Page 24 ENGLISH

Jandy

®

TruDose

TM

Chemical Controller

|

Installation & Operation Manual

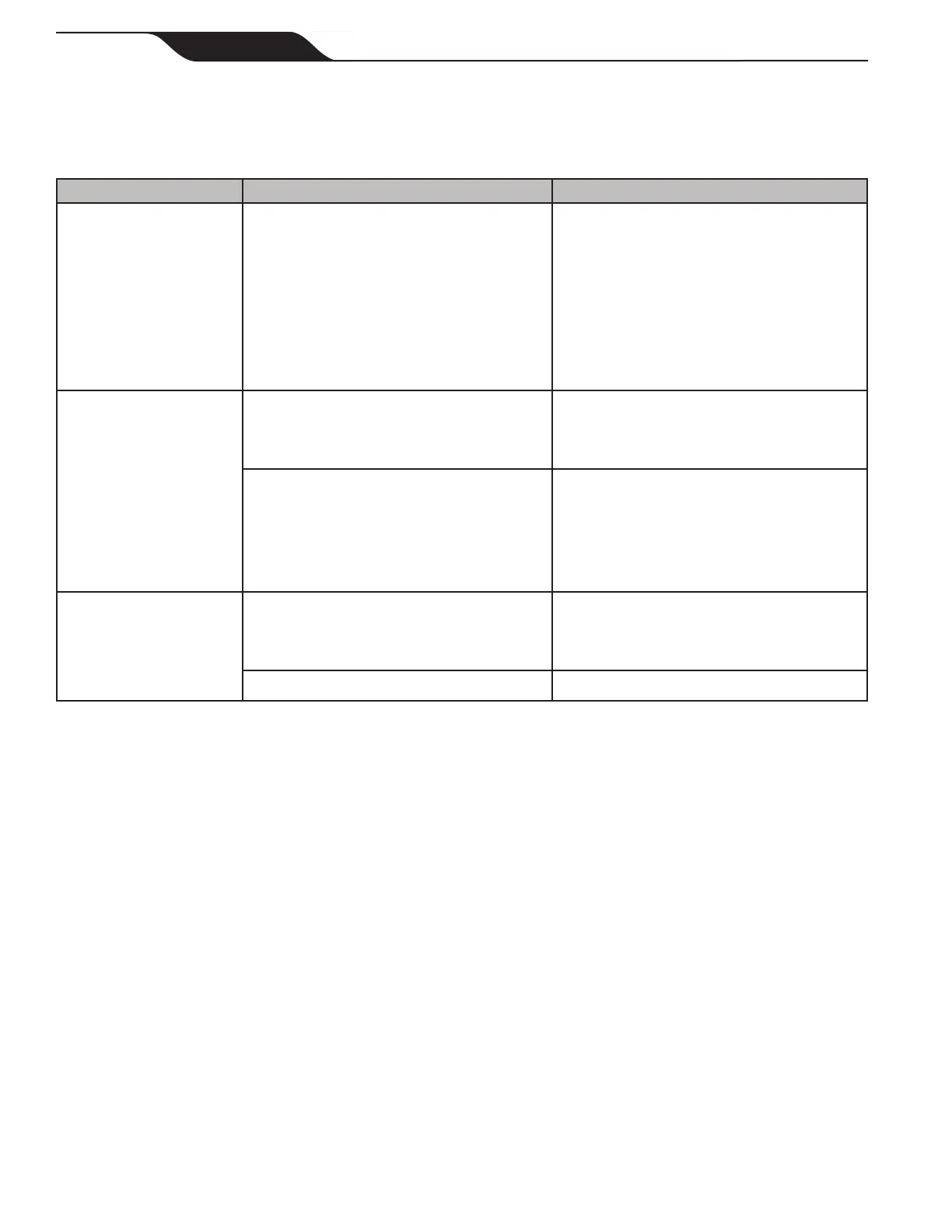

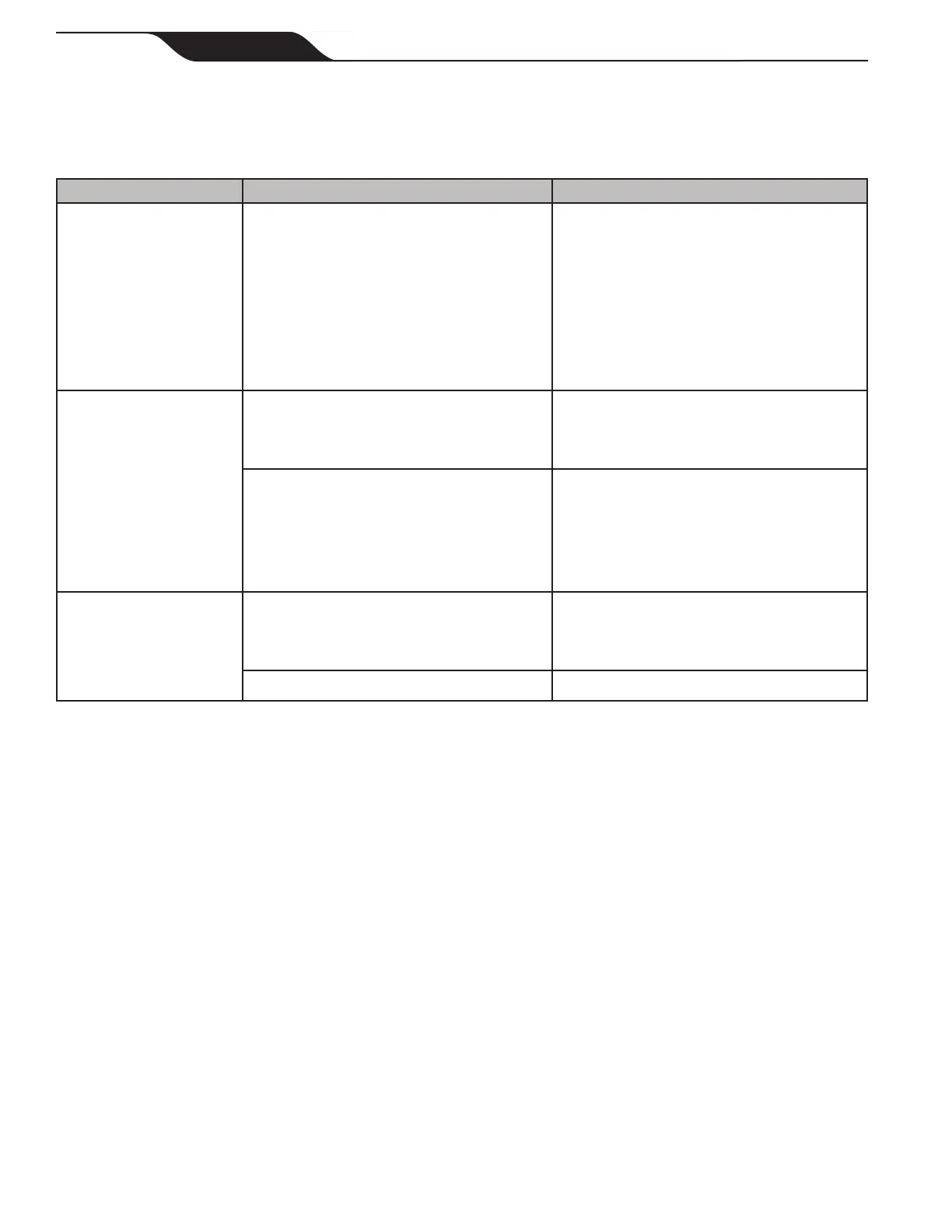

Section 8. Chemical Pump Tube Troubleshooting

NOTE: A leaking pump tube damages the metering pump. Inspect the pump frequently for leakage and wear.

Refer to the Tube Replacement section for additional safety precautions and instructions.

Problem Possible Cause Corrective Action

Tube leaking Pump tube ruptured. Replace pump tube and ferrules.

Calcium or mineral deposits. Cleaninjectiontting,replacepumptube

and ferrules.

Excessive back pressure. Ensure system pressure does not exceed

25 psi (1.7 bar) maximum.

Tube is twisted. Replace pump tube and ferrules.

Tube not centered. Replace pump tube and ferrules.

Tube life is shortened. Incompatibilitywithuid. Check compatibility.

Mineral deposits at injection point. Remove deposits, replace pump tube and

ferrules.

Sedimentblockageatinjectiontting.

Seized rollers caused abrasion on tube.

Exposure to heat or sun.

Maintain suction line 2-3" above bottom of

tank.

Clean roller assembly or replace.

Do not store tubes in high temperatures or

in direct sunlight.

Tube connection is

leaking.

Missing ferrule on suction or discharge

line.

Replace ferrule.

Crushed ferrule. Replace ferrule.

Ferrule in wrong orientation. Reverse orientation of ferrule.

Loading...

Loading...