07610-002-41-09-F

8

INSTRUCTIONS

INSTALLATION

INSTALLING THE

HOOD ASSEMBLY

ALIGNING THE

MACHINE

INSTALLING THE

INTERNAL VACUUM

BREAKER

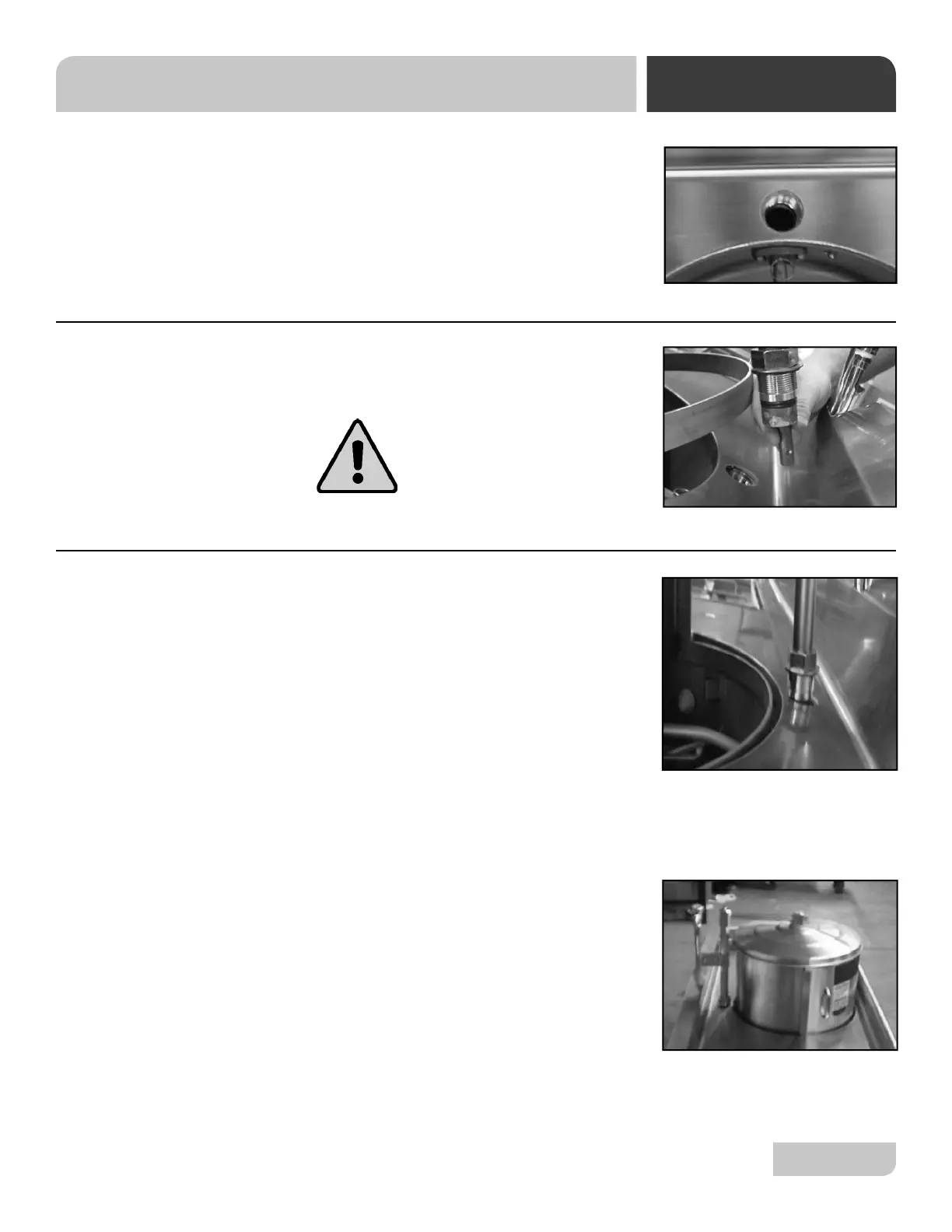

Adjust the machine base to align hole in table

with hole in support block (Fig. 10).

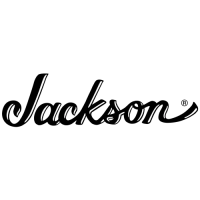

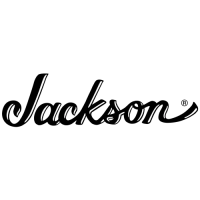

Insert internal vacuum breaker pipe into hood

support block pin end down (Fig.11).

WARNING: Internal vacuum

breaker pipe must be installed

or there will be a hazard to the

operator.

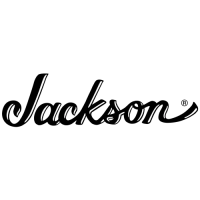

Make sure there are two “O-rings” (Fig. 3) on the

lower support pipe near the end of the ring. While

also holding the internal vacuum breaker, lift the

hood and hood support pipe up over table. Set

hood support pipe down into the support block

hole (Fig. 12) and begin to work the hex nut into

the hole. The locating pin in the support block

will ensure proper alignment. While holding

the support pipe, start tightening nut by hand

to prevent cross-threading (it should tighten

considerably by hand), then continue tightening with a wrench. It may be necessary to

work support pipe back and forth to seat nut properly. When the nut is tight, it should

force fl at the stainless steel and rubber washers tight to the table top.

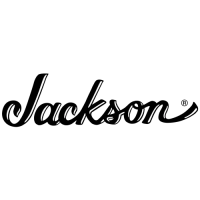

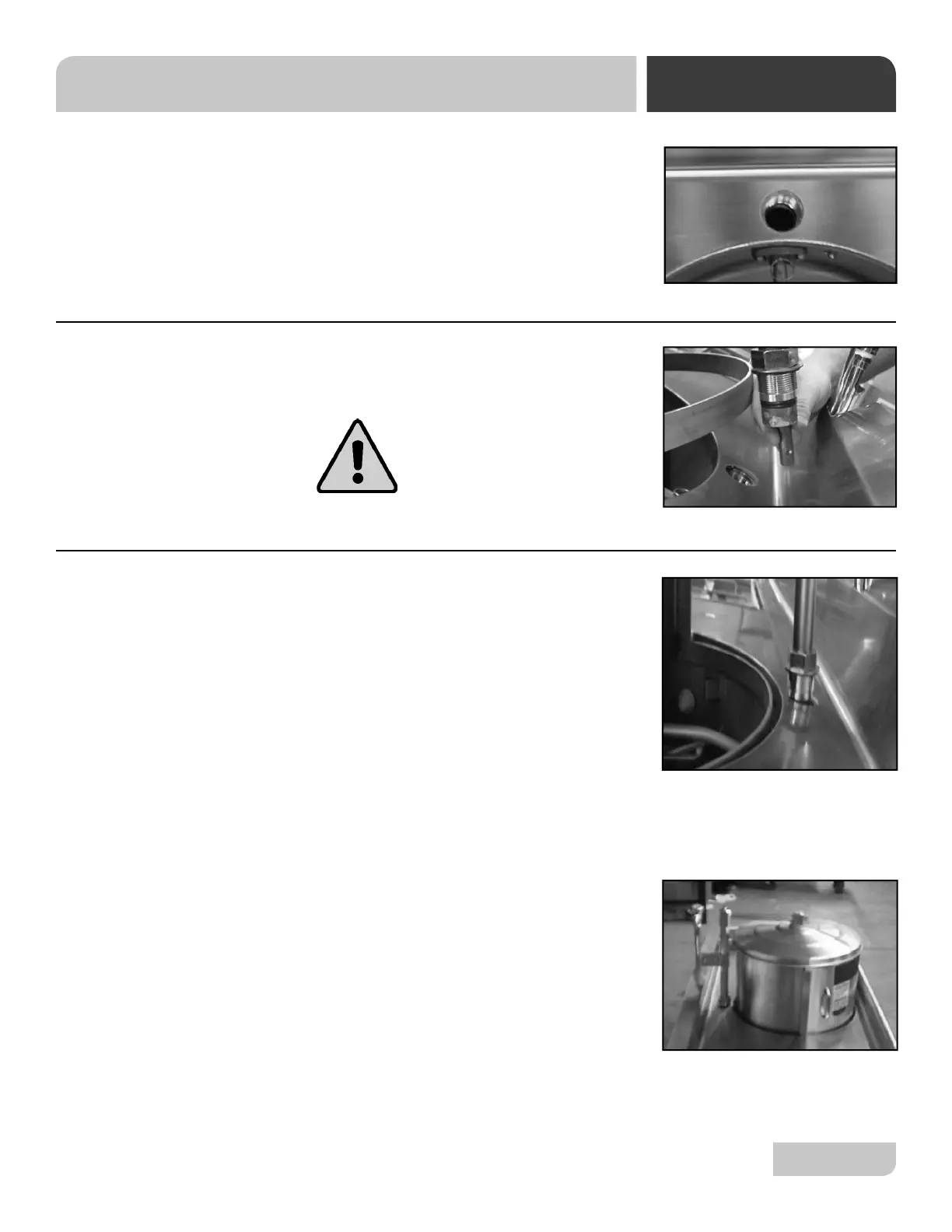

Attach vacuum breaker support pipe clamp (Fig.

13) to the support pipe and external vacuum

breaker piping. Slide up about 12” from the

table and tighten securely. Position cover plate

(supplied with table) over square cutout in

backsplash on table so that it fi ts tightly around

piping then snap in the four nylon fasteners

(supplied) to hold in place.

Rotate the hood to ensure it is free. If not, check level of machine, tightness of table

to machine fl ange, centering of machine, level of table, and hood support pipe.

(Fig. 10)

(Fig. 11)

(Fig. 12)

(Fig. 13)

Loading...

Loading...