14

8.7 Chip brush

The wire chip brush must be properly adjusted and

maintained in working condition; otherwise damage

to blade can occur. Adjust brush so that its bristles

overlap blade.

Replace brush if it becomes worn or damaged.

8.8 Blade tension

1. Disconnect machine from power source.

2. Open rear guard by removing 2 knobs (see

Figure 8-10). Observe position of blade on

wheel. If blade is not adjacent to wheel flange,

first adjust blade tracking according to sect. 8.9

Blade tracking.

3. If blade is properly adjacent to wheel flange,

slide blade guide assemblies as far apart as

possible, and tighten in position with knobs (N,

Figure 8-7).

4. Push on blade to test tension. Finger pressure

should cause approximately 0.004" deflection.

Turn blade tension handle (P, Figure 8-7) until

proper tension is achieved. For more precise

measurement use blade tension gauge (not

provided).

5. Return blade guides to operating position.

8.9 Blade tracking

Blade tracking adjustment

requires running saw with rear guard open. This

adjustment must be completed by qualified

persons only. Failure to comply may cause

serious injury.

Blade tracking has been set by the manufacturer

and should not need immediate adjustment. If blade

tracking should ever require adjustment:

1. Confirm that blade tension is properly set.

2. Set saw to slowest speed.

3. Raise bow to vertical position.

4. Open blade cover.

While performing the

following steps, keep blade from rubbing

excessively on wheel shoulder. Excessive

rubbing will damage wheel and/or blade.

5. Run saw and observe blade. Blade should run

next to but not tightly against wheel shoulder.

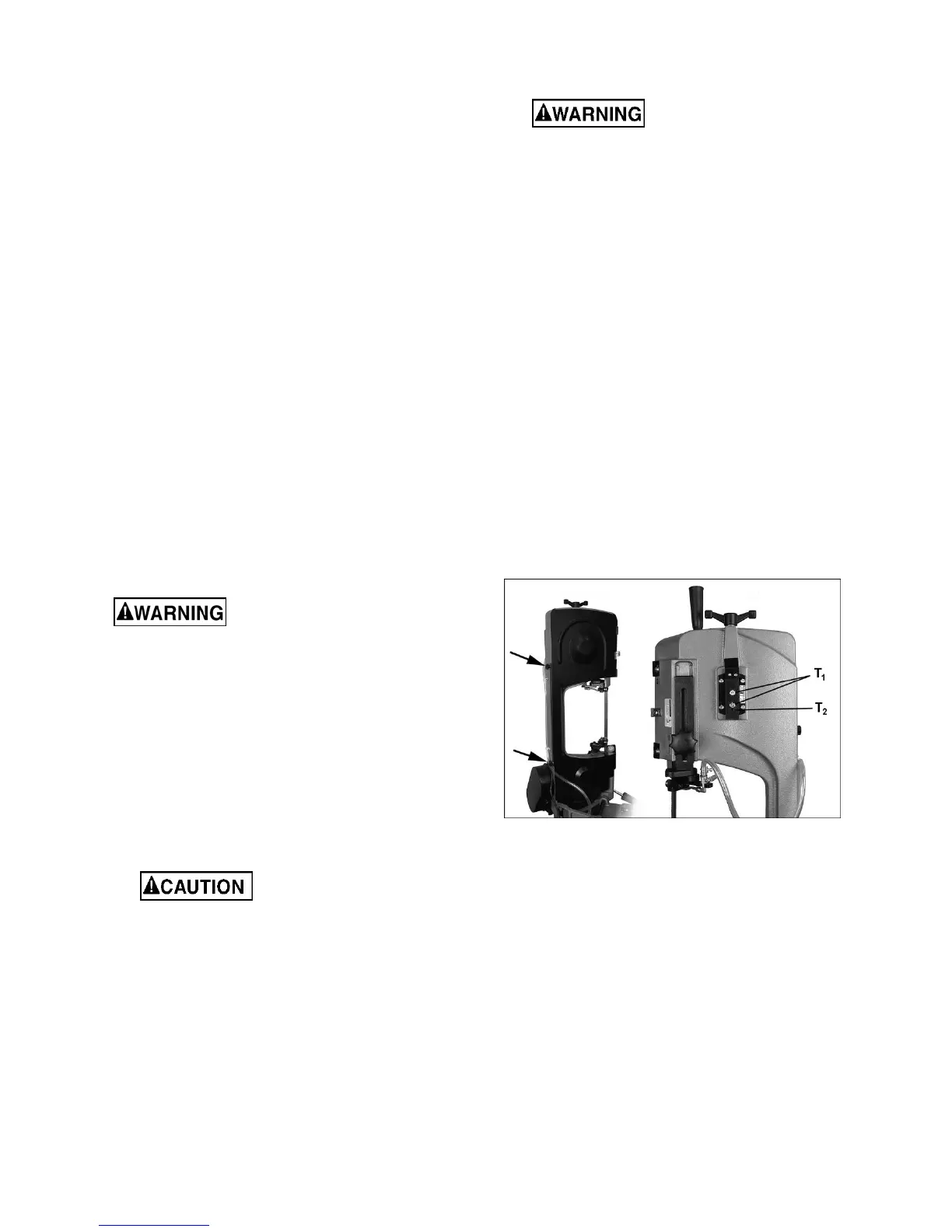

6. If blade is not tracking properly, loosen bolts (T

1

,

Figure 8-10) with 12mm wrench.

7. Turn set screw (T

2

) with 4mm hex key, while

observing blade tracking on wheel. Turn set

screw clockwise to track closer to wheel

shoulder. Turn set screw counterclockwise to

track away from wheel shoulder. NOTE: This

adjustment is sensitive; start with 1/4-turns on

set screw and allow blade to respond to

changes.

Keep fingers clear of blade

and wheel to avoid injury.

8. Test the setting by placing a six-inch length of

paper between blade and wheel. The paper

should not be cut as it passes between wheel

shoulder and blade.

9. Turn set screw (T

2

) a small amount. Repeat

insertion of paper between the shoulder and the

blade until paper is cut into two pieces.

NOTE: You may have to repeat the check with

the paper several times before blade and

shoulder cut the paper into two pieces. Do not

hurry the adjustment. Patience and accuracy

here will pay off with better, more accurate,

quieter cutting and longer machine and blade

life.

10. When paper is cut, back off set screw slightly.

This assures that blade is not touching wheel

shoulder.

IMPORTANT: If blade is allowed to run against

wheel shoulder, it will wear off the shoulder.

11. Once tracking is set, tighten bolts (T

1

).

Figure 8-10: blade tracking adjustment

8.10 Test cut to verify adjustment

Test cuts can be used to determine whether or not

you have adjusted the blade accurately. Use 2-inch

round bar stock to perform these test cuts, as

follows:

1. With bar stock securely clamped in vise, make

a cut through the bar stock. (See Figure 8-11.)

2. Mark the top of bar stock.

3. Move the bar stock about 1/4-inch past the

blade so that you can begin a second cut.

4. Rotate the bar stock 180 degrees so mark you

made is now at bottom of cut.

5. Make a cut through the bar stock.

Loading...

Loading...