Reconditioning (cont’d)

Bushing Assembly

Note: Jig details are in accordance with ram sizes. See Service Tools, Section 1.

77 - 7

Section E Hydraulics

9803/6410

Section E

77 - 7

Issue 1

Hydraulic Rams

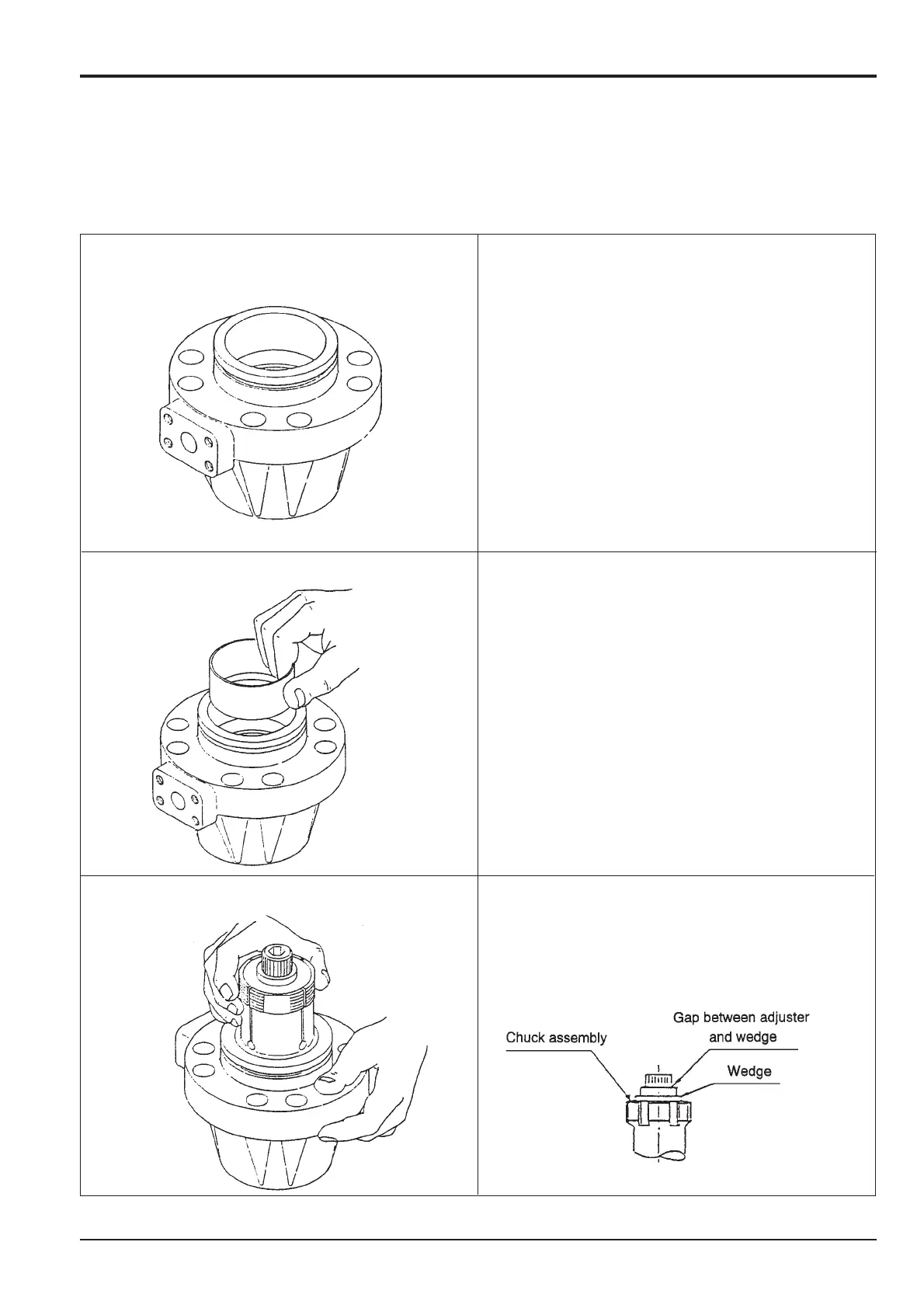

Set the cylinder head on the press bench with the tube

connecting surface facing up.

1 Keep the work bench clean so that dust or other

foreign matter does not damage the bottom surface

of the cylinder head. Also make sure that it is level.

2 Use compressed air to remove the foreign matter.

! CAUTION

When using compressed air, wear safety glasses and

gloves. Do not direct compressed air at your skin.

8-3-4-2

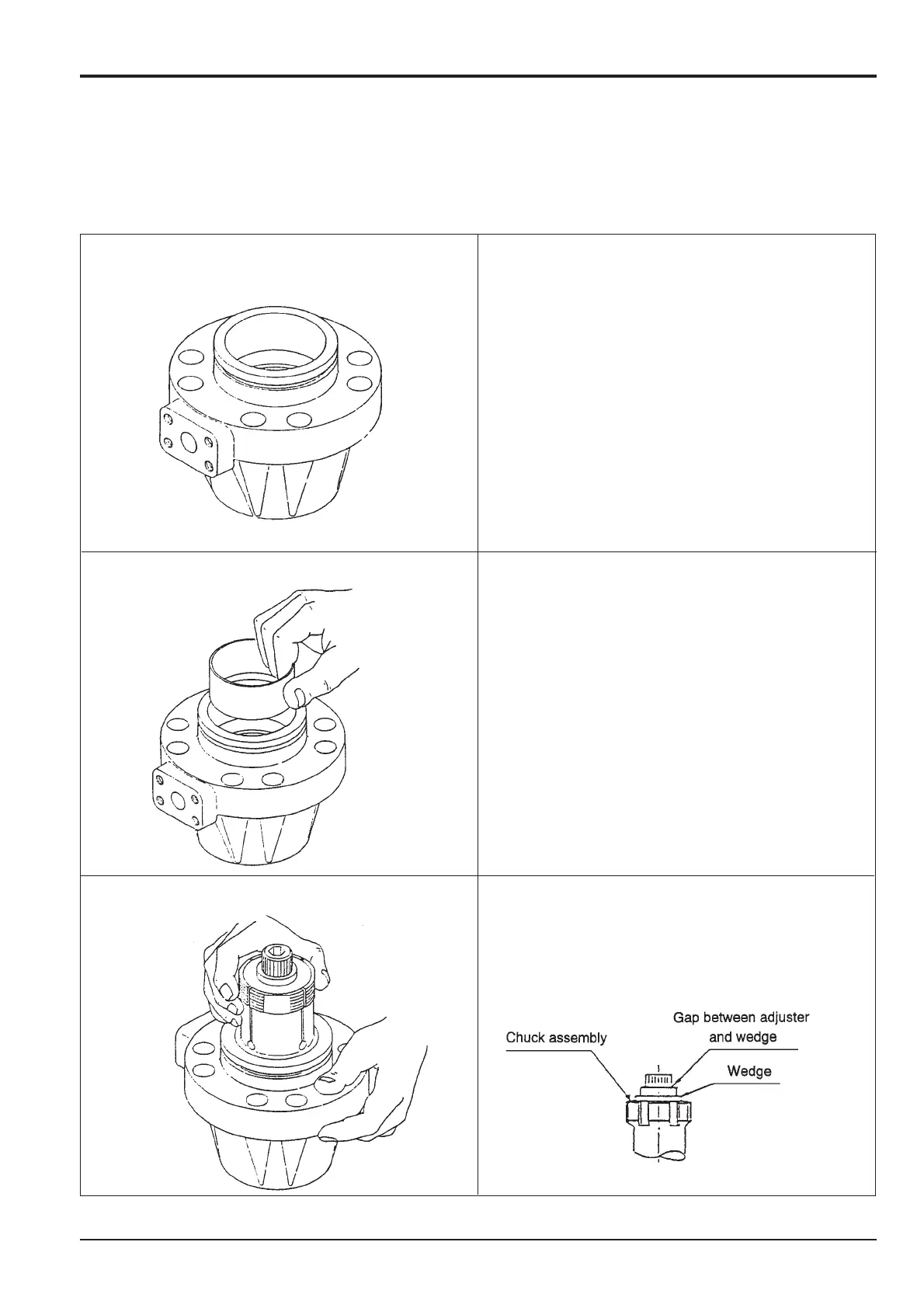

Temporarily place the bushing evenly inside the cylinder

head inner diameter.

Check that there is no foreign matter adhering to the inner

and outer peripheral surfaces.

Supporting the chuck assembly with your fingers,

gradually attach it to the cylinder head.

Check that there is no gap between the chuck assembly

adjuster and wedge.

1 Cylinder head setting

2 Temporary setting of bushing

3 Attaching chuck assembly

JS02230

Loading...

Loading...