6A–52 ENGINE MECHANICAL

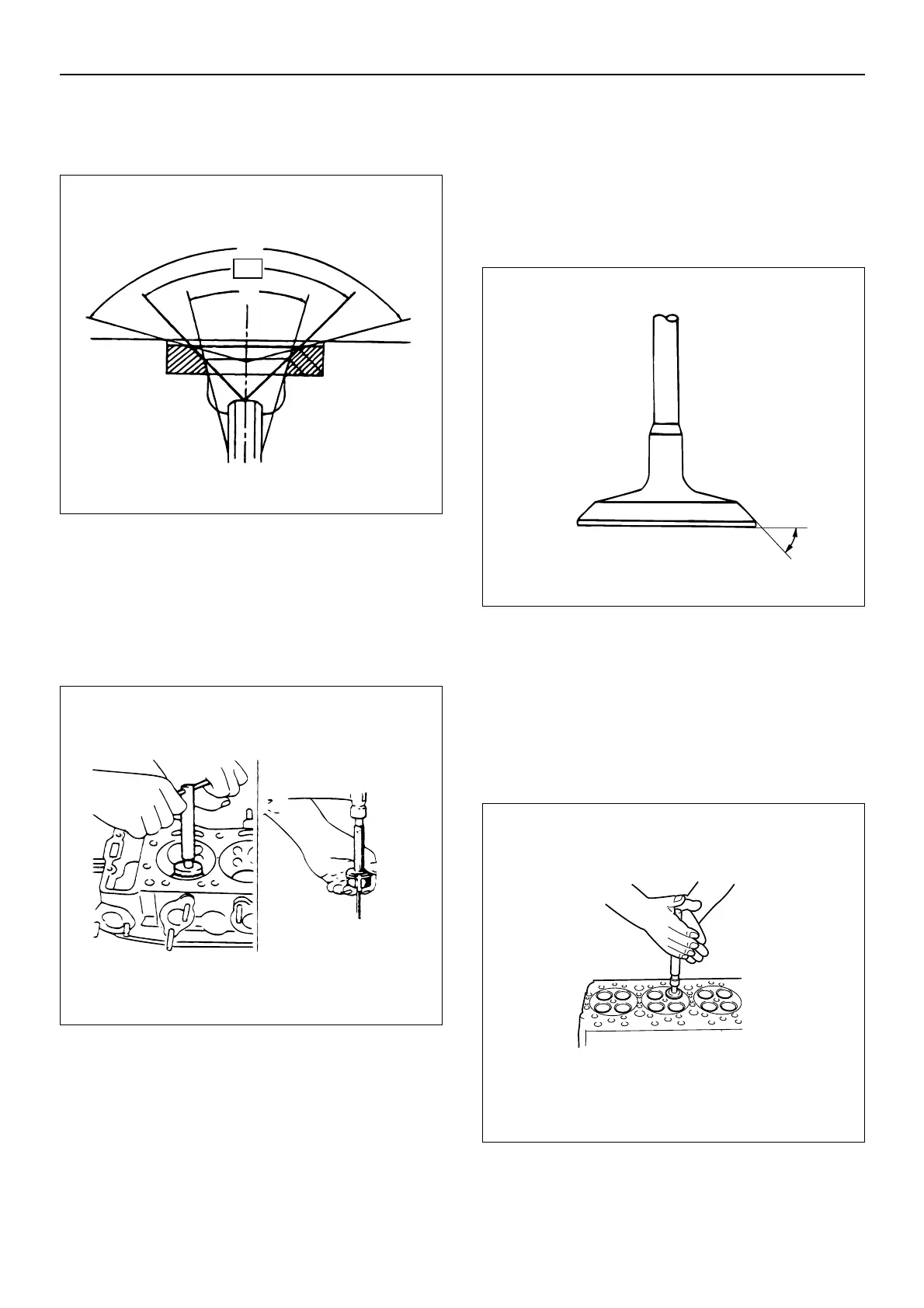

Valve Seat Insert Correction

1. Remove the carbon from the valve seat insert

surface.

2. Use a valve cutter (14, 45, 60 and 75 degree blades)

to minimize scratches and other rough areas. This

will bring the contact width back to the standard

value.

Remove only the scratches and rough areas. Do not

cut away too much. Take care not to cut away

unblemished areas of the valve seat surface.

Valve Face Angle

Intake: 30 degree

Exhaust: 45 degree

NOTE: Use an adjustable valve cutter pilot.

Do not allow the valve cutter pilot to wobble inside the

valve guide.

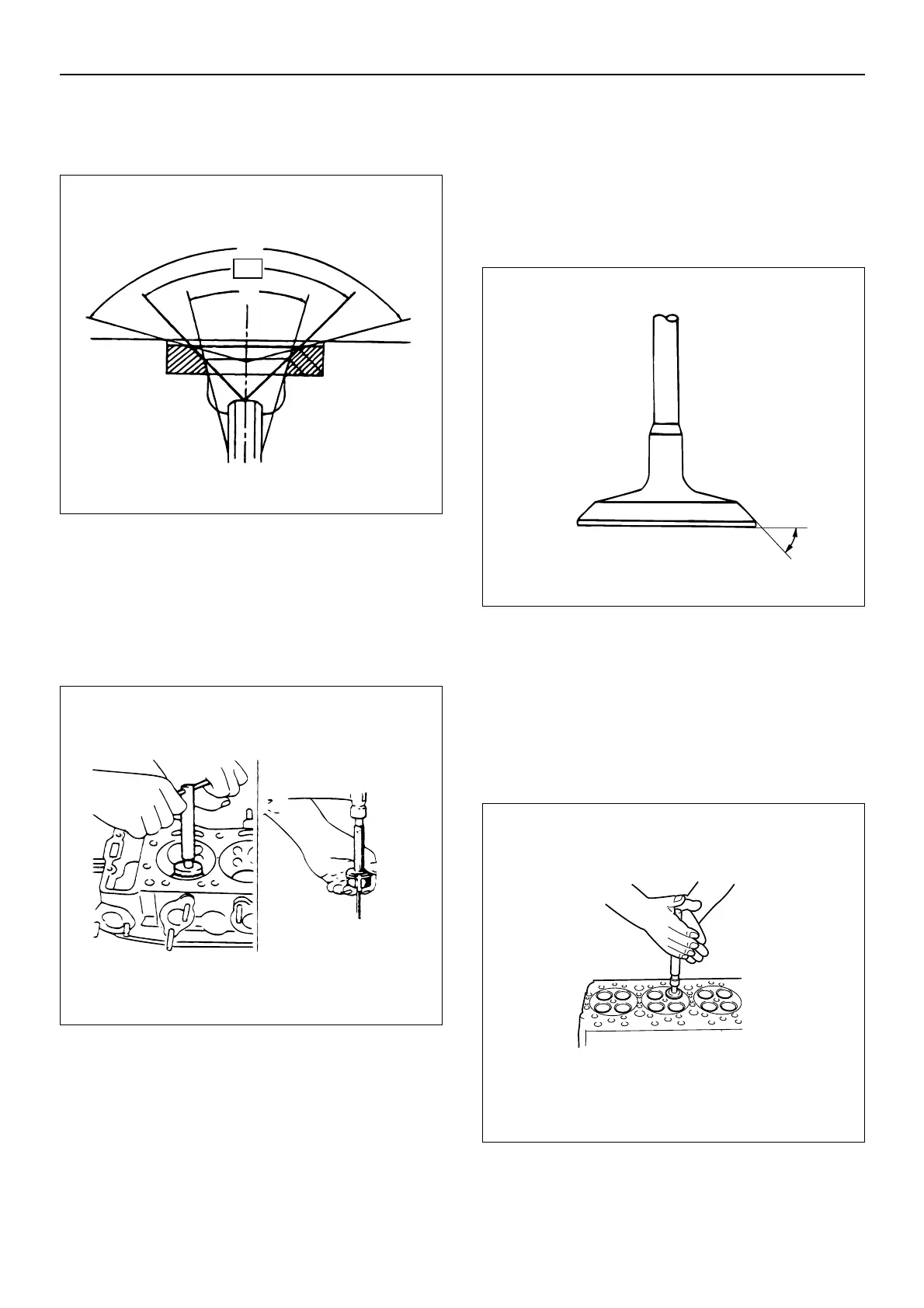

Check that valve depression is within the specified limit

after valve seat insert correction.

3. Apply abrasive compound to the valve seat insert

surface.

4. Insert the valve into the valve guide.

5. Turn the valve while tapping it to fit the valve seat

insert.

6. Check that the valve contact width is correct.

7. Check that the valve seat insert surface is in contact

with the entire circumference of the valve.

Loading...

Loading...