Plasma CUTTER 150

Operating Manual Page 11

9. Maintenance and safety check

This unit should be serviced in regular intervals dependent on Operating times and

working place conditions.

Before opening the machine switch off the plug!

- Check filter pressure reducer unit. Change cartridge, if required.

- Clean unit from inside by air-blasting according to degree of soiling.

Attention:

This Welding unit has to be safety checked every year by JÄCKLE Company or another

special qualified electrician according to the

harmonized standard

IEC 60974 – 4

Safety, maintenance and inspection of arc welding equipment in use

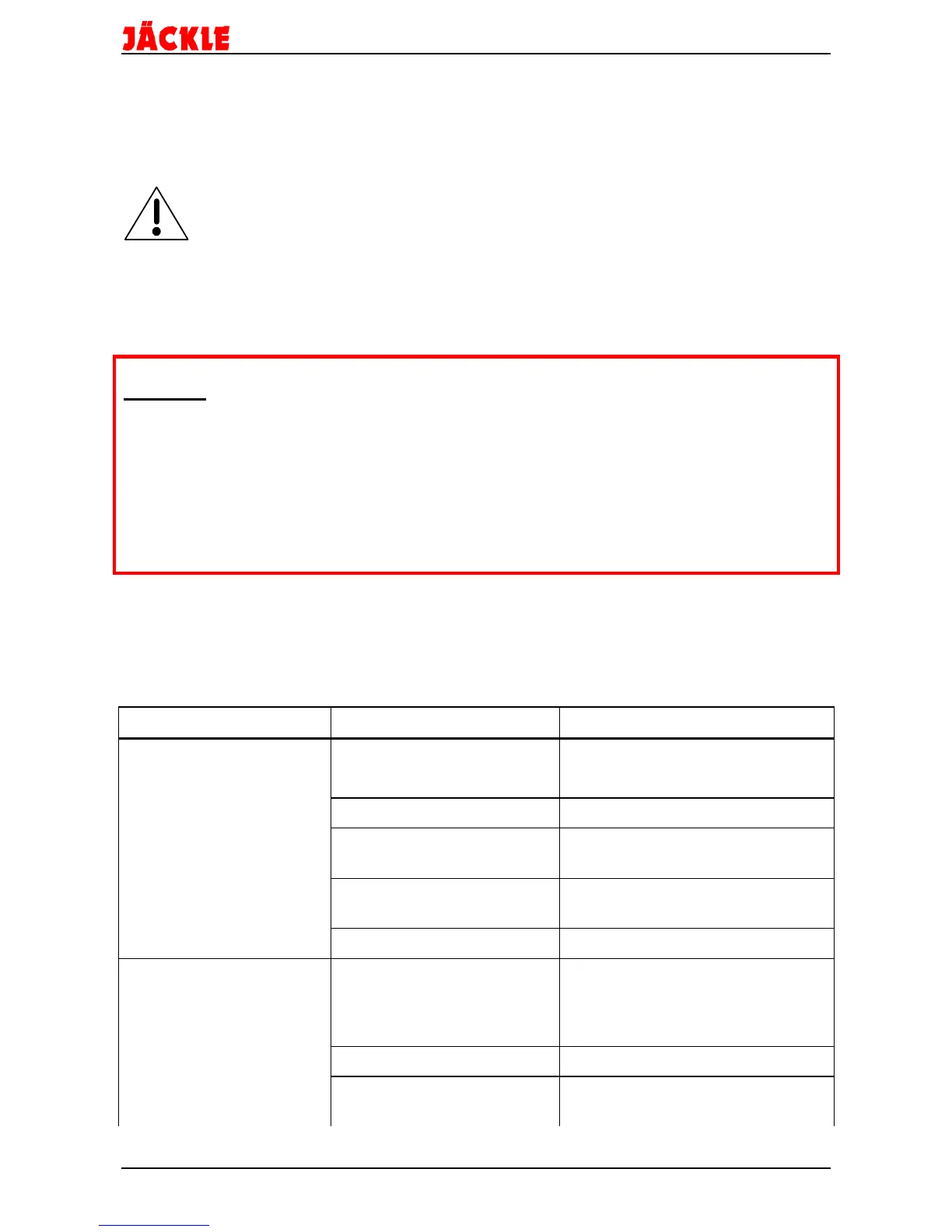

10. Trouble-Shooting

Malfunction/error Cause Remedy

mains connected and

master switch in pos.“I“ /

mains fuse has been

tripped

check mains fuse; if required,

increase fuse protection,

‘mains’ control lamp is mains cable interruption check mains cable

not lit fuse F1 (front side)

defective

change fuse F1

(T 2 A / 250 V)

defective fuse F2 on control

transformer

change fuse F2

(T 4 A / 250 V)

defective control lamp check / change control lamp

Torch trigger is pressed

down - no function

(no air, no tripping of

imperfect assembly of torch

head elements

(safety cutout)

check troch head

contactor) torch trigger defective check torch trigger

torch control line

interruption

check torch control line

Loading...

Loading...