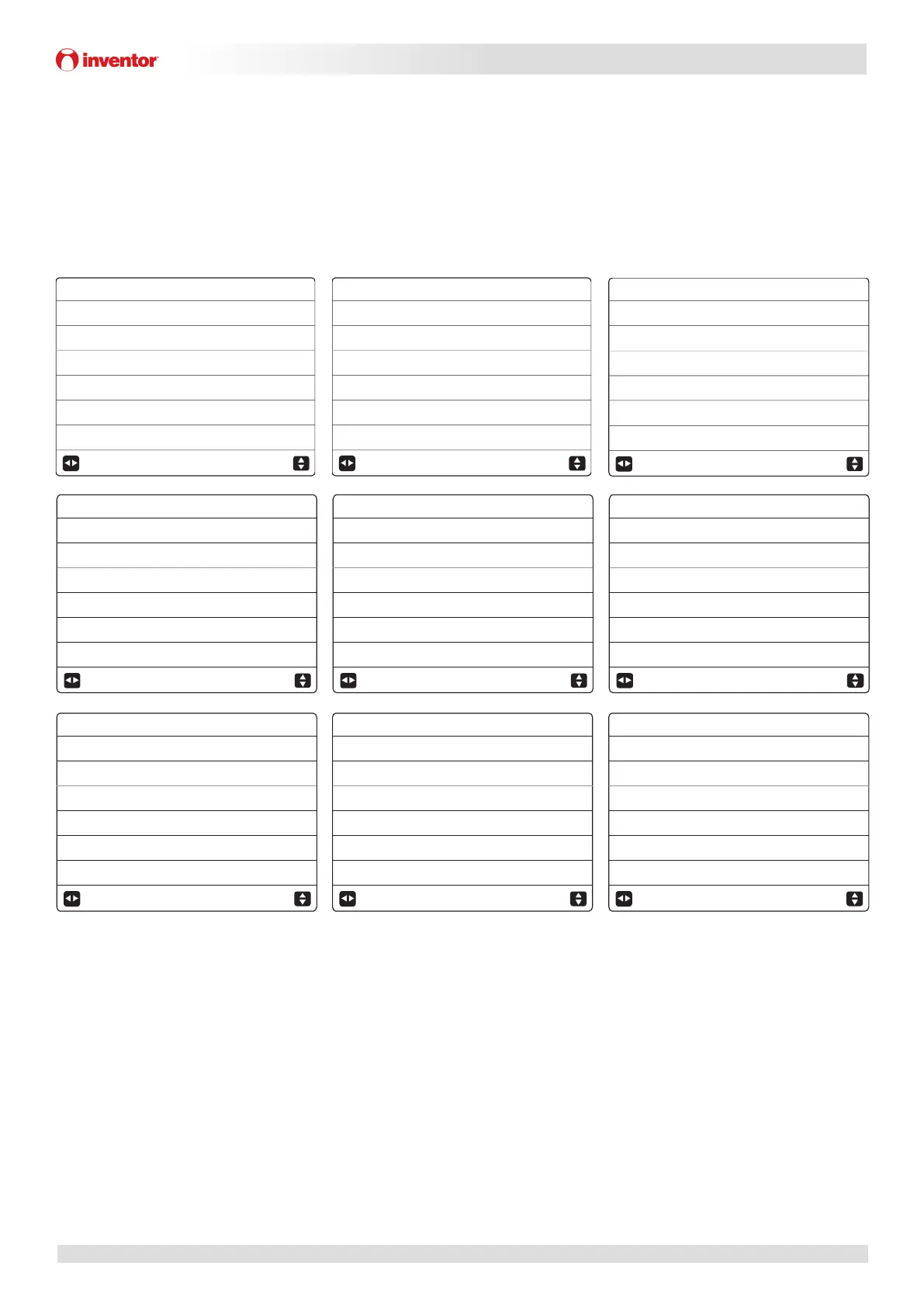

7.20 HMI ADDRESS SET

MENU > FOR SERVICEMAN > HMI ADDRESS SET

Figure 3-7.52: HMI ADDRESS SET

HMI SET sets the wired controller is master or slave. (0=MASTER, 1=SLAVE)

When HMI SET is set to SLAVE, the controller can only switch the operation mode, turn on or off, set the temperature, and

cannot set other parameters and functions.

HMI ADDRESS FOR BMS sets the HMI address code for BMS.(only valid for master controller)

16 CASCADE SET

20%

5 MIN

FF

ADJUST

16.1 PER_START

16.2 TIME_ADJUST

16.3 ADDRESS RESET

Go to MENU> FOR SERVICEMAN> 17.HMI ADDRESS SET

17 HMI ADDRESS SET

MASTER

0

ADJUST

HMI SET

HMI ADDRESS FOR BMS

Matrix Mono

95

Part 3 - Installation and Field Settings

8 Operation parameter

MENU > OPERATION PARAMETER

This menu is for installer or service engineer reviewing the operation parameters. There are nine pages for the operating

parameter as following

Figure 3-9.1: Operation parameter

OPERATION PARAMETER

#01

OPERATE MODE COOL

ADDRESS

SV1 STATE ON

ONLINE UNITS NUMBER 1

SV2 STATE OFF

SV3 STATE OFF

PUMP_I ON

1/9

OPERATION PARAMETER

#01

PUMP-C OFF

ADDRESS

PUMP-S OFF

PUMP-O OFF

PUMP-D OFF

PIPE BACKUP HEATER OFF

TANK BACKUP HEATER ON

2/9

OPERATION PARAMETER

#01

T1 LEAVING WATER TEMP. 35°C

ADDRESS

WATER FLOW 1.72m

3

/h

GAS BOILER OFF

HEAT PUMP CAPACTIY 11.52kW

POWER CONSUM. 1000kWh

Ta ROOM TEMP 25°C

3/9

OPERATION PARAMETER

#01

Tw2 CIRCUIT2 WATER TEMP. 35°C

ADDRESS

TIS’ C1 CLIMATE CURVE TEMP. 35°C

T5 WATER TANK TEMP. 53°C

TIS2’ C2 CLIMATE CURVE TEMP. 35°C

TW_O PLATE W-OUTLET TEMP. 35°C

TW_I PLATE W-OUTLET TEMP. 30°C

4/9

OPERATION PARAMETER

#01

Tbt2 BUFFERTANK_LOW TEMP. 35°C

ADDRESS

IDU SOFTWARE 01-09-2019V01

Tbt1 BUFFERTANK_UP TEMP. 35°C

5/9

Tsolar 25°C

OPERATION PARAMETER

#01

COMP.CURRENT 12A

ADDRESS

COMP.FREQENCY 24Hz

ODU MODEL 6kW

COMP.RUN TIME 54 MIN

COMP.TOTAL RUN TIME 1000Hrs

EXPANSION VALVE 200P

6/9

OPERATION PARAMETER

#01

IDU TARGET FREQUENCY 46Hz

ADDRESS

FREQUENCY LIMITED TYPE 5

FAN SPEED 600R/MIN

SUPPLY VOLTAGE 230V

DC GENERATRIX VOLTAGE 420V

DC GENERATRIX CURRENT 18A

7/9

OPERATION PARAMETER

#01

TW_I PLATE W-INLET TEMP. 30°C

ADDRESS

T2 PLATE F-OUT TEMP. 35°C

TW_O PLATE W-OUTLET TEMP. 35°C

T2B PLATE F-IN TEMP. 35°C

Th COMP. SUCTION TEMP. 5°C

Tp COMP. DISCHARGE TEMP. 75°C

8/9

OPERATION PARAMETER

#01

T4 OUTDOOR AIR TEMP. 5°C

ADDRESS

TF MODULE TEMP. 55°C

T3 OUTDOOR EXCHARGE TEMP. 5°C

P1 COMP. PRESSURE 2300kPa

ODU SOFTWARE 01-09-2018V01

HMI SOFTWARE 01-09-2018V01

9/9

Loading...

Loading...