12

4. Hold bottom nut (L

2

) to prevent it turning further,

and retighten top nut (L

1

).

5. Repeat above steps for opposite blade guide

assembly.

7.7 Blade tracking

Blade tracking adjustment

requires running saw with back cover open. This

adjustment must be completed by qualified

persons only. Failure to comply may cause

serious injury.

Blade tracking has been set by the manufacturer

and should not need immediate adjustment. If blade

tracking should ever require adjustment:

1. Confirm that blade tension is set properly. To

adjust, see sect. 7.4, Blade tension.

2. Set saw to lowest speed (sect. 7.2).

3. Raise bow to vertical position and secure in

place with support (R, Figure 7).

4. Confirm that blade tension is set properly. To

adjust, see sect. 7.4, Blade tension.

5. Open blade cover.

6. Run saw and observe blade. Blade should run

next to but not tightly against wheel flange.

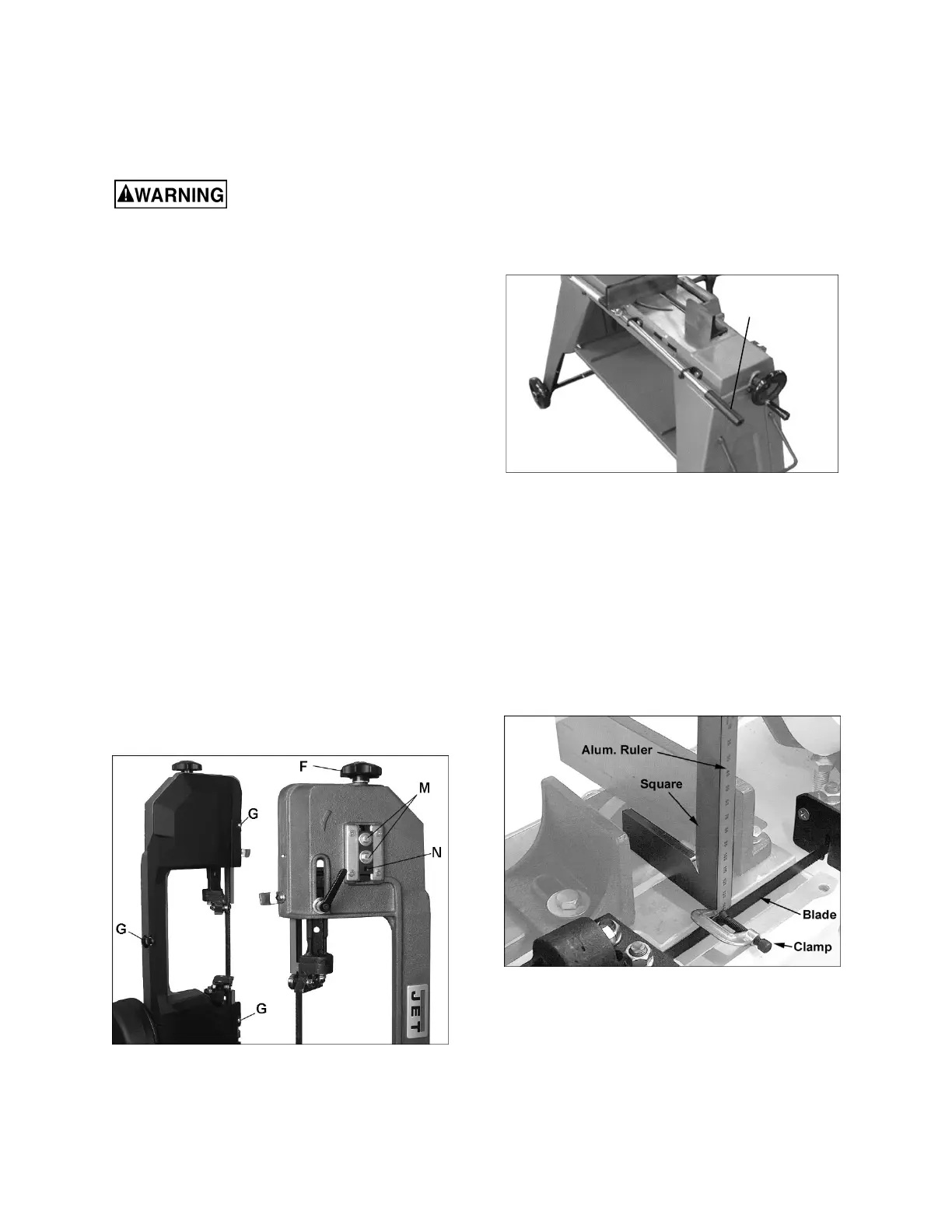

7. Loosen bolts (M, Figure 18) with 12mm wrench.

8. Turn set screw (N) with 4mm hex key, while

observing blade tracking on wheel. Turn set

screw clockwise to track closer to wheel flange.

Turn set screw counterclockwise to track away

from wheel flange. NOTE: This adjustment is

sensitive; start with 1/4 turns on the set screw

and allow blade to respond to changes.

9. Once tracking is set, tighten bolts (M).

Figure 18

7.8 Feed pressure adjustment

Turn handle (O, Figure 19) clockwise to decrease

feed pressure; counterclockwise to increase feed

pressure.

A good indication of proper feed pressure is the

color and shape of the cutting chips. If the chips are

thin or powdered, increase feed pressure. If the

chips are burned and heavy, decrease feed

pressure. If they are still burned and heavy, reduce

blade speed. Optimum feed pressure has been set

when the chips are curled, silvery, and warm.

Figure 19

7.9 Blade-to-table squareness

The blade must be perpendicular to table to ensure

a straight cut. This setting should be checked.

Special blade setting gauges can be purchased for

this type of inspection; however, it can also be done

using more common shop items, as follows.

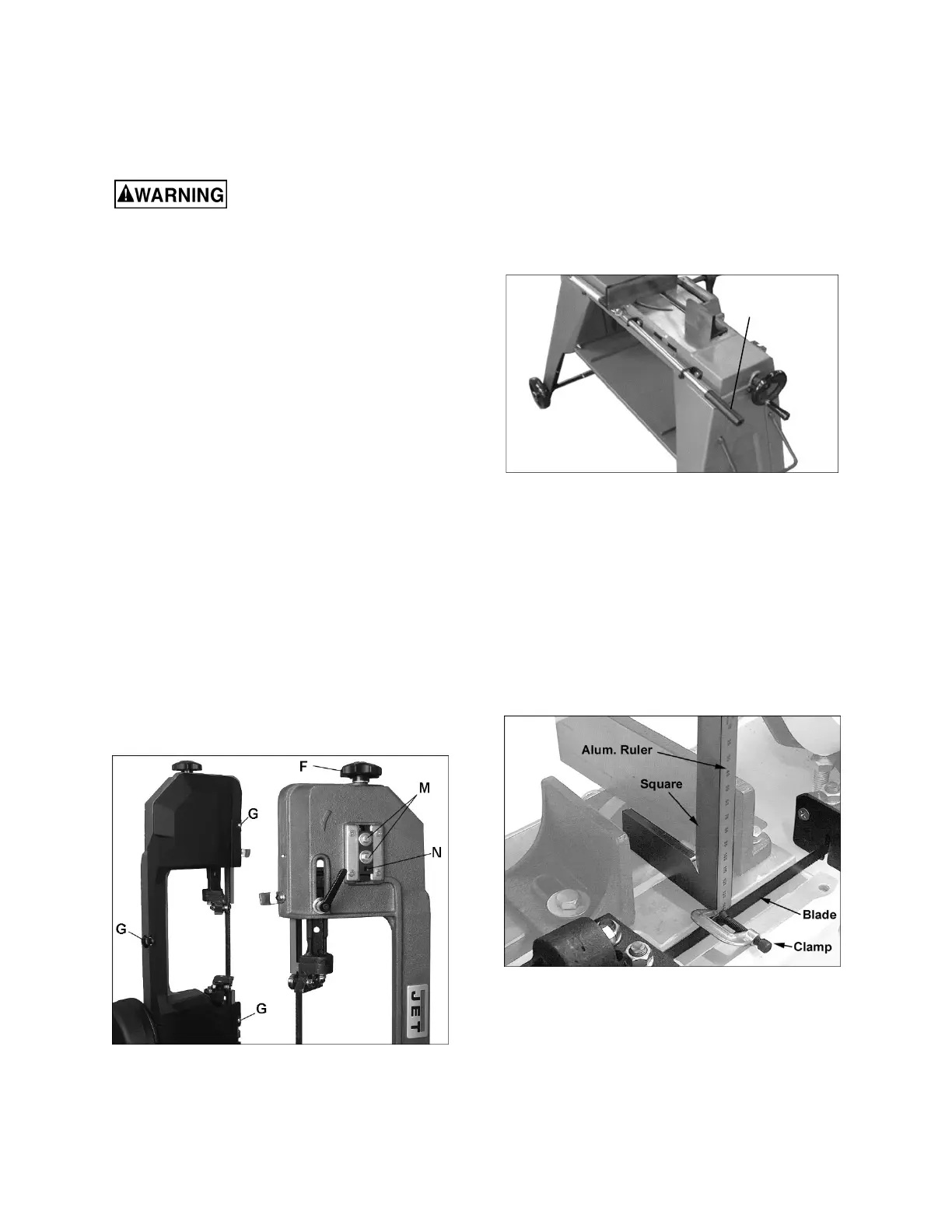

1. “Extend” the surface of blade by clamping a

straight, flat object to blade. (Figure 20 uses a

small, lightweight aluminum ruler.) Use a

lightweight clamp.

Figure 20

2. Place a square on table and against ruler. The

square should lie flat against ruler without a

gap.

3. If there is a gap, loosen bolt (H, Figure 17) on

each blade guide assembly and rotate blade

guide assembly until gap is eliminated between

square and ruler.

4. Retighten bolts (H, Figure 17).

O

Loading...

Loading...