0B–6 SERVICE INFORMATION

Cooling System

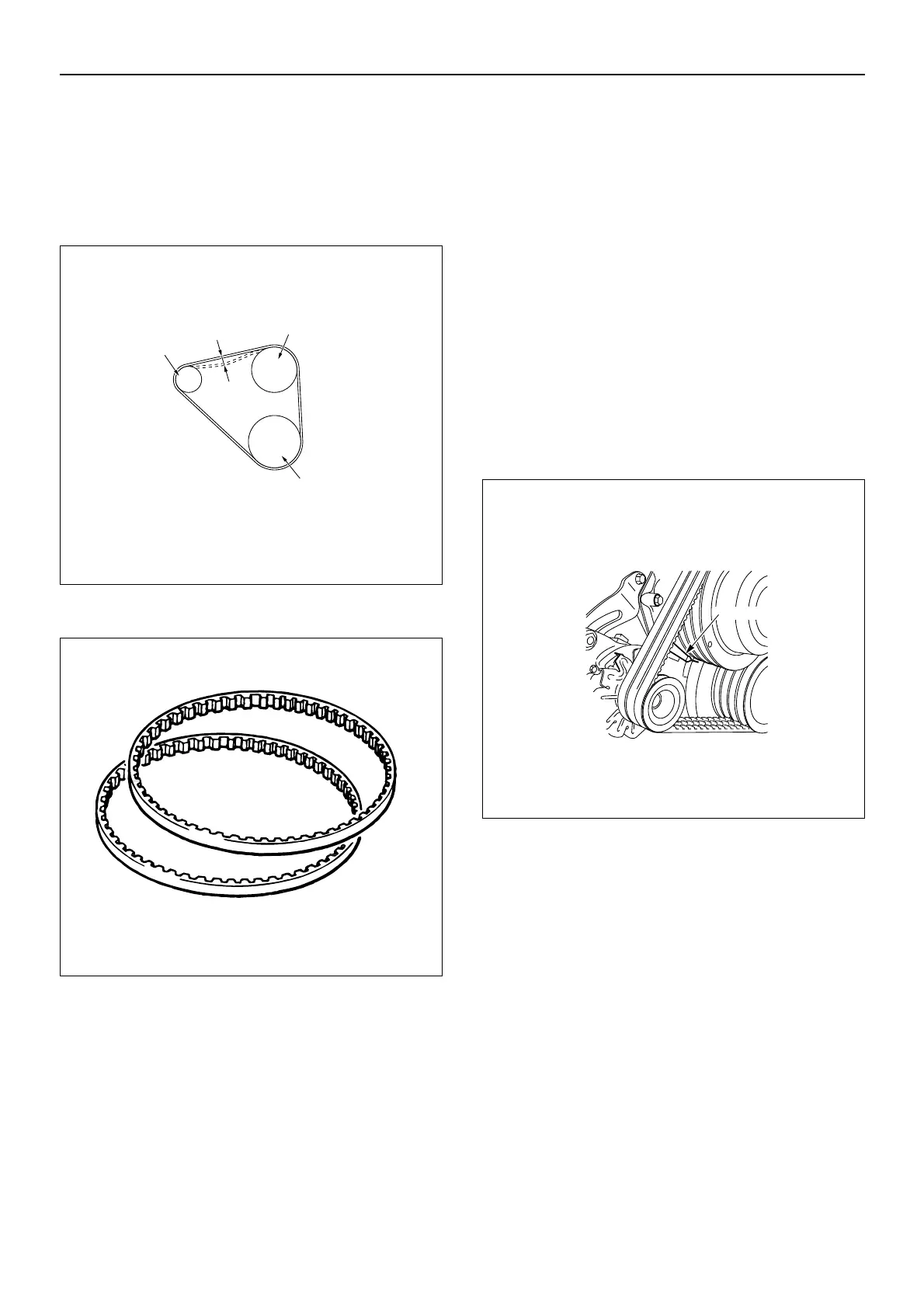

Fan Belt Inspection

Check the drive belt tension.

Depress the drive belt mid-portion with a 100 N (10kg/22

lb) force.

Drive Belt Deflection: 8 – 11 mm (0.31 – 0.43 in)

Check the drive belts for cracking and other damage.

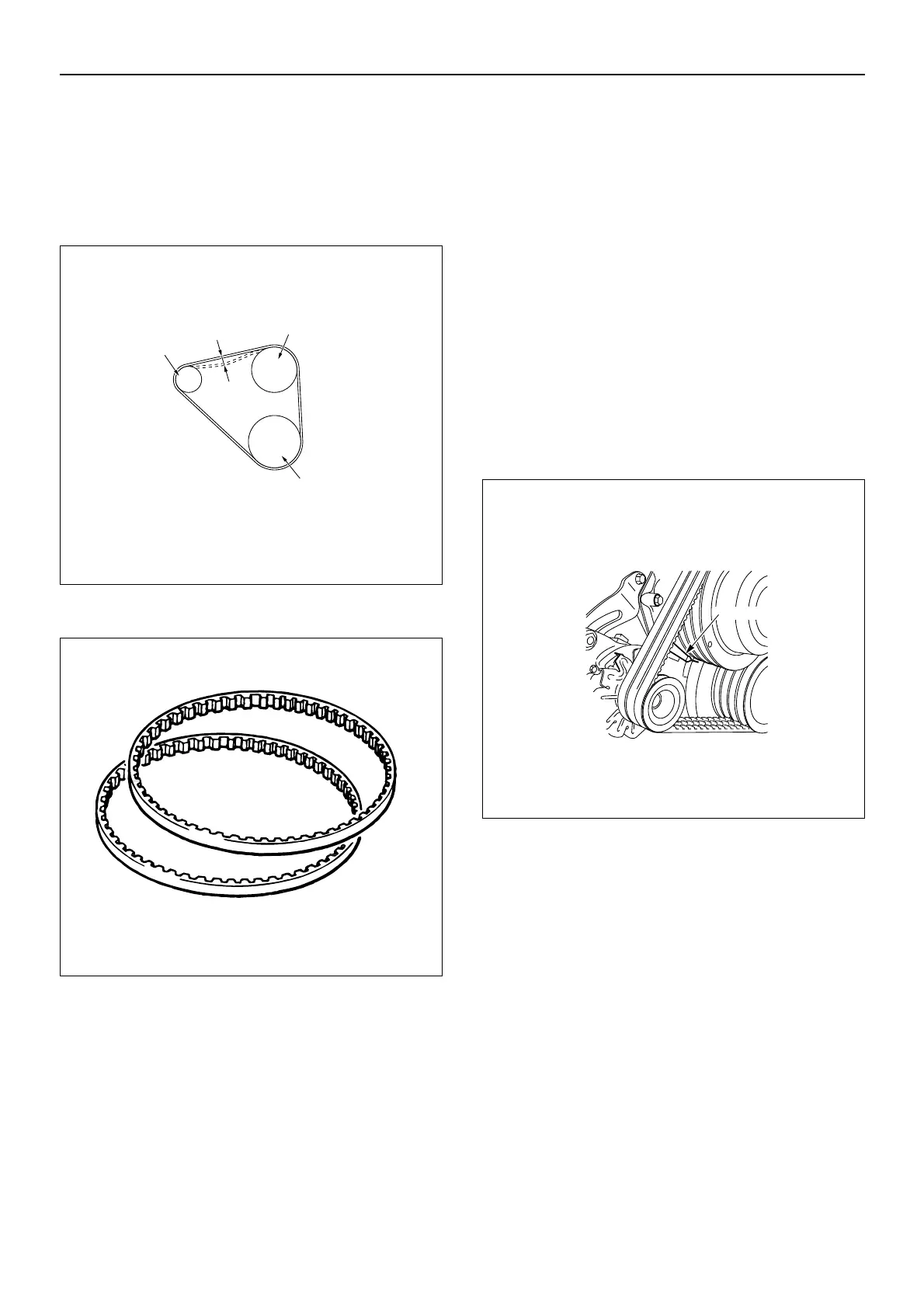

Valve Clearance Adjustment

The following instructions assume that valve clearance is

adjusted beginning with the No. 1 piston at top dead

center (TDC) on the compression stroke.

Check the alignment timing mark between the timing

advancer and the mark line on the injection pump body.

If the timing marks are aligned, the No. 1 piston is at TDC

on the compression stroke.

Valve clearance must be adjusted when the engine is

cold.

When removing the head cover, wipe off spilled oil with a

rag.

1. Bring the piston in the No. 1 or No. 6 cylinder to the

top dead center on the compression stroke by turning

the crankshaft until the T.D.C. line on the damper is

aligned with the timing pointer on the front cover.

Check the rocker arm shaft bracket nuts for looseness

and retighten as necessary before adjusting the valve

clearance.

2. Check that the No. 1 intake and exhaust rocker arms

have play. If they have play, it indicates that the No. 1

piston is at TDC (Top Dead Center) on the

compression stroke. If the No. 1 exhaust valves are

depressed, the No. 6 piston is at TDC on the

compression stroke.

3. Adjust valve clearances for the No. 1 or No. 6 cylinder

which its piston is at TDC on compression stroke.

1. Loosen each adjusting screw on the bridge and

rocker arm.

Loading...

Loading...