32

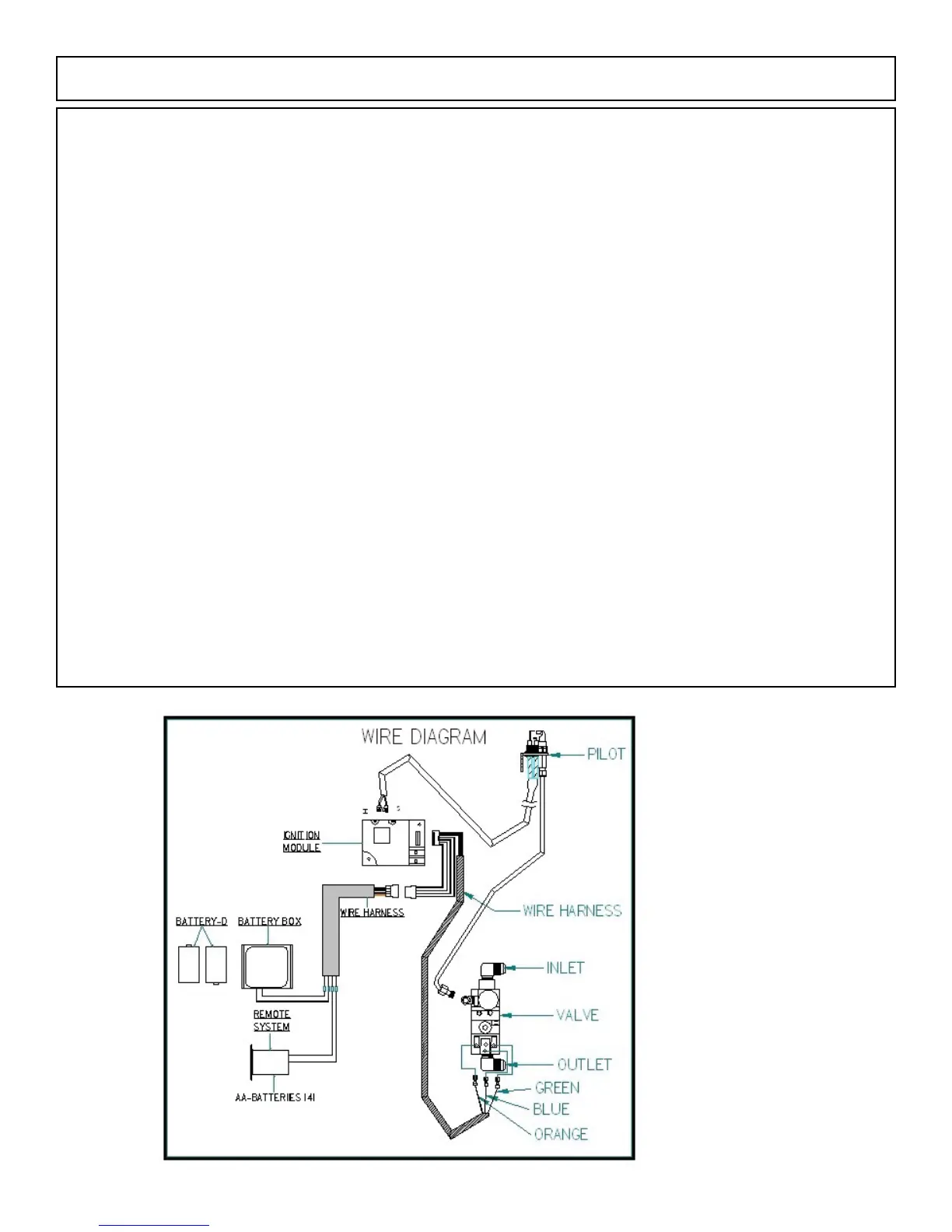

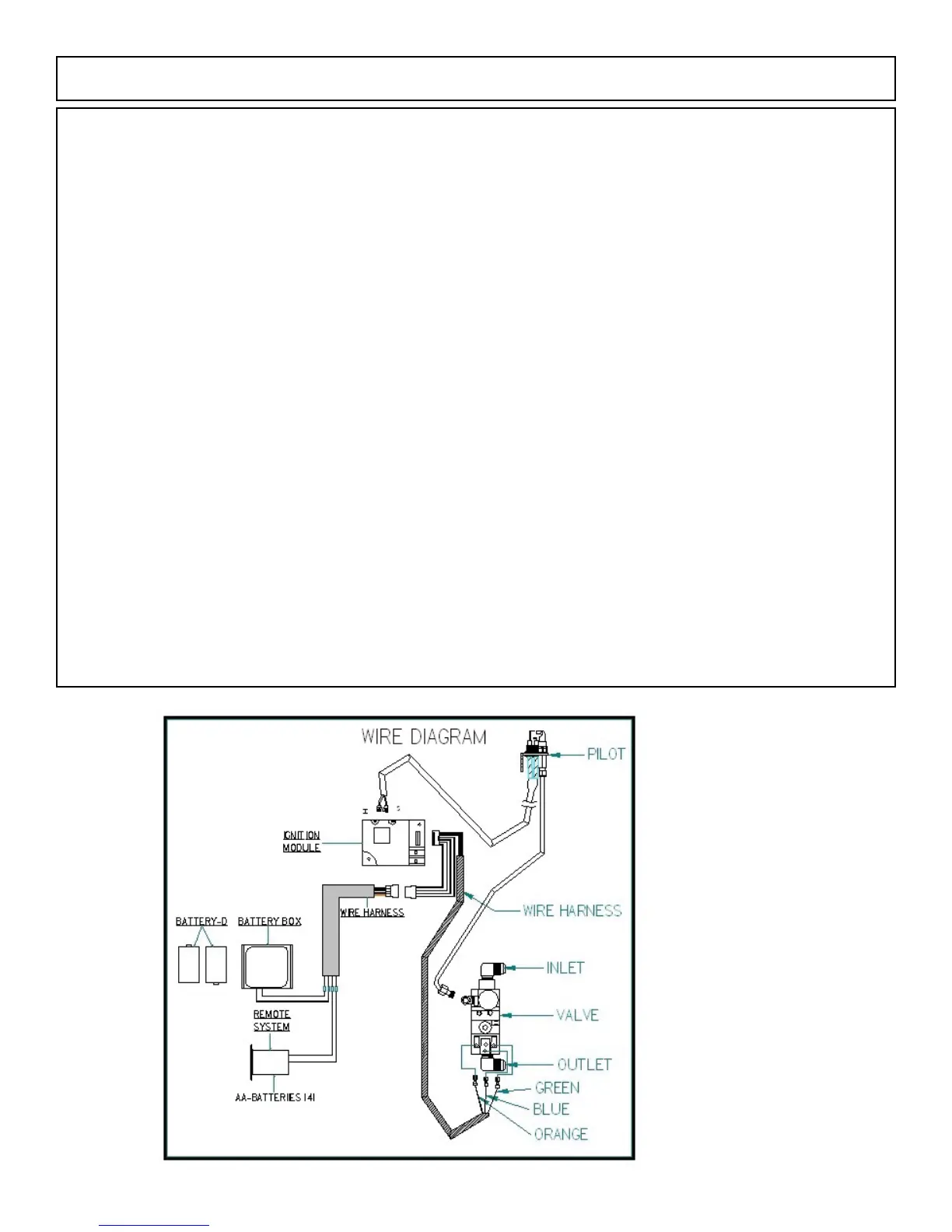

Safety Instructions Prior To Installation/Pilot Assembly Wire Diagram

ISOFLAMES FIREPLACE WIDTH FIREPLACE HEIGHT BTU NATURAL GAS BTU LIQUID

BURNER MINIMUM PROPANE

24” IBV 36” 30” 50,000 50,000

30” IBV 46” 30” 65,000 65,000

8. Gas supply pressures:

GAS SUPPLY PRESSURE NATURAL GAS LIQUID PROPANE

Minimum inlet gas supply pressure for the purpose of input adjustment 5” w.c. 10.5” w.c.

Maximum inlet gas supply pressure 7” w.c. 13” w.c.

Manifold pressure 3.5” w.c. 10” w.c.

The ISOFLAMES gas log system’s gas control valve must be disconnected from gas supply piping system during any pressure

testing of the ISOFLAMES gas log system at test pressures in excess of 1/2 psi (3.5kpa). The ISOFLAMES gas log system must

be isolated from the gas piping system by closing the gas control valve during any pressure testing of the gas supply piping system

at test pressures less than 1/2 psi (3.5kPa).

9. All ISOFLAME gas log assembly systems (whether with Safety Pilot Valve or Remote Pilot Valve) are equipped with a 1/8 NPT

plugged tapping, accessible for test gage connection, immediately upstream of the gas supply connection to the appliance.

10. The ISOFLAMES gas logs are convertible if done by a certied gas technician.

11. Keep the ISOFLAMES gas log system’s area clear and free from combustible materials such as gasoline and other ammable

vapors and liquids.

12. Do not use the ISOFLAMES gas log system if any part has been immersed in water. Call a qualied service technician to

inspect the ISOFLAMES gas log system. Replace any part of the ISOFLAMES gas log system that has been immersed in water.

13. The replace chimney and ue needs to be inspected and cleaned once a year by a qualied service technician.

Loading...

Loading...