ProTIG 220/300 AC/DC

Operating manual Page 31

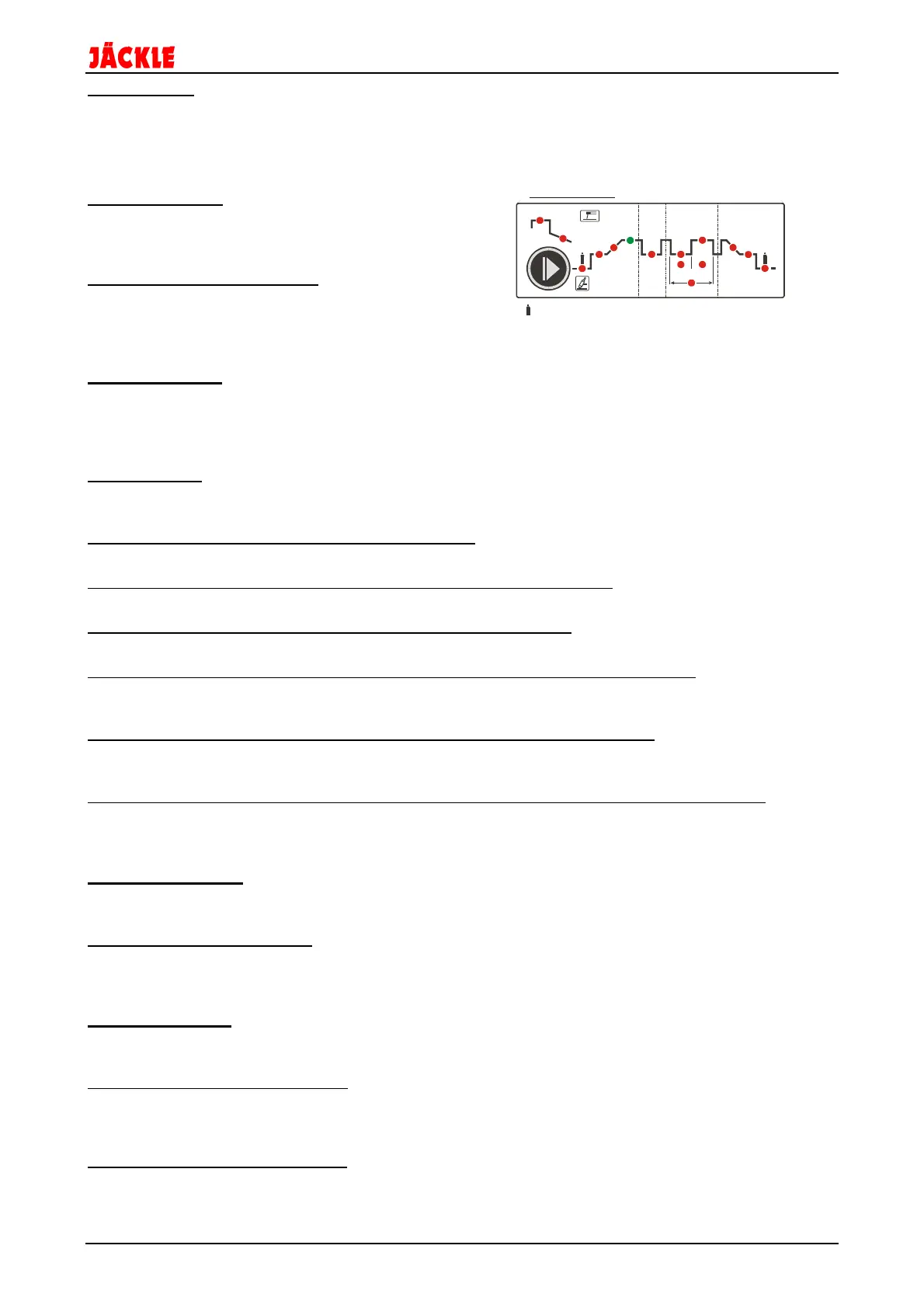

lb

lp

1

I

2

HOTSTART

ARCFORCE

SU SD

IS IE

PULS

I

- Gas pre flow time / Gas post flow time

IS - Start current

SU - Slope Up time

I - Main current

I - Cycle current (only in I mode)

lb - Base current (only in Pulse mode)

lp - Pulse current ( )

Tb - Base current time

Tp - Pulse current time

f - Pulse frequency

SD - Slope down time

IE - Final welding current

1

2 2

only in Pulse mode

(only in Pulse MAN mode)

(only in Pulse MAN mode)

(only in Pulse AUTO/SPEED mode)

4. Functions:

Below all functions and parameters of the machine are explained. Which function is available for which mode

is in brackets. To call a function / parameter, the function key (item 4) must be pressed again until the

corresponding LED flashes. Then the value can be changed by using the rotary knob (item 9).

Finish the settings by long pressing the function key (item 4).

Gas pre flow time:

This time can be adjusted between 0.05 and 1 second,

which opens the gas valve before the start of the welding

operation. The torch can be flooded with gas.

Start current IS (4-cycle mode):

With the start current every welding process is started. It

can be set between 5 and 220/300A. The default value is

set to 40A. (In 2-cycle mode this value can only be changed

in expert mode. This is described in Chapter 24th.)

Slope-up time SD:

The Slope-up time is the time, in which the machine rise

from

start current IS to the main current I1. This time can be set

from 0 to 5 seconds in 0.1 second increments.

Main current I

1

:

The main welding current I

1

can be adjusted in each

operating mode from 5 to 220/300A.

Current I

2

(possible only with actived I2 mode (LED 32):

The secondary welding current I

2

can be adjusted from 5 to 220/300A.

Pulse Base current Ib (

possible only with activated pulse function

(Pos. 8)):

Hereby the pulse base current (lower welding current) can be adjusted from 5 to 220/300A.

Pulse current Ip (

possible only with activated pulse function

(Pos. 8)):

Hereby the pulse current (welding current) can be adjusted from 5 to 220/300A.

Pulse Base current time Tb (

possible only with activated MAN pulse function

(LED 82):

Hereby the time from 0.01 to 0.99 seconds can be set, with which the machine holds the base current Ib in

the pulsed mode. (0,01s = 100Hz and 0,99s = 1 Hz)

Pulse current time Tp (

possible only with activated MAN pulse function

(LED 82):

Hereby the time from 0.01 to 0.99 seconds can be set, with which the machine holds the pulse current Ip in

the pulsed mode. (0,01s = 100Hz and 0,99s = 1 Hz)

Pulse frequency (

possible only with activated

AUTO (LED 80) or SPEED (LED 81)

pulse function

:

When AUTO pulse function is activated, the pulse frequency can be adjusted between 30 and 500Hz.

When SPEED pulse function is activated, the pulse frequency can be adjusted between 0,5Hz and 2000Hz

(2kHz).

Slope-down time SD:

The Slope-down time is the time, in which the machine decreases from main current I1 to the End current IE.

This time can be set from 0 to 8 seconds in 0.1 second increments.

End current IE (4-cycle mode):

With the End current IE, every welding process is terminated. It can be set between 5 and 220/300A.

The default value is set to 20A. (In 2-cycle mode this value can only be changed in expert mode.

This is described in Chapter 24th.)

Gas post flow time:

This time can be adjusted between 0.5 and 25 seconds, which opens the gas valve at the end of the welding

operation. The torch can be cooled with gas.

Hotstart: (only for electrode welding):

With the parameter ‘Hot start’ it is possible to set the current, with which the electrodes ignites.

This value can be adjusted from 0% (no increased ignition) to 100% (double ignition current) of the actual

welding current I1.

Arcforce (only for electrode welding):

With the ‚Arc Force‘ parameter a sticking of the electrode during welding can be prevented.

For this purpose, the welding current is temporarily increased.

This value can be adjusted from 0% (no increased current) to 100% (double current) of the actual welding

current I1.

Loading...

Loading...