ICP 3020 / ICP 4030 iMC-P Operating instruction

page 13

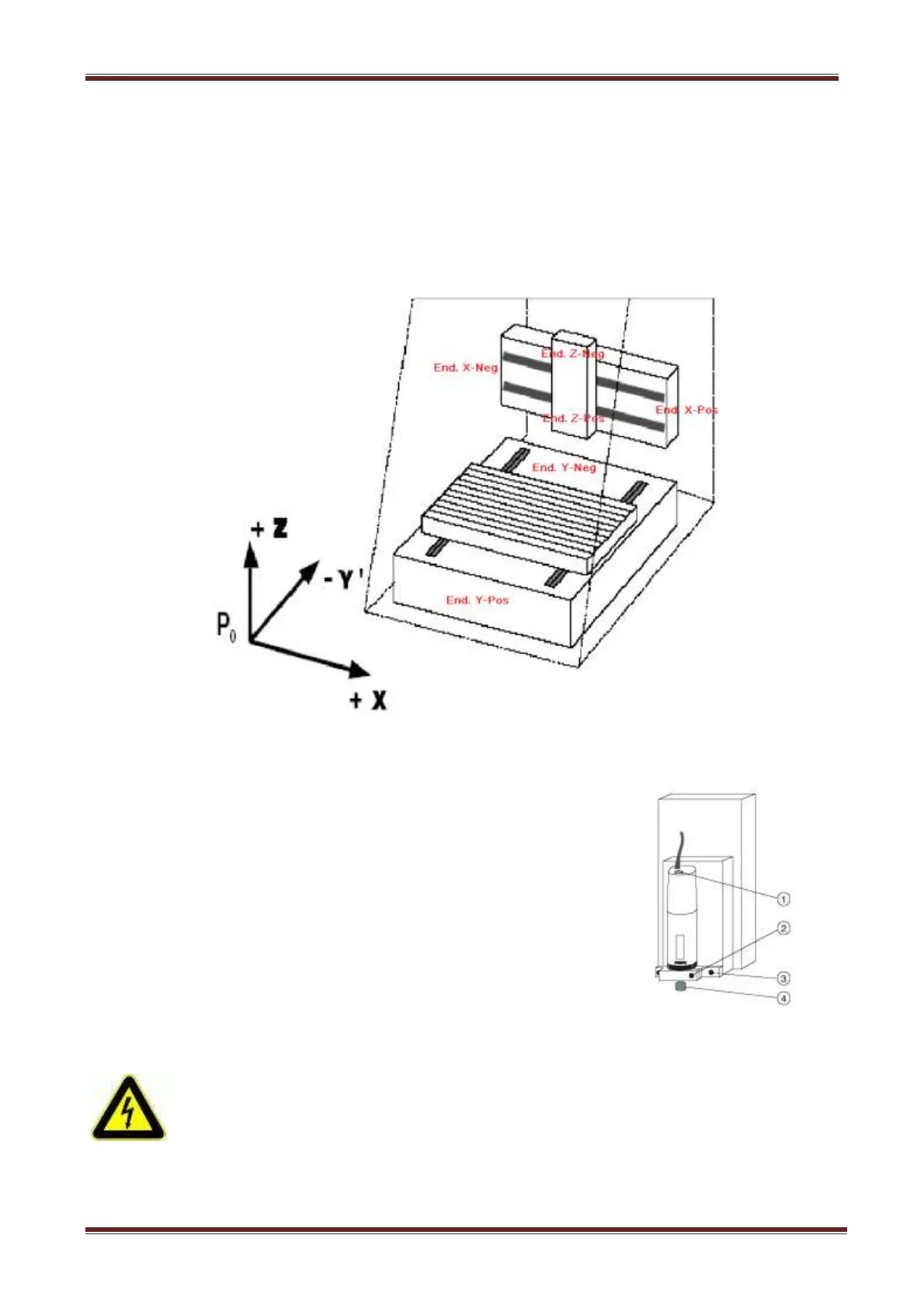

5.4 Coordinate system and reference point

The coordinate system of the machine is determined as shown in the figure. However, you

can select (displace) the P0 work piece zero point freely via software.

Ex works, the home position of the machine (machine origin) is defaulted to the back (Y), to

the left (X), and to the top (Z).

Labels on the machine mark the axes.

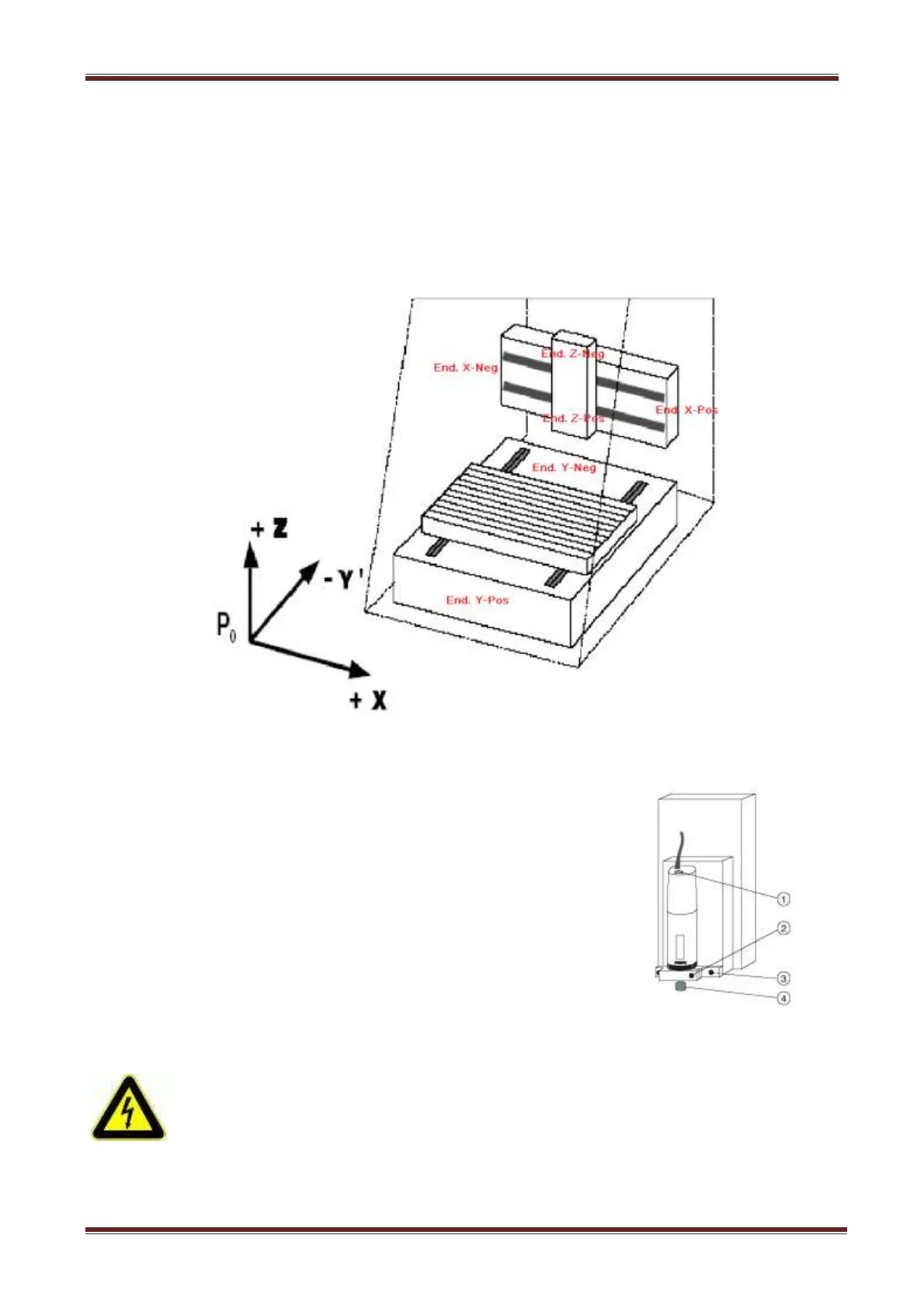

5.5 Tooling machine

In the collet (4) the standard tooling machine can take tools

with a maximum shaft diameter of 6.35 mm (standard 3 mm,

other diameters see Accessory). Use two SW 22 open end

wrenches for changing the collet.

The tooling machine is only enabled by the software. You can

manually adjust the rotation speed of the machine using the

(1)wheel.

Switch off the main switch of the ICP for dismantling the tooling

machine. Remove the electricity cable from the coupler terminal block,

loosen the clamping screw and take the tooling machine from the

holder.

For dismantling the machine with the holder, remove the electricity

cable, the two outside screws (3)

(loosen only, do not screw very out)

and remove the machine with holder and T-slot stones downwards.

Loading...

Loading...