92 - 7

Motor Assembly/Cylinder Assembly

Assembly

Refer to the sectional drawing on page 83 - 1 as a guide to

dismantling and assembling.

Check all parts before assembly and remove any scratches

with a fine oil stone or carborundum paper. Wash with a

suitable solvent and blow dry.

Replace all seals with new ones.

Apply clean hydraulic oil to all sliding faces during assembly.

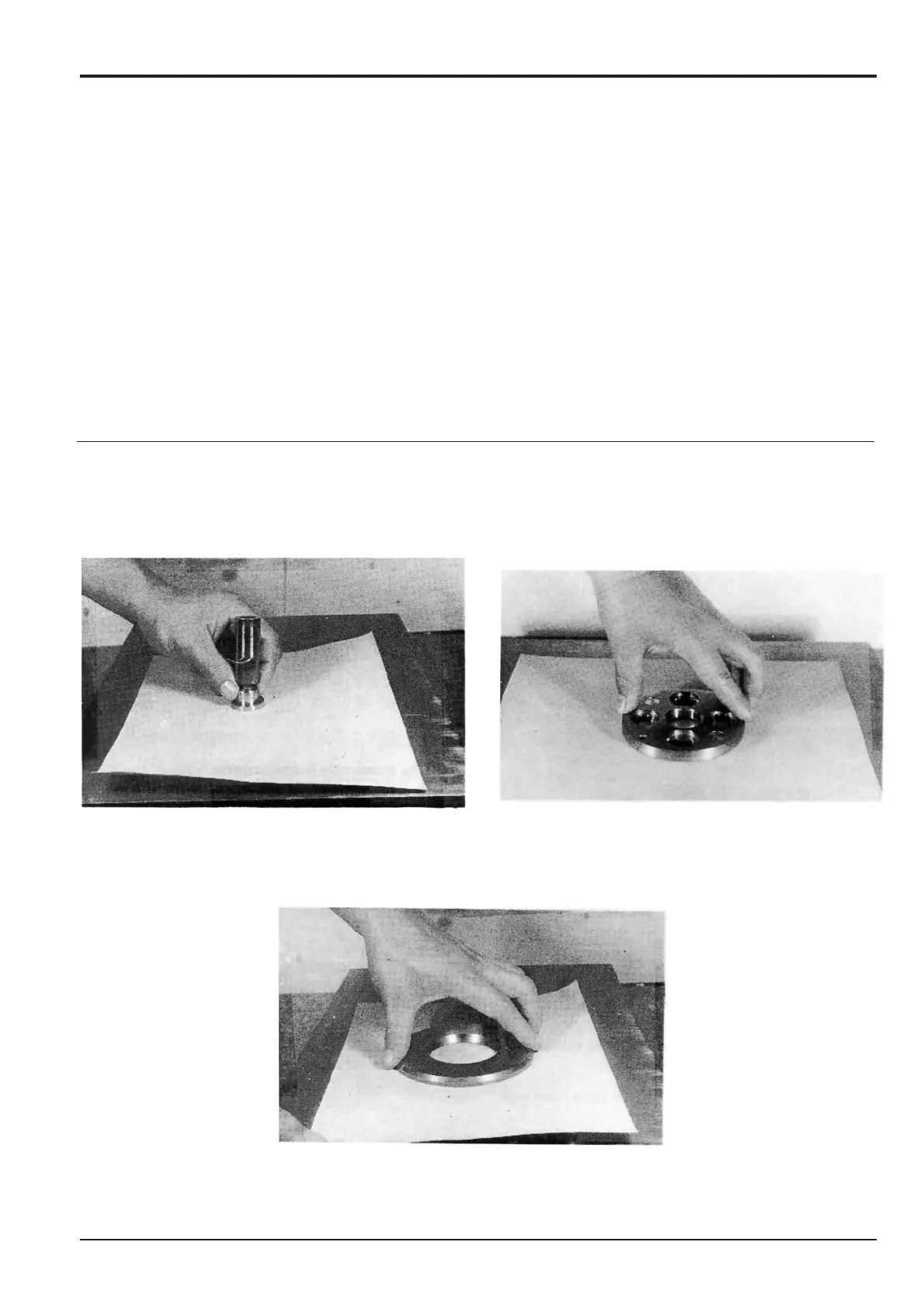

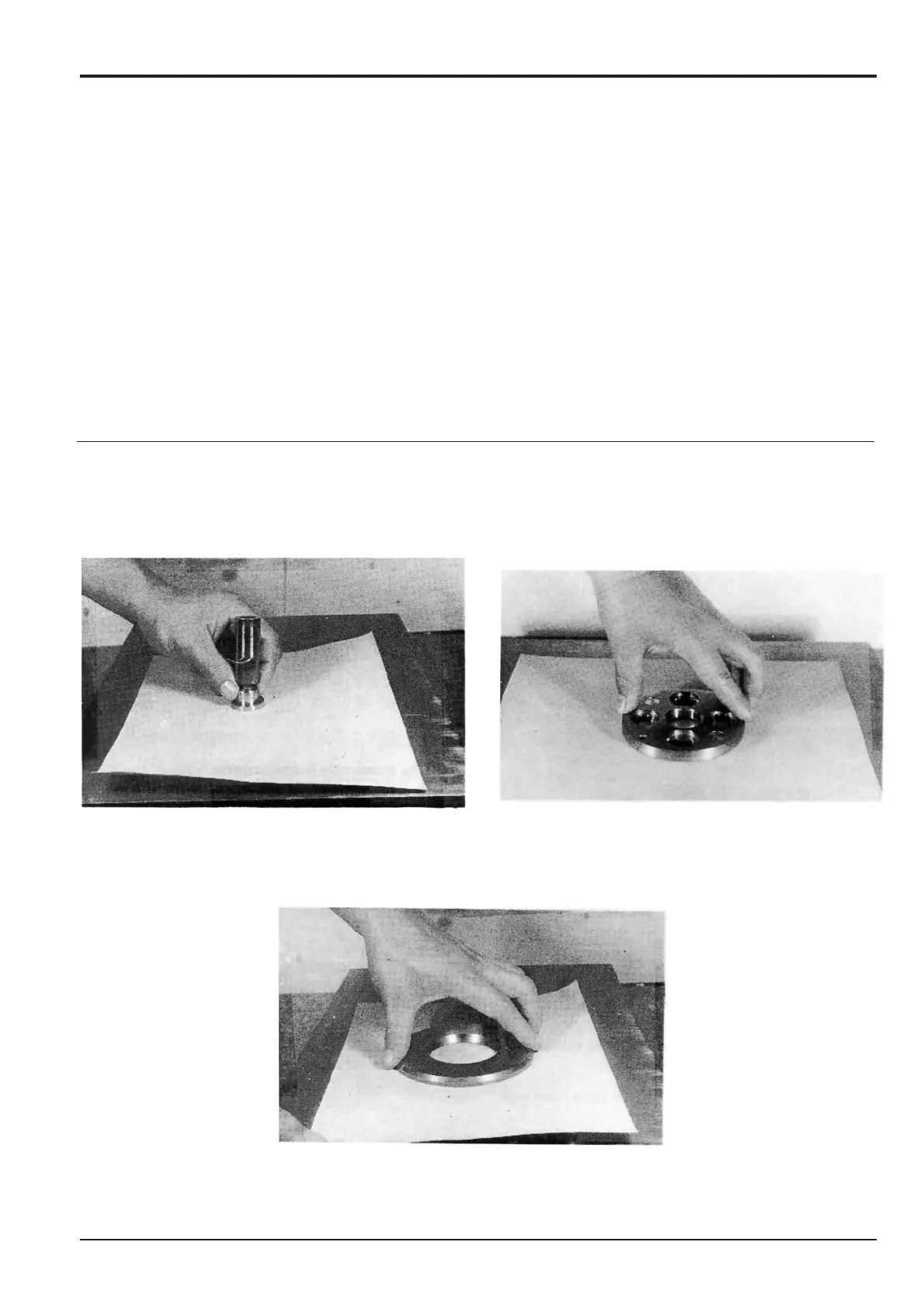

1 Lap the sliding contact faces of piston assemblies 8,

balance plate 21 and swash plate 6 with very fine paste

on a flat surface.

Section E Hydraulics

9803/6410

Section E

92 - 7

Issue 1

Slew Motor

! CAUTION

Cleaning

Cleaning metal parts with incorrect solvents can cause

corrosion. Use only recommended cleaning agents and

solvents.

INT-3-2-11

! CAUTION

‘O’-rings, Seals and Gaskets

Badly fitted, damaged or rotted ‘O’-rings, seals and

gaskets can cause leakages and possible accidents.

Renew whenever disturbed unless otherwise instructed.

Do not use Trichloroethane or paint thinners near ‘O’-

rings and seals.

INT-3-2-12

Loading...

Loading...