page 22 / 27

7. Maintenance

Follow all the instructions given in this manual, in particular the instructions in the Safety Section.

This machine must be maintained by qualied personnel in compliance with the warnings on the machine and in

compliance with the user manual.

Keep hands, hair, loose clothing and/or jewelry, etc., clear of moving parts of the machine. Wear suitable

garments without loose parts. Wear suitable work shoes.

Do not remove any connections or guards while the machine is turned on. The machine may be used only when

all protective devices and safeguards are correctly tted and ready for use.

Always pull the plug from the socket before carrying out maintenance work. Some items of personal protective

equipment must be worn when carrying out maintenance work (see subsection 2.3).

Warn the operating personnel that maintenance work is going to be carried out before beginning the work.

Interrupt the power supply, when possible, before inspecting or carrying out maintenance on the machine: turn

the power switch to off, lock the power switch so that it cannot be turned to on and unplug the power cable from

the plug box. When the power supply needs to remain connected to carry out specic work on the machine then

call in an extra person who can operate the emergency stop switch.

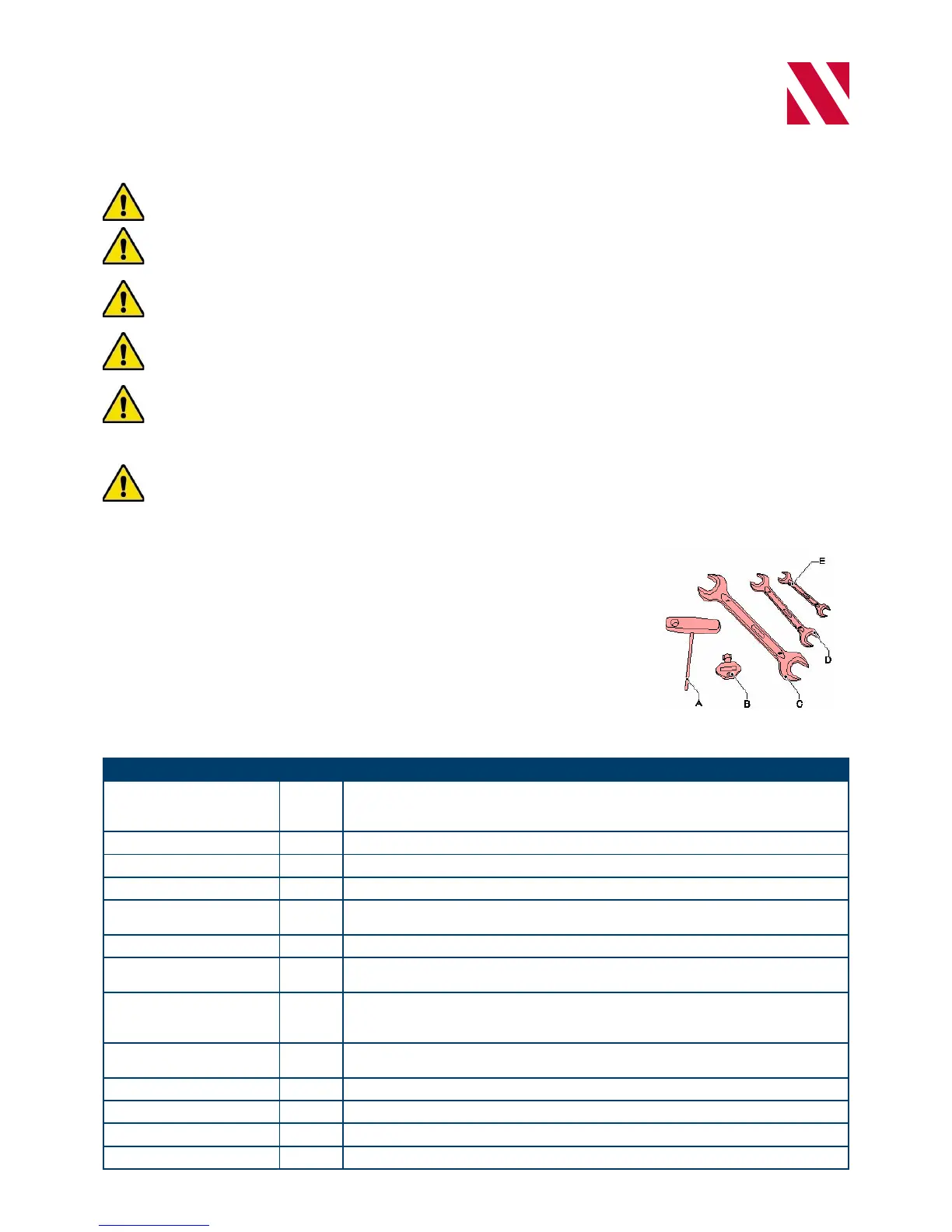

7.1. Maintenancetoolsandequipment

Asetoftoolssuppliedwiththemachinecomprises:

A. Hex key 4 mm

B. Hatch key

C. Openendwrench,24-27mm

D. Openendwrench,17-19mm

E. Openendwrench,10-13mm

7.2. Preventivemaintenance

The following maintenance instructions are based on normal use. The maintenance frequency should be increased

for intensive use or use in extreme conditions.

Item 1xper... Notes

Machine Day

Blow clean with compressed air at the end of each day to avoid problems

withthepottrackjamming,etc.Soilresiduesoftenremainon/inthepot

track,drill,drilldriveandelevator.

Soil bin Day Empty.Seethe“Emptyingsoilbin”subsection.

Elevator and belts Day Checktension.Seethe“Assembly,installationandcommissioning”Section.

Elevator buckets Day Clean.Seethe“Cleaningelevatorbuckets”subsection.

Materials in the machine Day

Remove any pots or other materials than have fallen into the machine before

it is turned on again.

Drill unit 40 hours Lubricatedrillunit,see“Lubricatingdrillunit”subsection.

Greasettings

6

months

Greasethegreasettingsontheelevatorangebearing(2x)andpottrack

drive shaft (3x).

Gearbox

6

months

Check oil level (3/4 full is OK). Add HTx 320 oil if necessary. When you doubt

whethertheoilinthegearboxisHTx320,thendrainthegearboxandllwith

HTx 320 oil.

Oil seal

6

months

Check for leaks.

Safety components Week Testthesafetycircuit.Seethe“Testingsafetycircuit”subsection.

Icons Week Check legibility and replace if necessary.

Electrical system Year Check for damage.

Electric motors Year Remove dust.

Loading...

Loading...